Combination rib for aircraft wings

An aircraft and airfoil technology, which is applied in the directions of wings, aircraft parts, chords/stringers, etc., can solve the problems of inability to provide process access and poor construction manufacturability, so as to improve the manufacturability and construction efficiency, and solve the problem of poor construction access. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

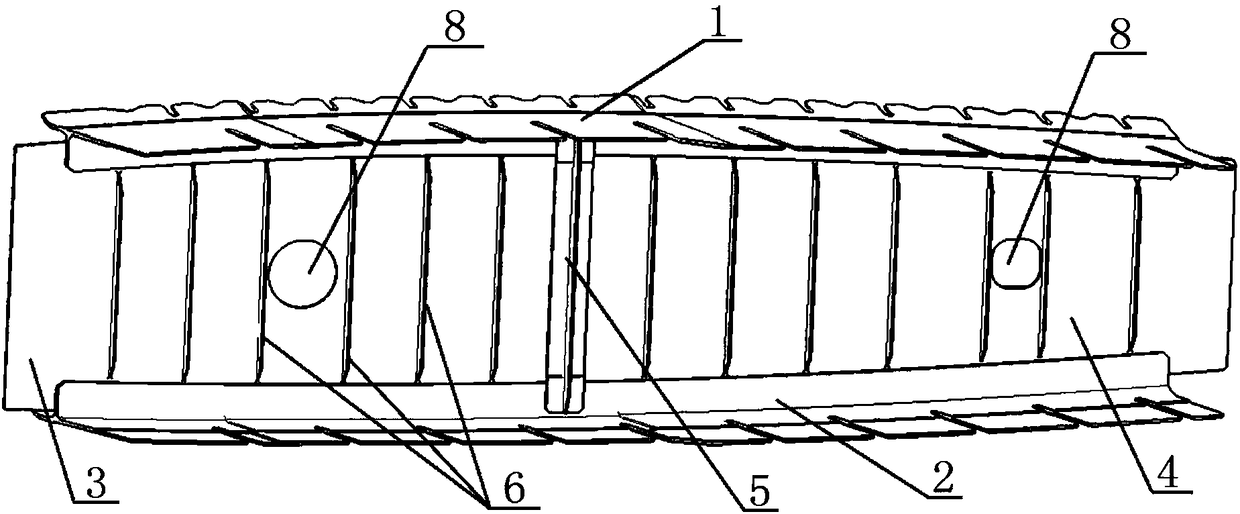

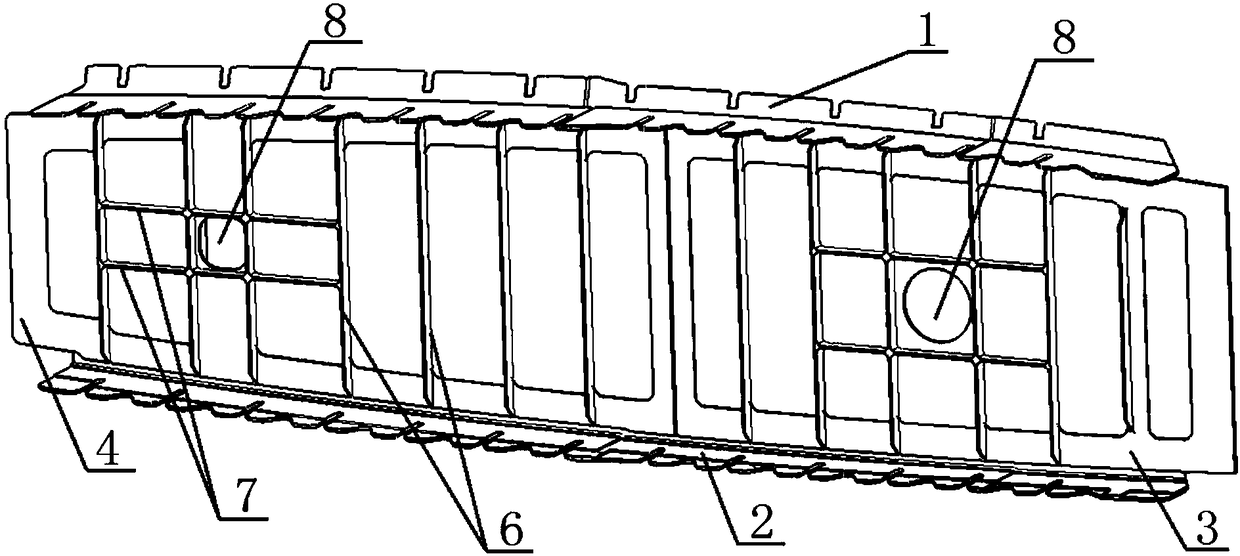

[0017] The invention provides a combination rib of an aircraft wing, such as figure 1 As shown, it includes upper edge strip 1, lower edge strip 2, front web 3, rear web 4 and butt angle material 5, upper edge strip 1, lower edge strip 2, front web 3, rear web 4 and butt joint The angle material 5 is preferably made of aluminum alloy machined parts;

[0018] The cross-section of the upper edge strip 1 and the lower edge strip 2 is T-shaped, and its thickness is preferably 3mm to 5mm. Both sides of the upper edge strip 1 and the lower edge strip 2 along the span of the aircraft are provided with gaps, which are used for wall panels. The long stringer is inserted during docking, the upper edge of the front web 3 and the upper edge of the rear web 4 are fixed to the lower edge of the upper edge bar 1 through fasteners, and the lower edge of the front web 3 and the lower edge of the rear web 4 are both passed through The fastener is fixed to the lower edge of the lower edge strip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com