Dust-absorbing electric grinding device for automobile maintenance

A technology for dust collection devices and automobiles, applied in grinding/polishing safety devices, grinding machines, portable grinding beds, etc., which can solve the problems of health hazards for operators, environmental pollution, inconvenient movement at any time, etc., to achieve convenient operation and cost saving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following is further described in detail through specific implementation methods:

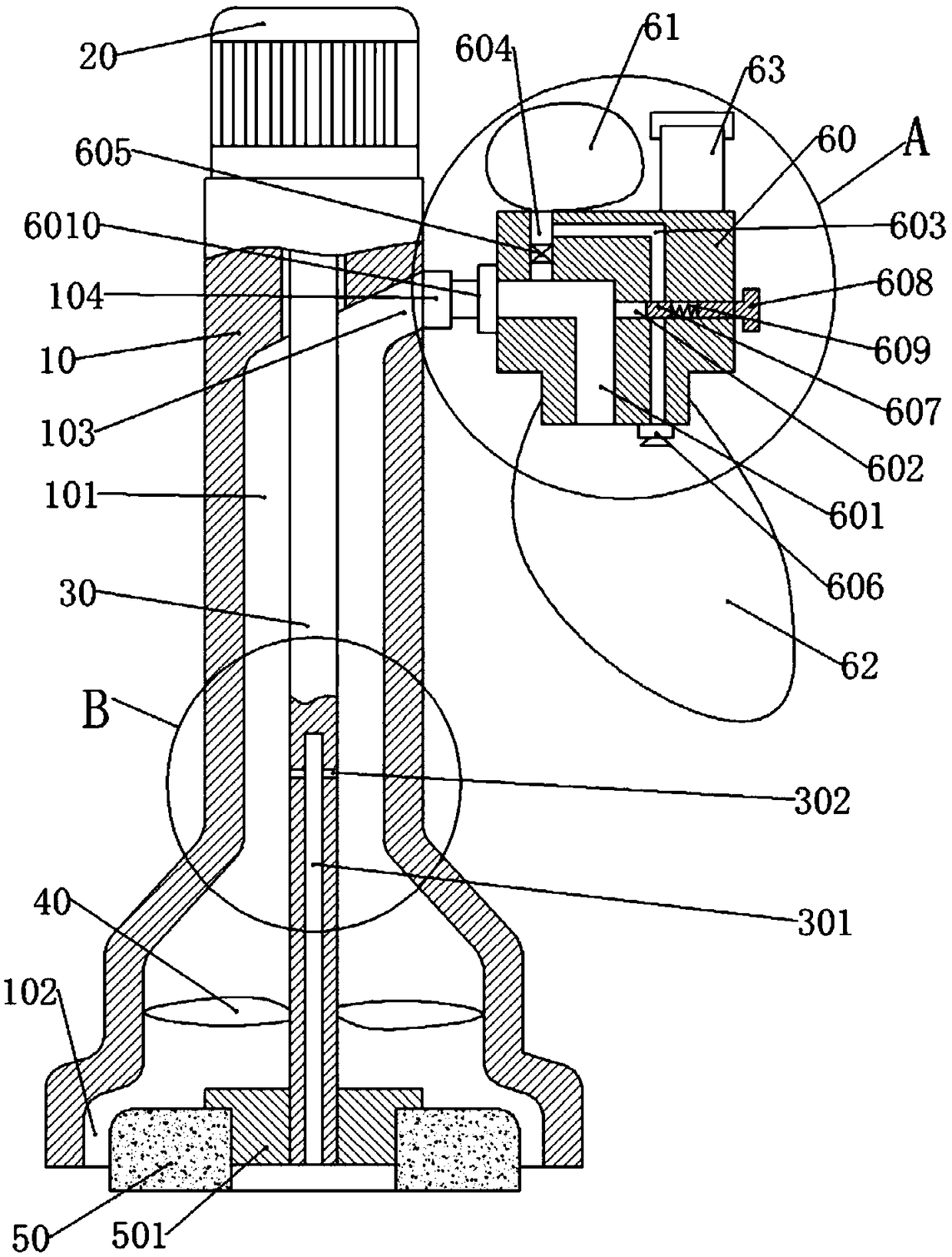

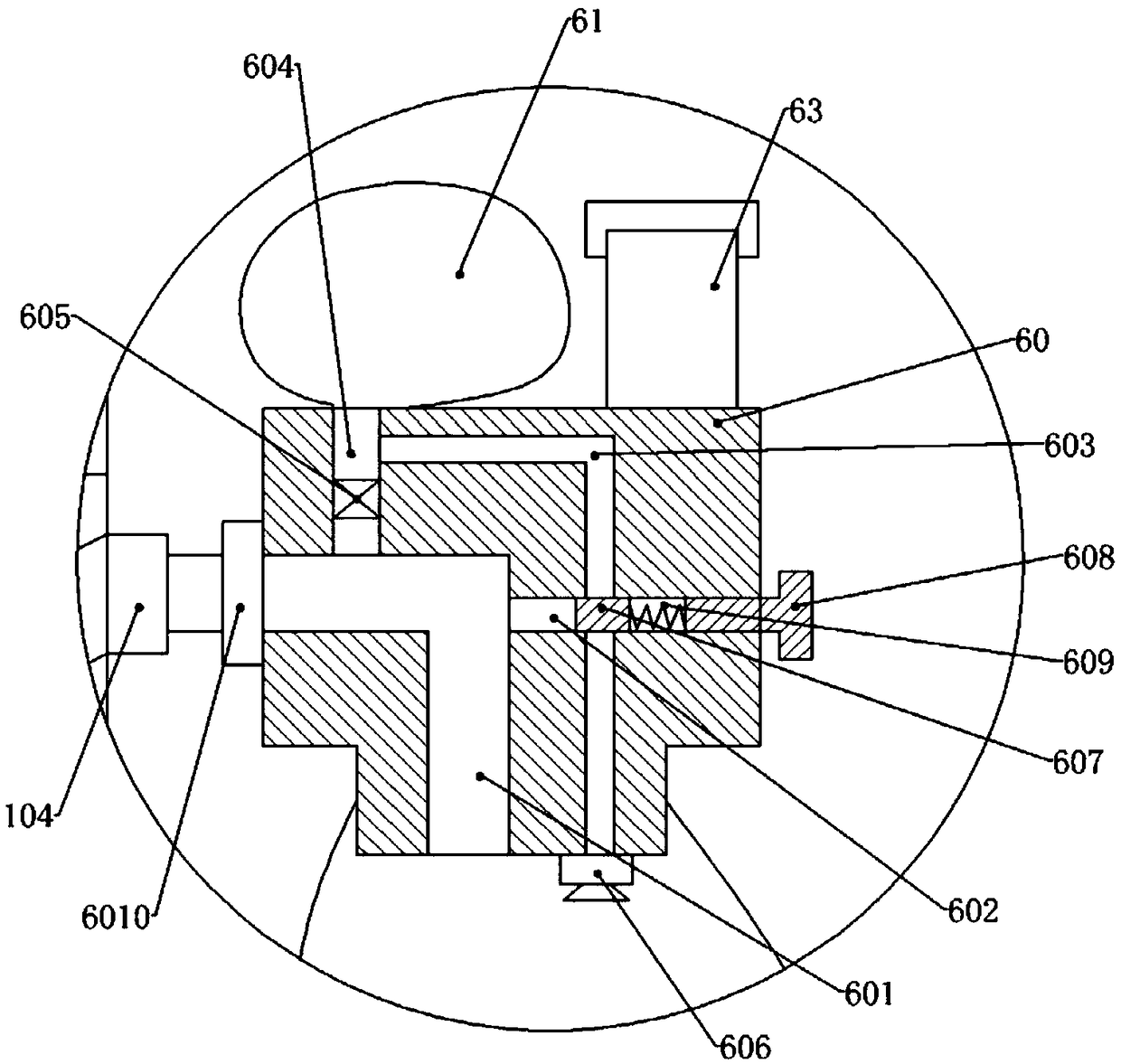

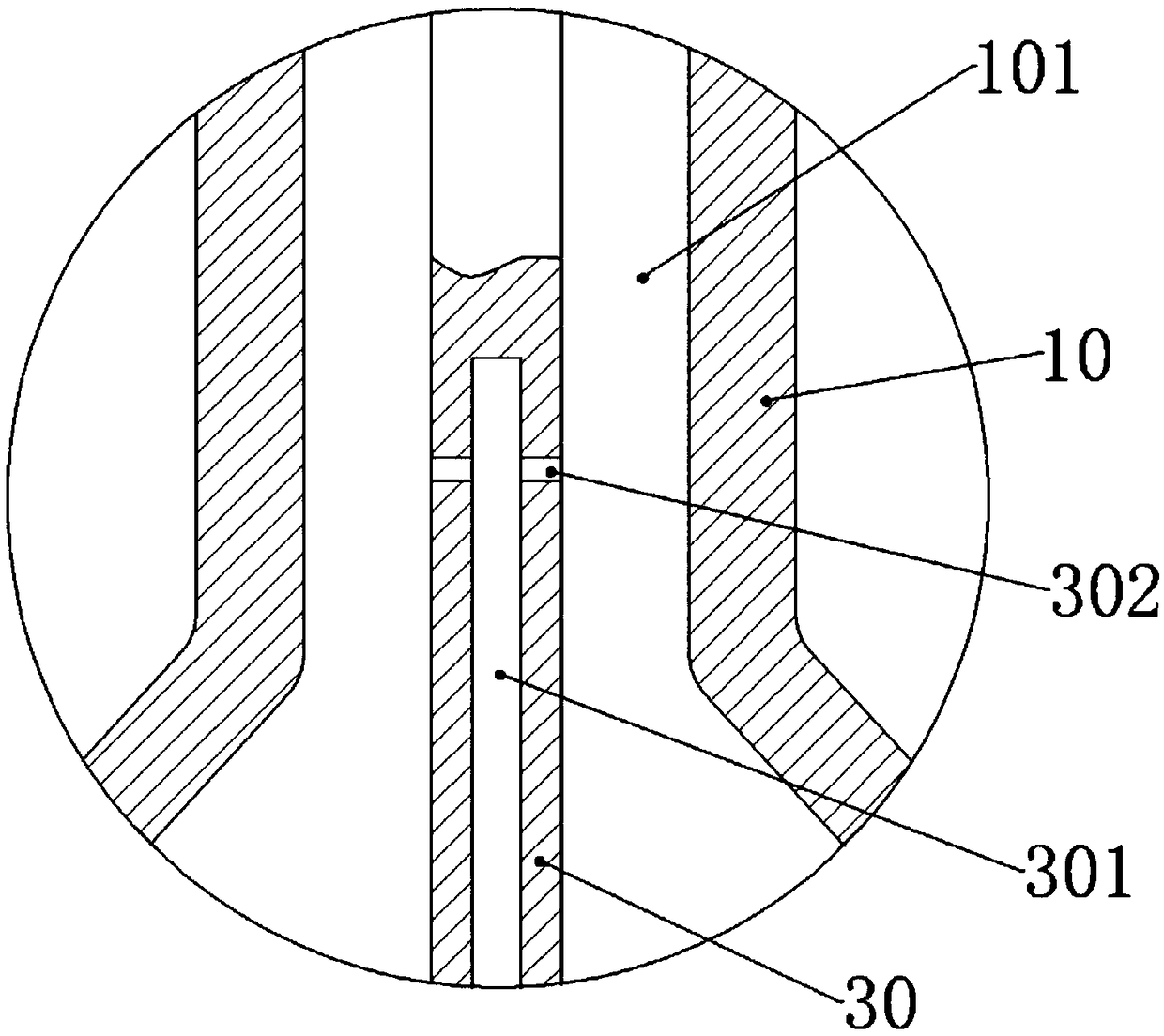

[0020] The reference signs in the drawings of the description include: housing 10, guide rail 20, detail 101, opening 102, air duct outlet 103, air outlet 104, motor 20, transmission shaft 30, blind hole 301, through hole 302, impeller 40 , polishing sheet 50, mounting seat 501, base 60, air bag 61, dust bag 62, water tank 63, air duct 1 601, slideway 602, air bag exhaust duct 603, air intake duct 604, intake check valve 605 , Sprayer 606, spool 607, adjustment rod 608, stage clip 609, air inlet nozzle 6010.

[0021] Examples are attached figure 1 , attached figure 2 , image 3 Shown:

[0022] The vacuum electric grinding device for automobile maintenance includes a housing 10, a motor 20, a transmission shaft 30, an impeller 40, a grinding plate 50 and a dust collecting device. The housing 10 is a hollow rotating body. In order to reduce the weight of the housing 10 The materi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap