Bending-proof flat wire combination production method

A production method and flat wire technology, applied in the direction of circuit/collector parts, electrical components, circuits, etc., can solve the problems of affecting the transmission effect, easy to be bent, etc., to ensure stable use, strong practicability, and simple process. and ingenious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

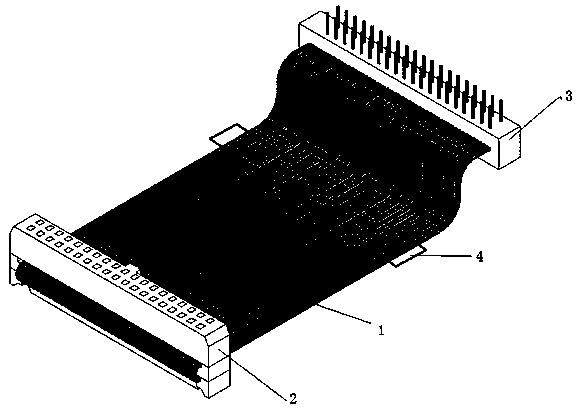

[0010] Such as figure 1 As shown, the production method of the bending-resistant flat wire assembly includes the following steps: (1) Cut 20 wires 1 with a length of 120mm according to the requirements; (2) Press one end of the wire 1 into the plug 2 with a wire crimping pliers And install the plug protective cap; (3) Use crimping pliers to press the other end of the wire 1 into the plug socket 3 to form a flat wire assembly; (4) Install a chuck 4 in the middle of the flat wire assembly.

[0011] The production method of the present invention has a simple and ingenious process. By setting the chuck, it can prevent the protection combination from being damaged by bending when it is accidentally bent during the installation process, thereby ensuring long-term stable use in the future. It has strong practicability and is worth popularizing.

[0012] The above is only the specific implementation of the invention, but the scope of protection of the invention is not limited thereto,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com