A variable stiffness elastic energy storage device and a method for testing rock instability using it

A technology of energy storage device and variable stiffness, which is applied in the direction of testing material strength by applying stable shear force, measuring device, and testing material strength by applying stable tension/pressure to achieve the effect of reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

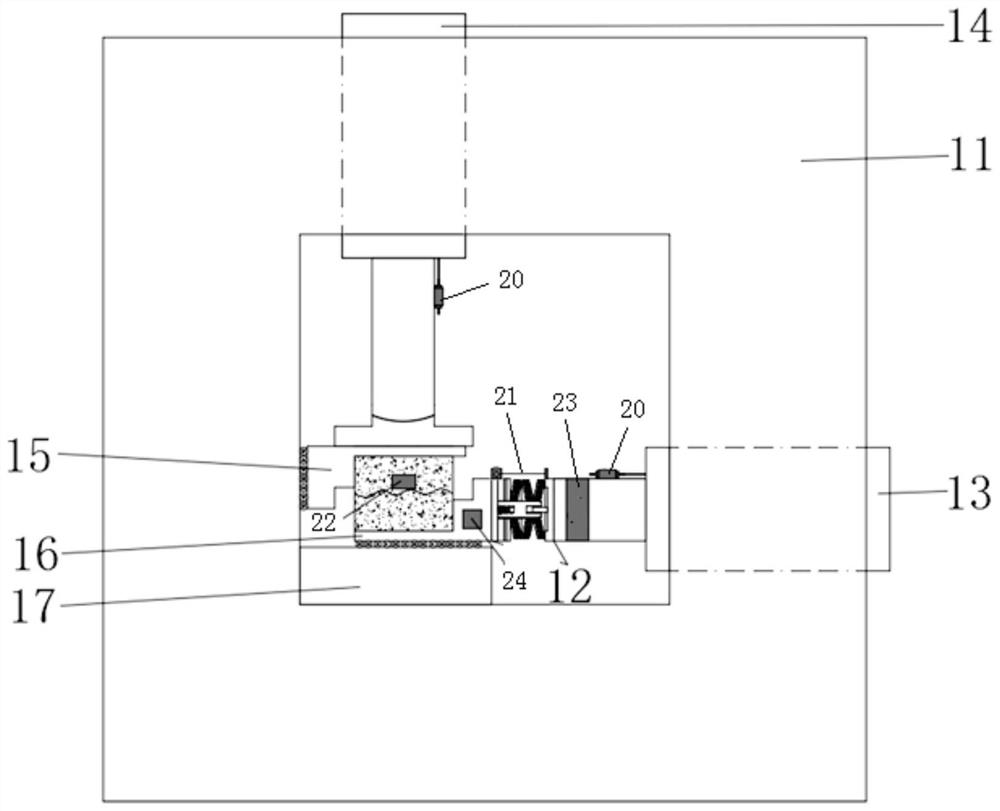

[0042] Such as figure 2As shown, a rock joint shear instability testing machine is an application of a variable stiffness elastic energy storage device on a conventional shear testing machine. It is composed of a conventional rock joint shear instrument and a variable stiffness elastic energy storage device, including a rigid frame structure 11, a variable stiffness elastic energy storage device 12, a tangential loading mechanism 13, a normal loading mechanism 14, an upper clamp 15 and a lower clamp 16 and block 17. The normal loading mechanism 14 is fixed on the upper part of the rigid frame structure 11 , the tangential loading mechanism 13 is fixed on one end of the rigid frame structure 11 , and the spacer 17 is fixed on the lower part of the rigid frame structure 11 . One end of the variable stiffness elastic energy storage device 12 is rigidly connected to the tangential loading mechanism 13 , and the other end is in contact with the lower clamp 16 .

[0043] The spec...

Embodiment 2

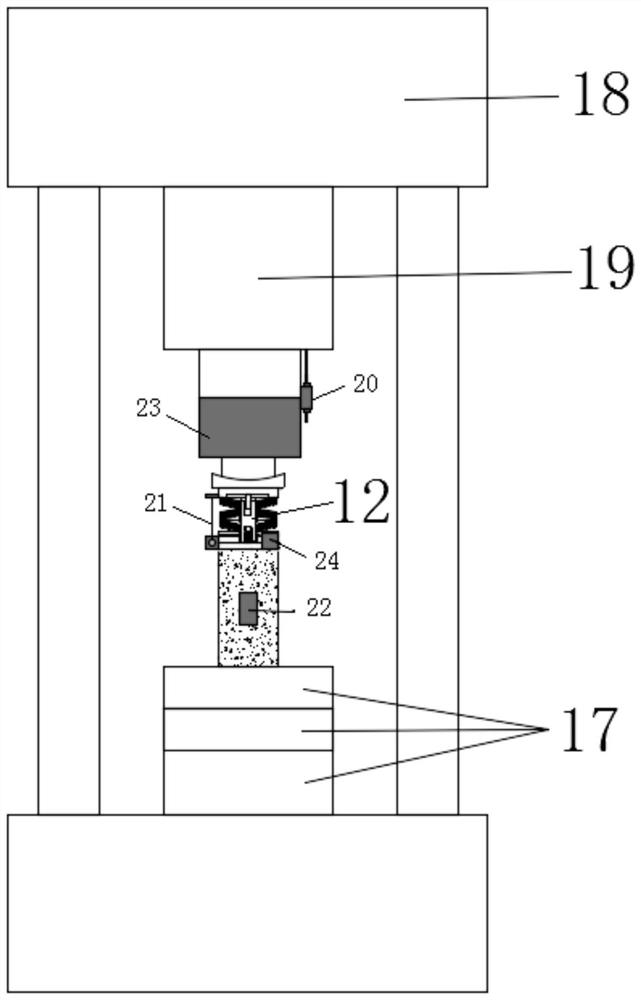

[0059] Such as image 3 As shown, a rock uniaxial compression instability testing machine is the application of the variable stiffness elastic energy storage device on the conventional uniaxial compression testing machine, and is composed of the conventional rock uniaxial compression testing machine and the variable stiffness elastic energy storage device , comprising a body frame 18, a variable stiffness elastic energy storage device 12, a loading cylinder 19, and a spacer 17. The loading oil cylinder 19 and the spacer 17 are fixed on the upper and lower ends of the body frame 18 respectively. One end of the variable stiffness elastic energy storage device 12 is in contact with the loading cylinder 19, and the other end is in contact with the upper surface of the rock sample, which is placed on the pad 17 of the testing machine.

[0060] The specific implementation plan is as follows:

[0061] Step 1: First, prepare a standard cylindrical rock sample;

[0062] Step 2: Plac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com