Wooden door frame automatic assembling equipment

A framework and automatic technology, applied in the direction of wood processing equipment, manufacturing tools, etc., can solve the problems of difficulty in meeting the needs of mass customization, inability to adapt to the needs of intelligent and digital production, and high labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

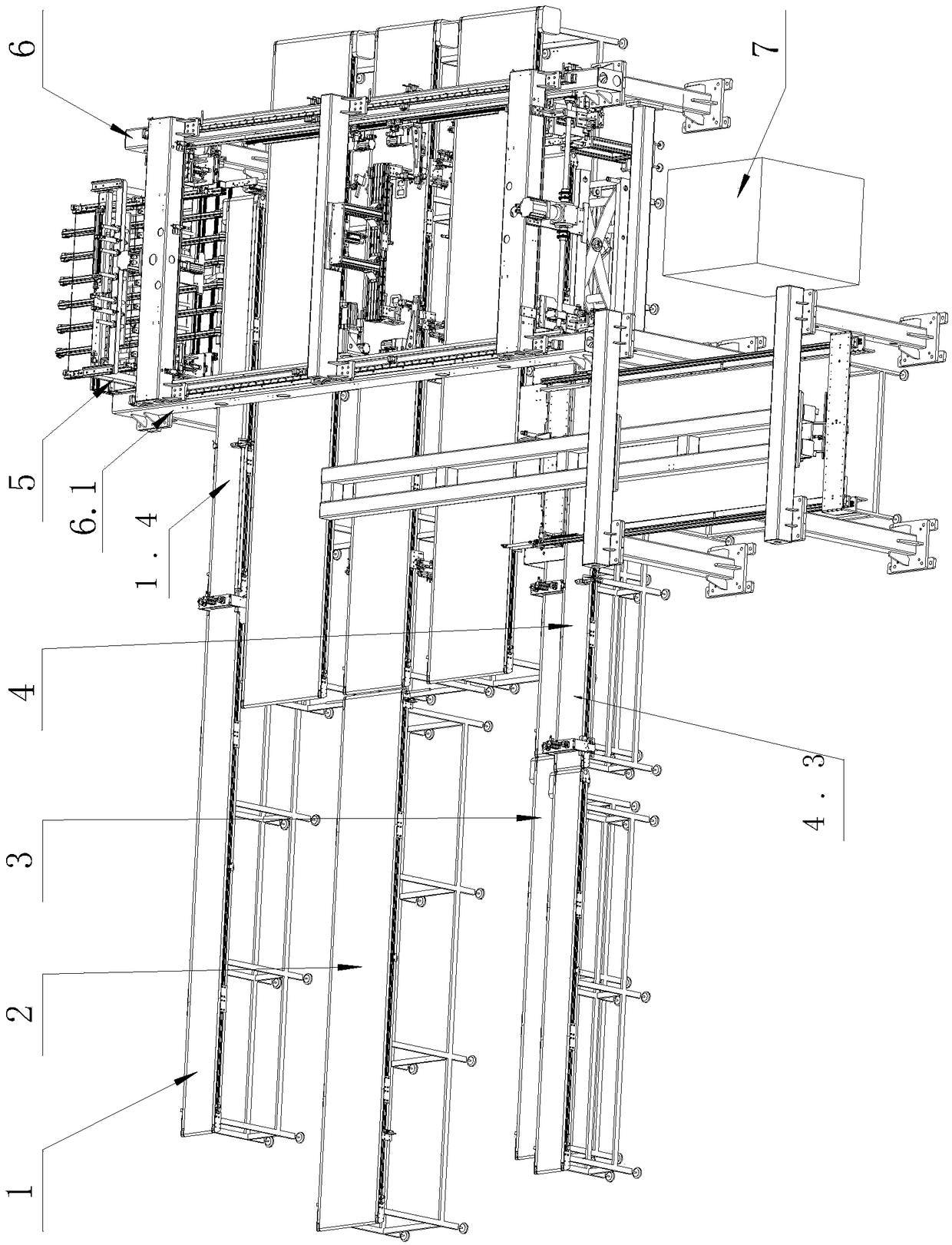

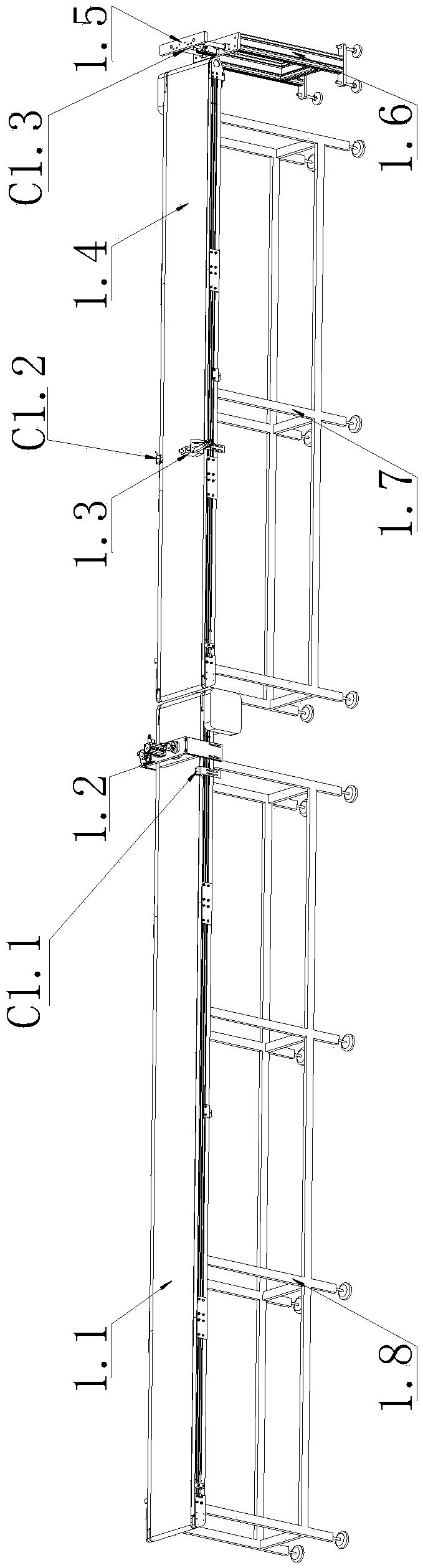

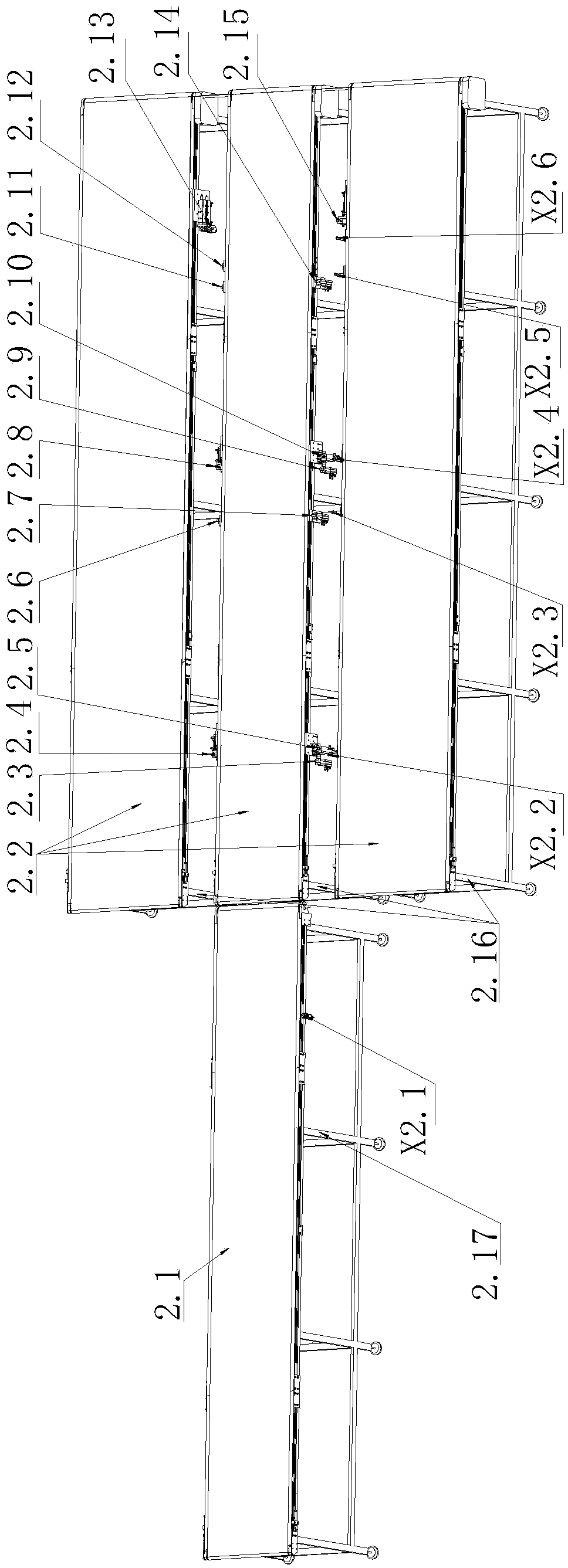

[0027] Such as Figure 1-20 As shown, the present invention includes A upper dock conveying assembly 1, B side court and frame conveying assembly 2, C lower dock conveying assembly 3, D conveying pre-installed assembly 4, E glass box conveying assembly 5, F frame Final assembly 6, G glue supply system 7. Among them, since there are many identical parts or small parts in each part of the whole machine, in order to distinguish which big part these parts or small parts belong to, first of all, A, B, C, D, The letters E, F, and G respectively represent the number of the large parts represented by the subsequent numbers. The number here is just a difference in description, and does not represent the importance of the parts they represent. Similarly, FA manipulator IV and FB manipulator I represent two di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com