Electric-shock-proof power socket

A power socket and anti-shock technology, which is applied to circuits, contact parts, electrical components, etc., can solve problems such as electric shock hazards, safety hazards, and children's electric shocks, and achieve the effect of improving safety factors and ensuring life safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

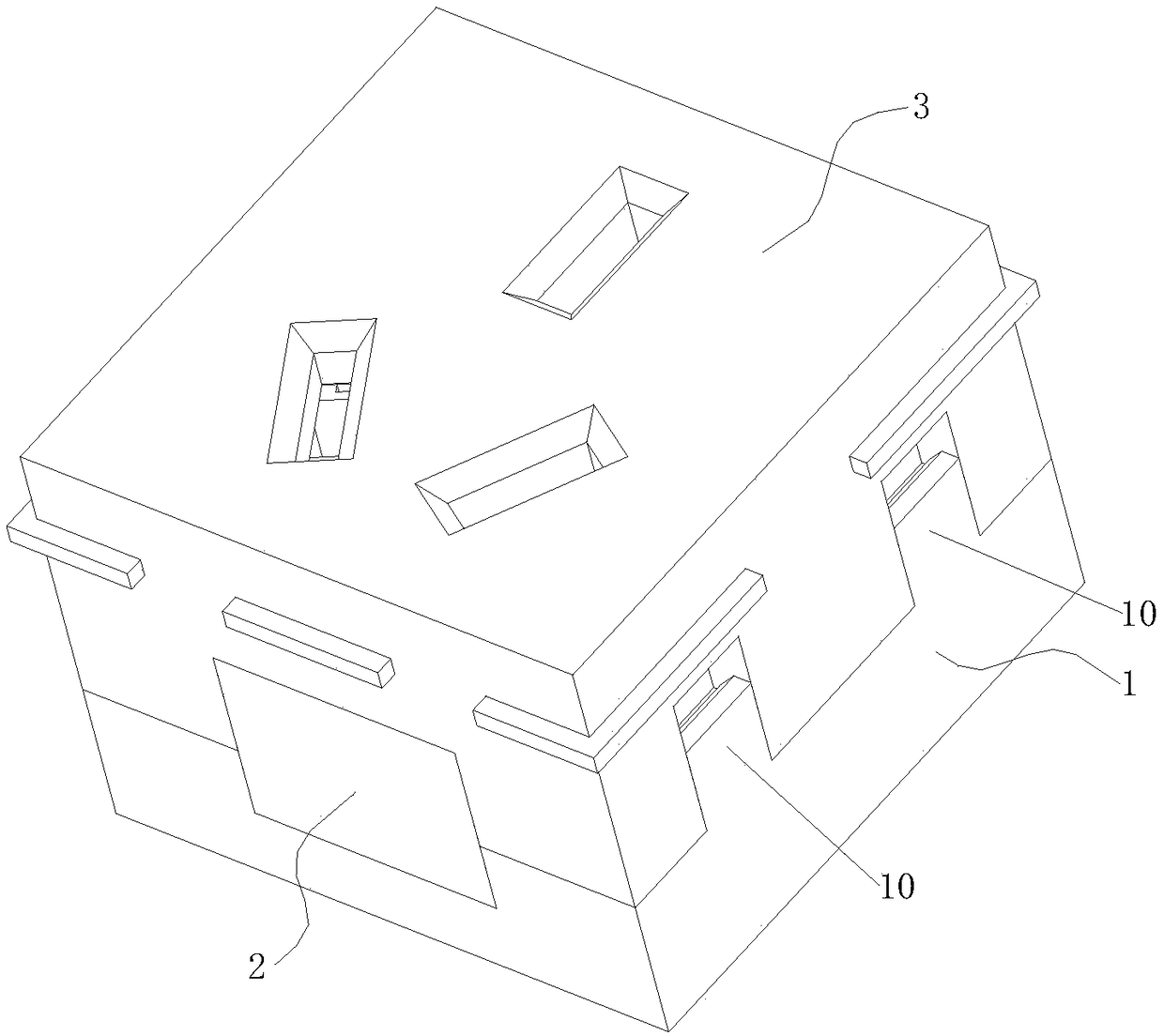

Image

Examples

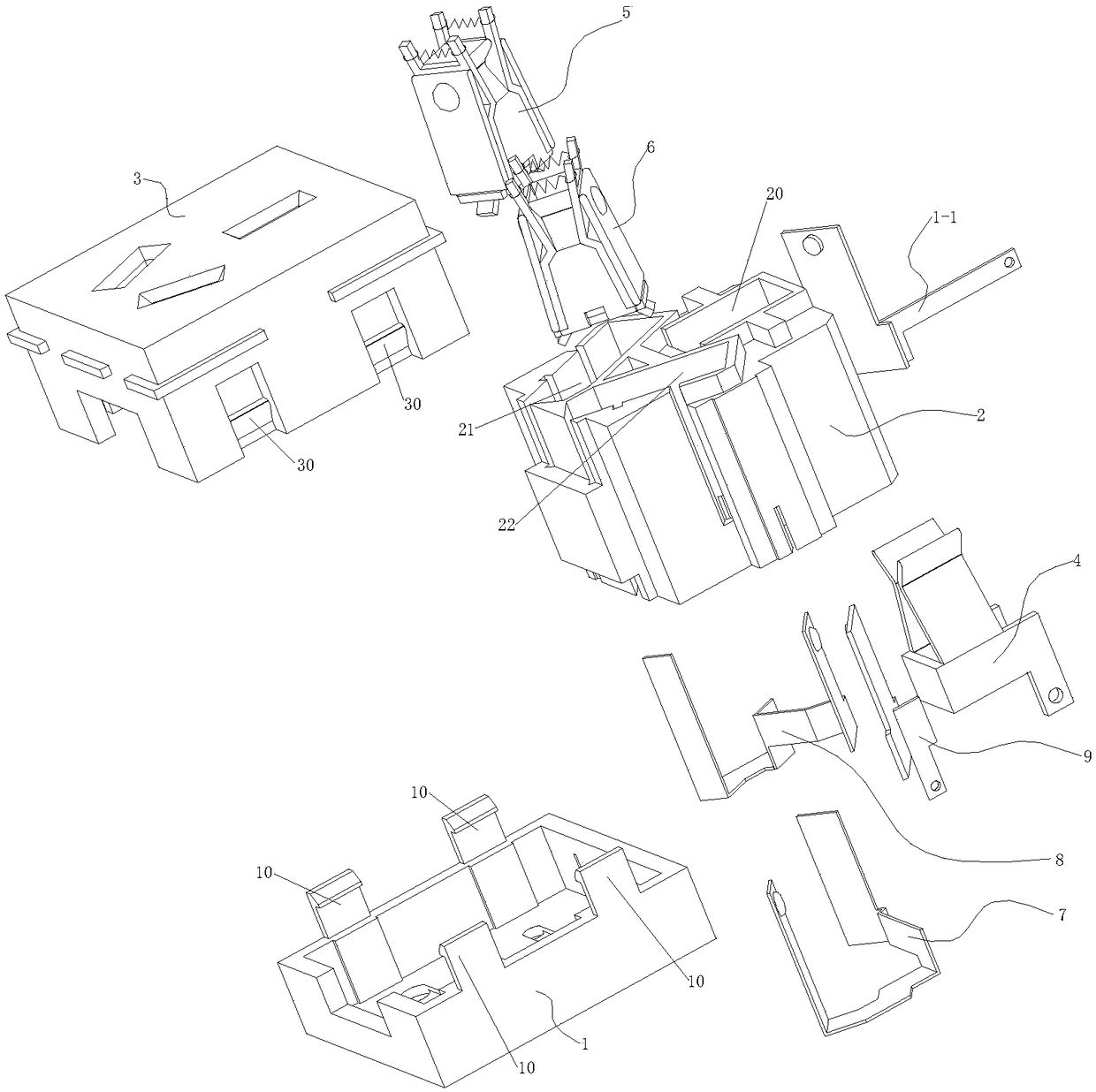

Embodiment 1

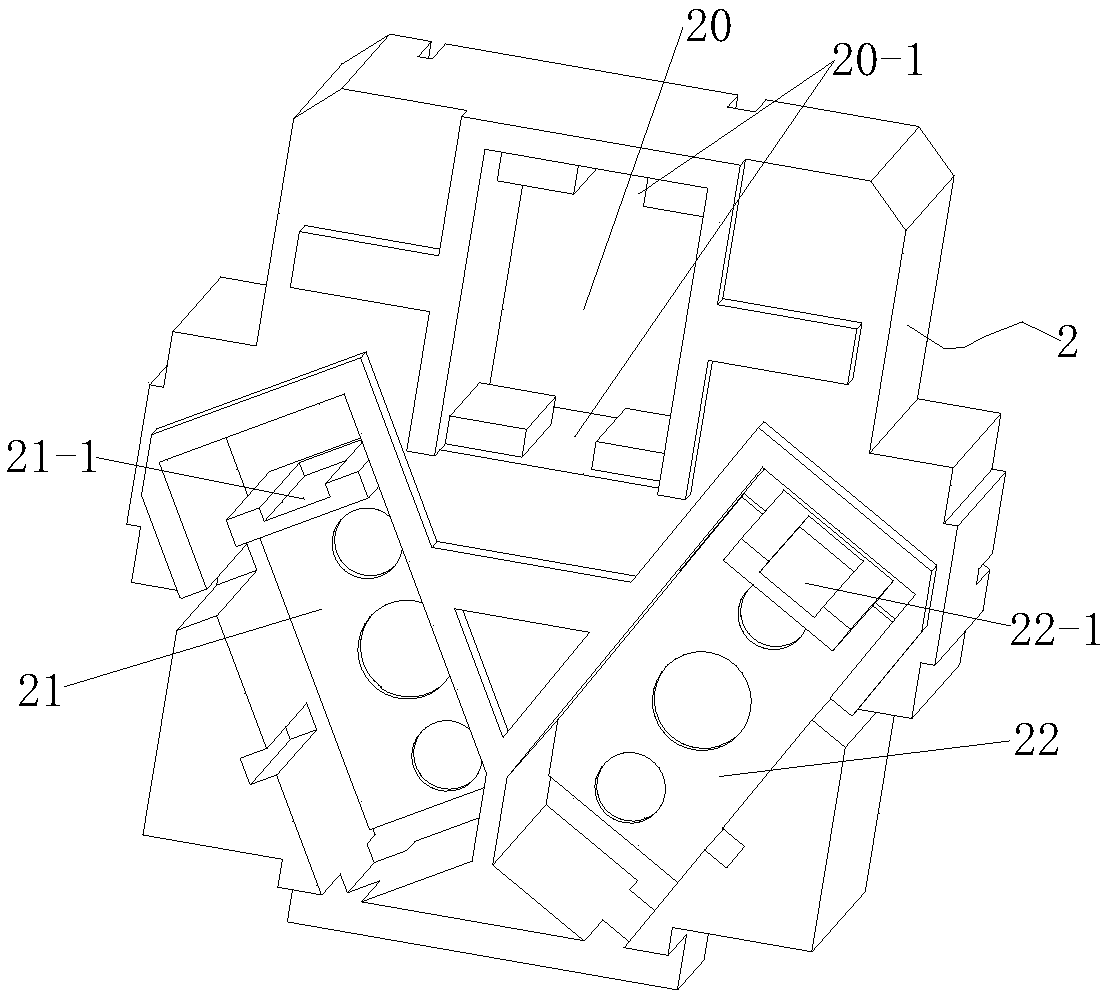

[0044] In this electric shock-proof power socket, pin one 9 is used as the live wire terminal, and pin two 1-1 is used as the neutral terminal. 5 and the negative battery 6, if it is a two-phase socket, only the positive battery 5 and the negative battery 6 are inserted. Here, the three-phase socket in the attached drawing is used as an example, and the metal part of the plug is inserted into the positive battery 5 and the negative battery 6. Negative electrode cell 6. At this time, the metal part of the plug is inserted into the middle electrode sheet 1 of the positive electrode cell 5 and the middle electrode sheet 2 61 of the negative electrode cell 6 respectively. During the insertion process, the positive electrode sheets on both sides 50 is opened, and the negative electrode sheets 60 on both sides are opened. At this time, the upper side of the positive electrode sheet 50 pushes the conductive sheet 1 7 through the separator 21-1 and inserts the upper part of the inner w...

Embodiment 2

[0047] When a child inserts a finger or a metal device into the positive electrode core 5, although the positive electrode sheets 50 on both sides are opened, the upper side of the positive electrode sheet 50 pushes the conductive sheet 7 through the separator 21-1 and inserts it into the positive electrode. The upper part of the inner wall of the slot 21 is in contact with the pin 2 1-1, and the lower side of the positive electrode sheet 50 is directly in contact with the lower part of the inner wall of the positive electrode slot 21 where the conductive sheet 2 8 is inserted, but no finger or metal is inserted into the negative electrode cell 6. Device, that is, the negative electrode sheets 60 on both sides are not opened, and the conductive sheet 2 8 and the pin 9 are separated by the partition plate 2 22-1. At this time, only the pin 9 is charged, and the conductive sheet 2 8 is not charged. Therefore, the positive battery cell 5 is not charged, so it is safe for children ...

Embodiment 3

[0049] When a child inserts a finger or a metal device into the negative electrode core 6, although the negative electrode sheets 60 on both sides are opened, the upper side of the negative electrode sheet 60 pushes the conductive sheet 2 8 through the separator 22-1 and inserts it into the negative electrode. The upper part of the inner wall of the slot 22 is in contact with the pin one 9, and the lower side of the negative electrode sheet 60 is directly in contact with the lower part of the inner wall of the negative electrode slot 22 where the conductive sheet one 7 is inserted, but the conductive sheet two 8 and the pin one 9 are covered by the separator Two 22-1 are separated, the conductive sheet one 7 and the pin two 1-1 are separated by the separator one 21-1, no finger or metal device is inserted into the positive electrode cell 5, that is, the positive electrode sheets 50 on both sides are not covered Open, now only pin one 9 and conductive sheet two 8 are charged, so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com