sliding cam system

A sliding cam, cam technology, used in engine control, engine components, machine/engine, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

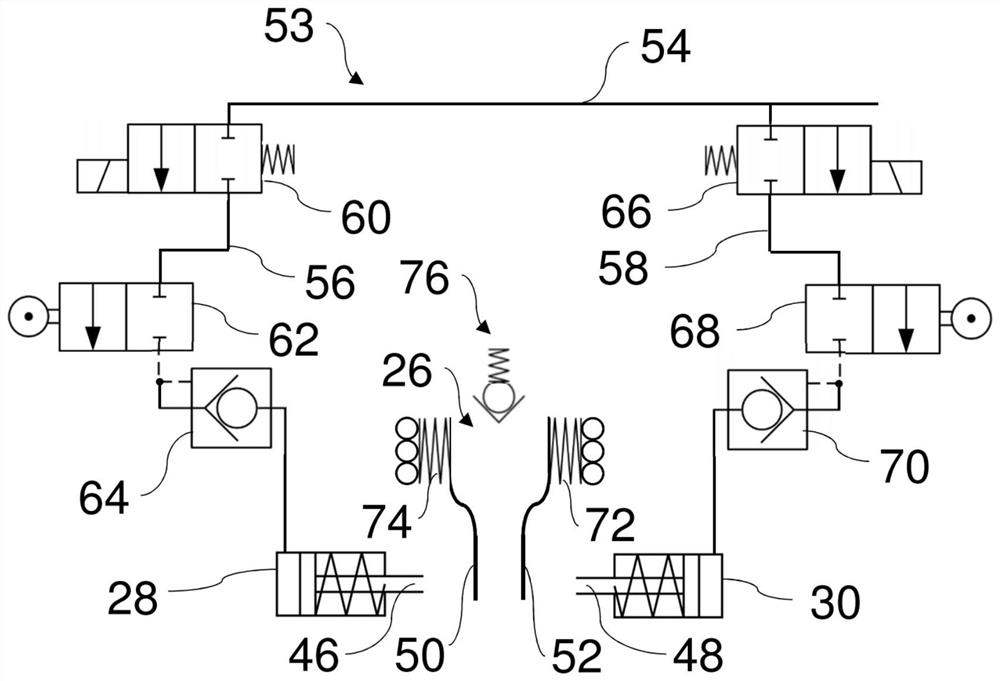

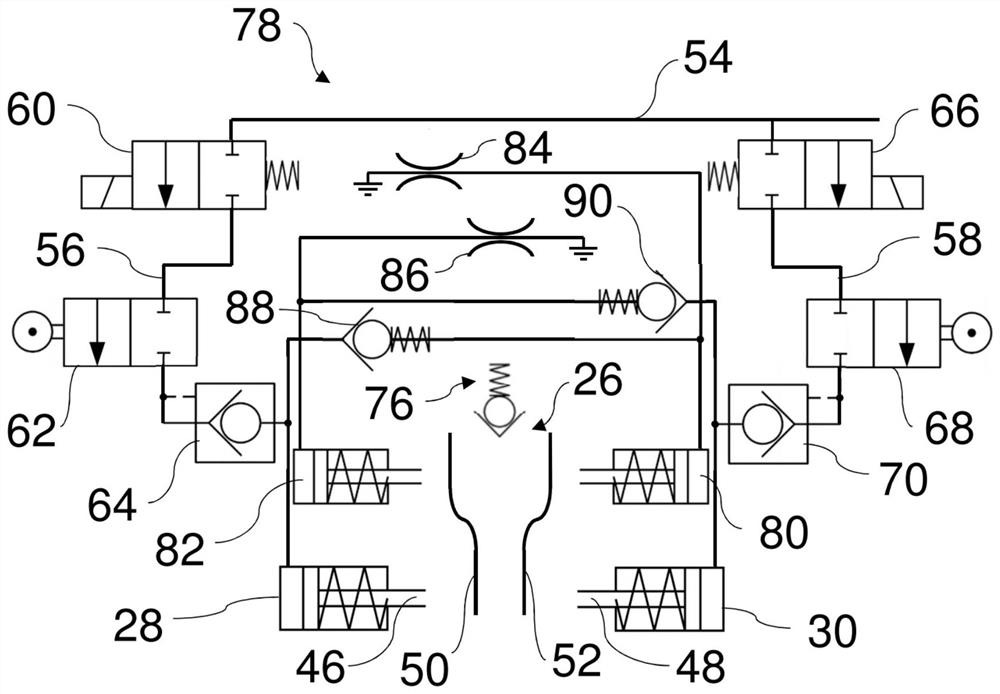

[0038] The exemplary embodiments shown in the figures are at least partially identical, such that similar or identical parts bear the same reference signs, and in order to avoid repetition they are also explained with reference to other exemplary embodiments or to the description of the figures.

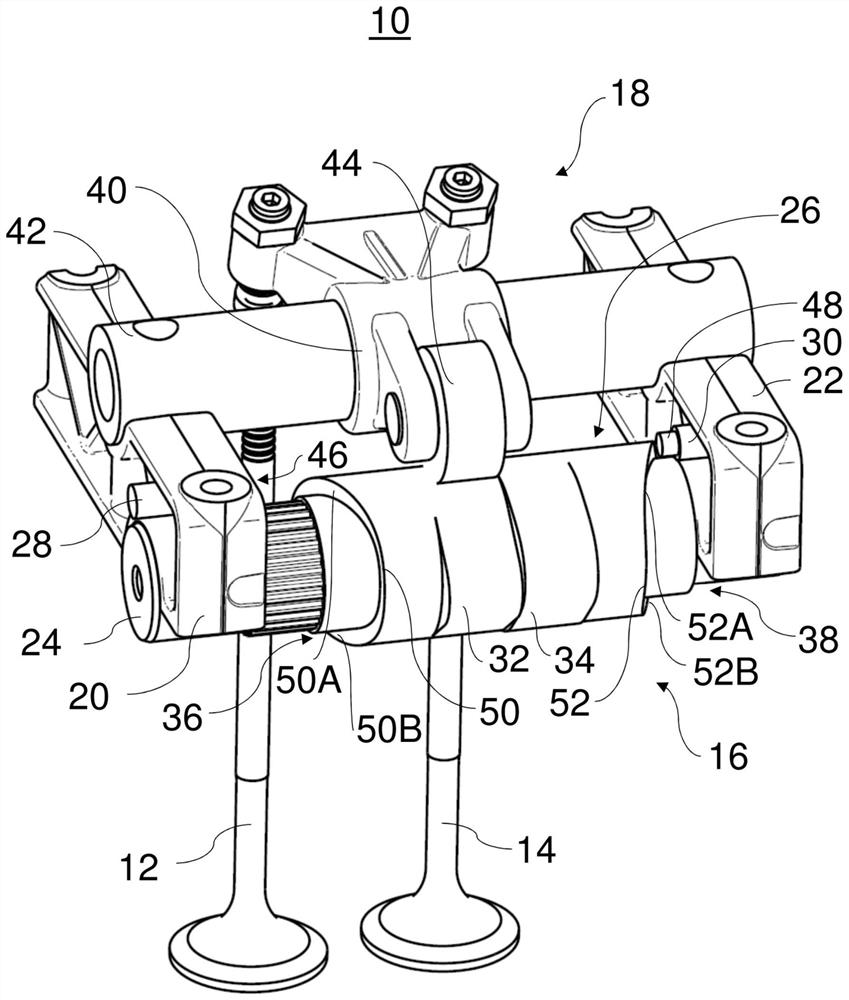

[0039] figure 1 A variable valve mechanism 10 is shown. For example, the variable valve train 10 may be part of an internal combustion engine of a commercial vehicle, in particular a truck or a bus. The variable valve mechanism 10 includes a first gas exchange valve 12 , a second gas exchange valve 14 , a sliding cam system 16 , a force transmission device 18 , a first bearing housing (bearing body) 20 and a second bearing housing (bearing body) 22 .

[0040] The variable valve mechanism 10 is used to regulate the control of the ventilation valves 12 , 14 . In particular, the opening times, closing times and / or valve lifts of the gas exchange valves 12 , 14 can be adjusted. The ga...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap