Foam extinguishing agent stirring device driven by cycloidal pin gear speed reducer

A technology of cycloidal pinwheel deceleration and foam fire extinguishing agent, which is applied to mixers with rotating stirring devices, mixer accessories, mixers, etc. The proportion of liquid raw materials and other issues can achieve the effect of good after-killing effect, eliminating potential safety hazards and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the purpose and technical solution of the present invention clearer, the technical solution of the present invention will be clearly and completely described below in conjunction with the embodiments of the present invention.

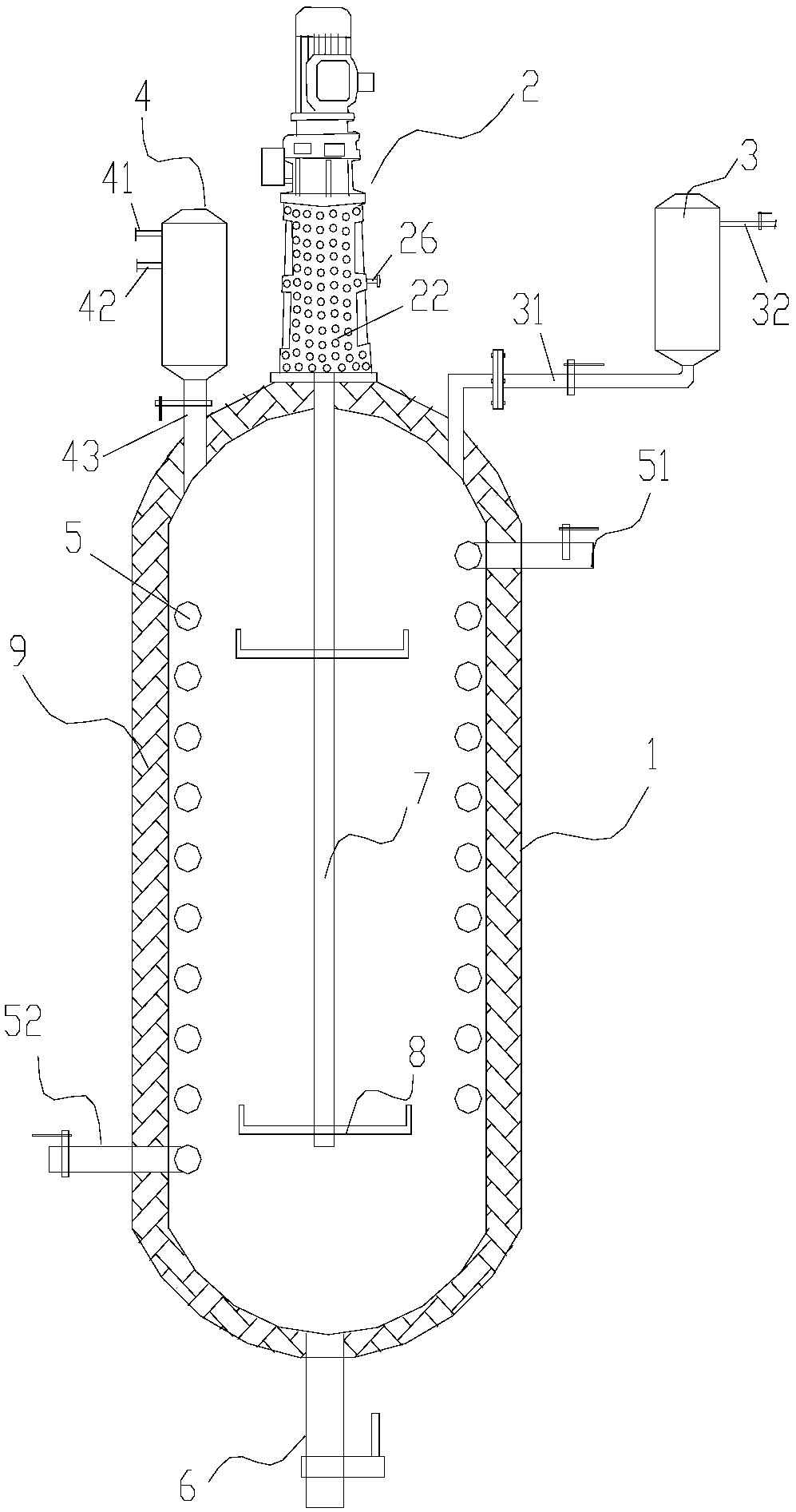

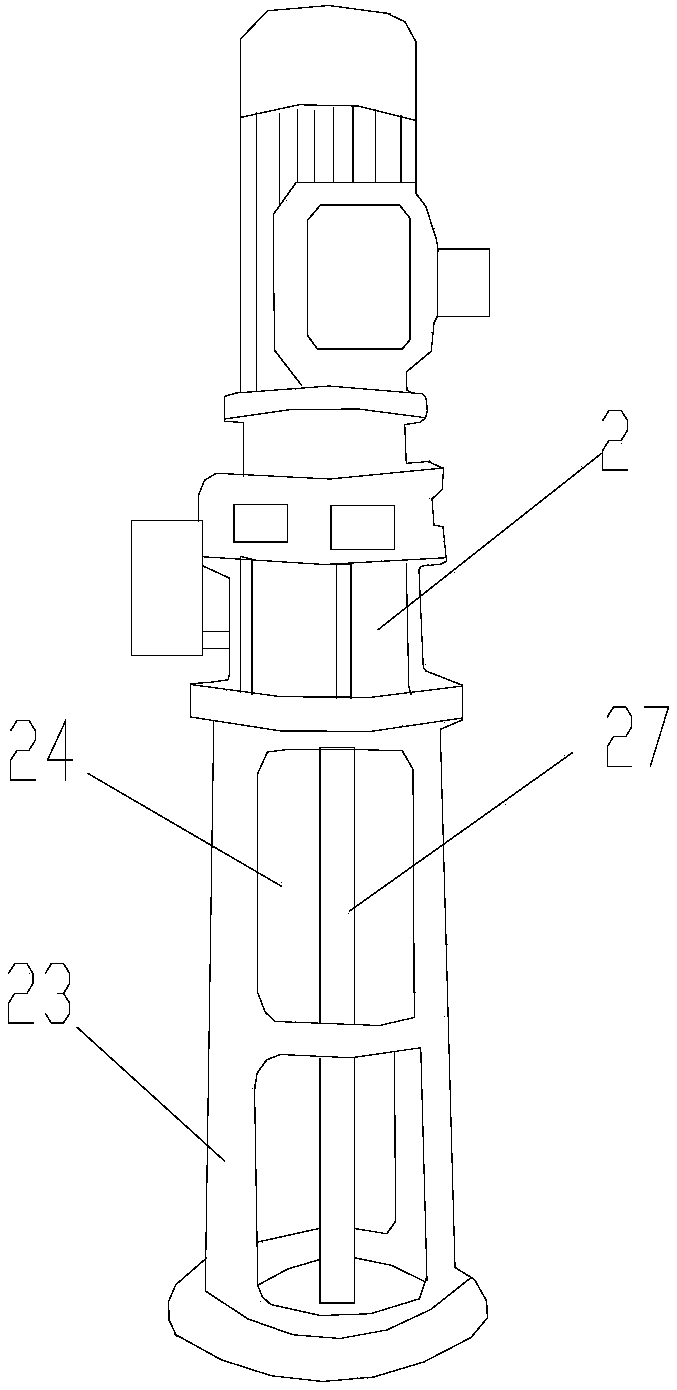

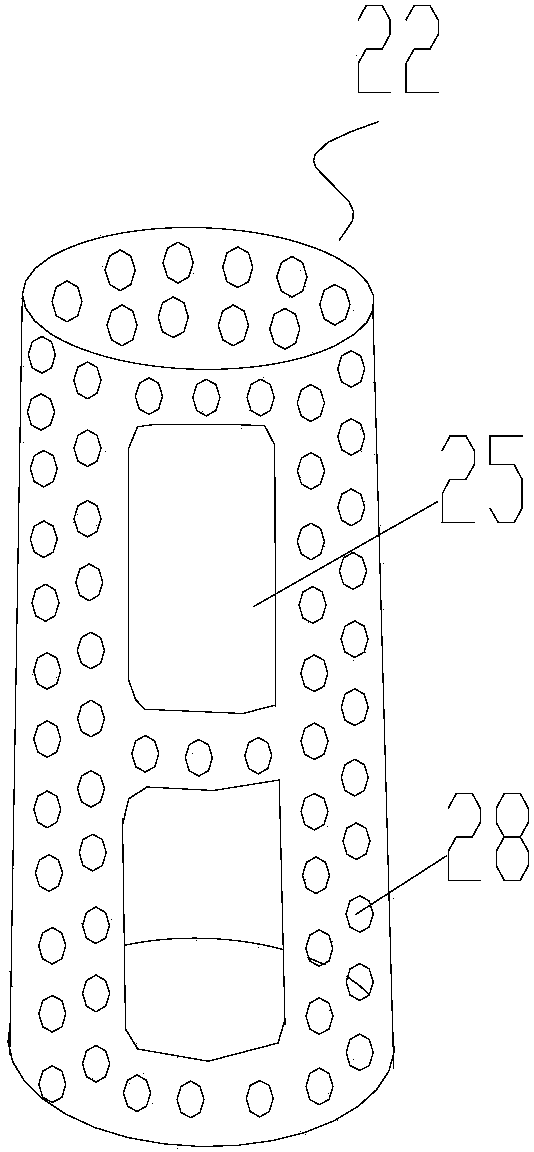

[0027] Such as Figure 1-5 As shown, a foam fire extinguishing agent stirring device driven by a cycloidal pinwheel reducer includes a stirring tank body 1, a sealed solid feeding tank 4 and a liquid feeding tank 3; machine 2, the output shaft 27 of the cycloidal pinwheel reducer 2 is fixedly connected with the stirring shaft 7, and the stirring shaft 7 is located in the stirring tank body 1; the stirring shaft 7 is provided with two groups of stirring blades 8, and the stirring shaft 7 The bottom is provided with a first discharge pipe 6, and the first discharge pipe 6 is provided with a first valve; the upper part of the sealed solid feeding tank 4 is connected with a vacuum tube 41 and a feed tube 42, and the vacuum tube 41 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com