Flange assembly with frangible gate for mounting air cannons to bulk material processing equipment

A technology for bulk materials and processing equipment, applied in mechanical equipment, flange connections, packaging, etc., which can solve problems such as the danger of air cannon installation, hindering the installation of air cannons, and interrupting the processing/handling of bulk materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

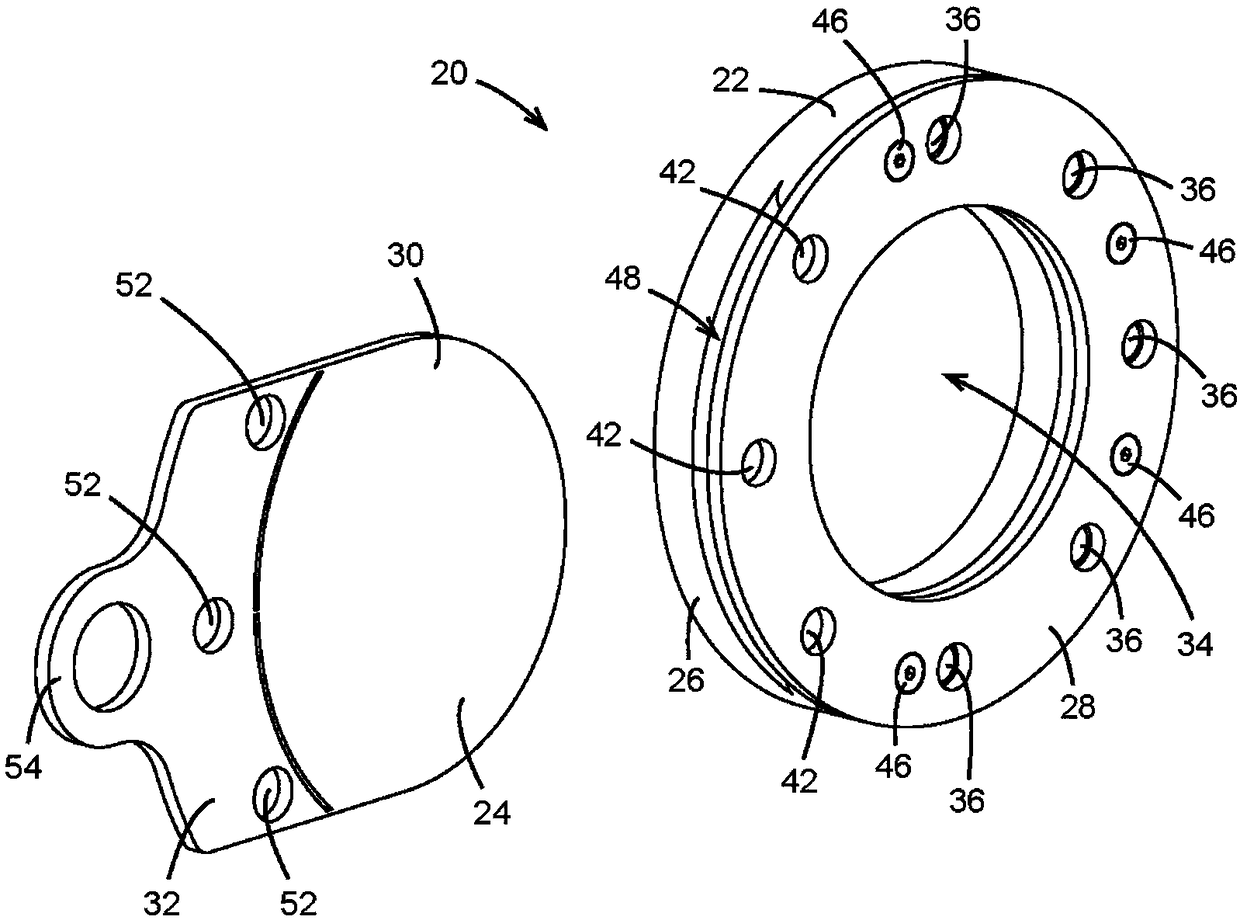

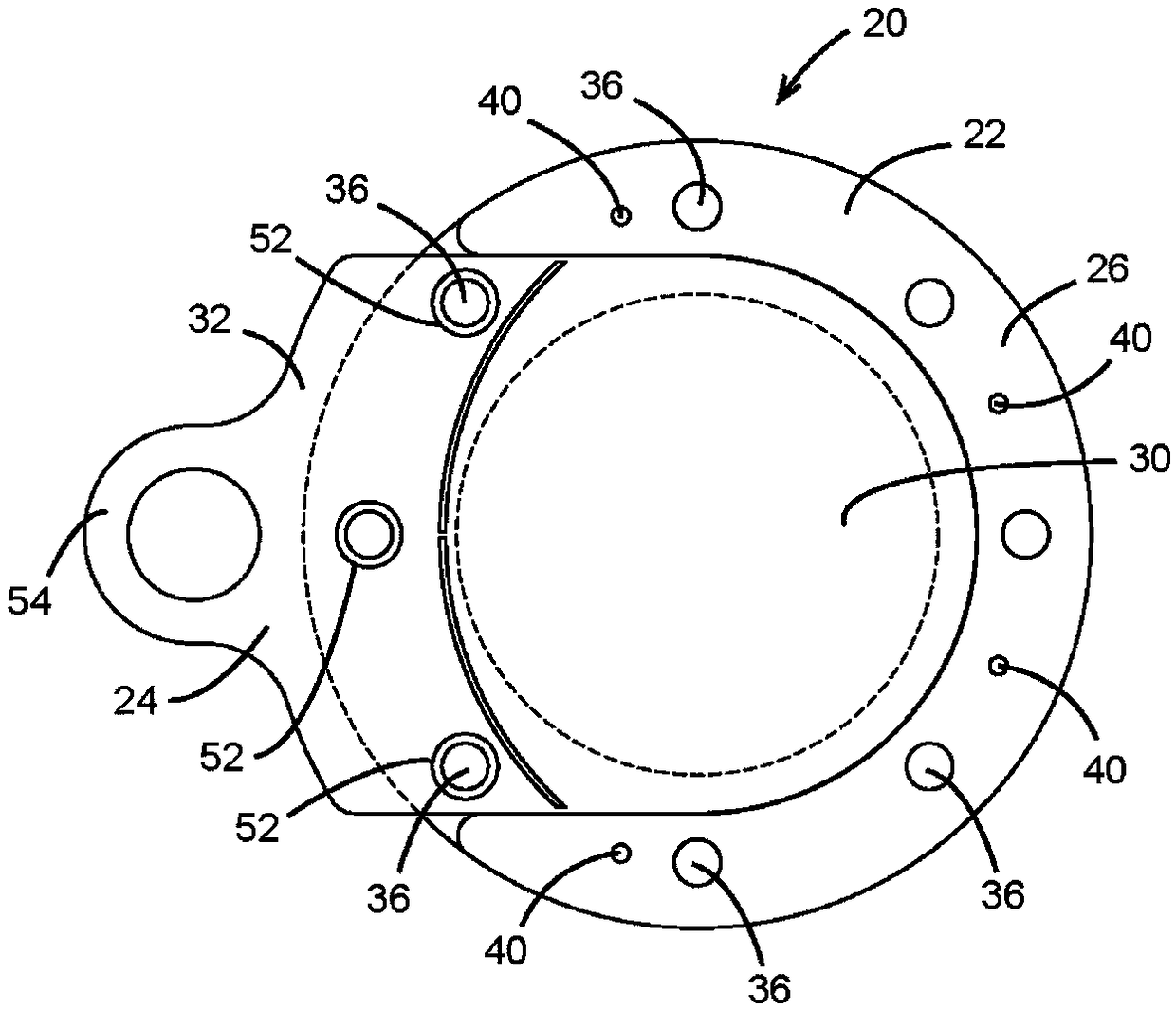

[0027] figure 1 A partially exploded view of a preferred embodiment of the flange assembly (20) according to the invention is shown in . The flange includes a mounting ring (22) and a gate (24). The mounting ring (22) includes a primary portion (26) and a secondary portion (28). The gate (24) includes a blocking portion (30) frangibly connected to a flange portion (32).

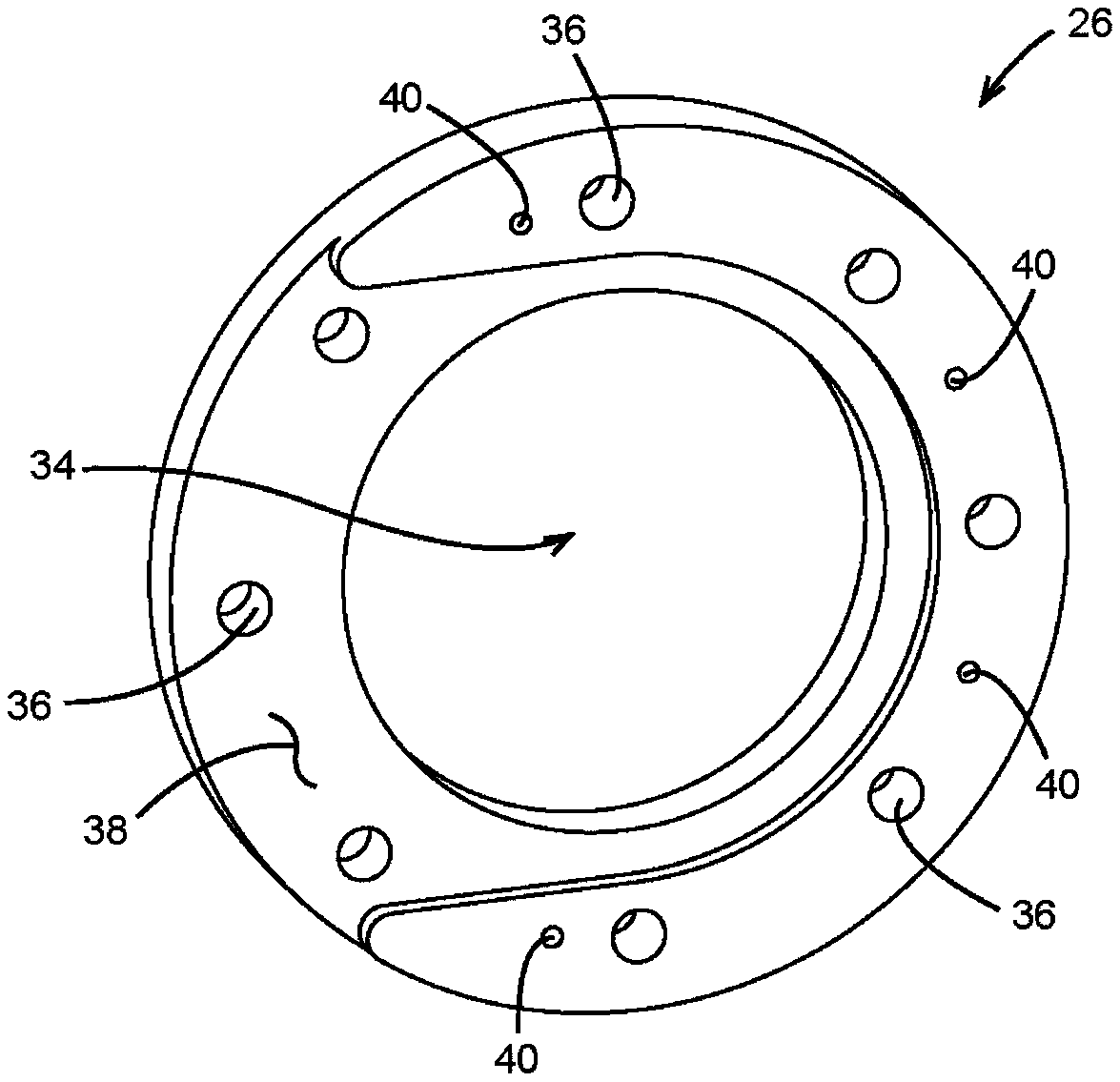

[0028] The main portion (26) of the mounting ring (22) is annular and surrounds the fluid passage (34). The main portion (26) of the mounting ring (22) includes a plurality of threaded bolt holes (36) spaced circumferentially about and parallel to the fluid passage (34). The main portion (26) of the mounting ring (22) also includes a notch (38) configured to receive the blocking portion (30) of the gate (24). The notch (38) preferably extends around the boundary of the fluid channel (34). Furthermore, the main portion (26) of the mounting ring (22) includes at least two threaded screw holes (40) formed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com