Motor test tool and use method thereof

A technology of motor testing and tooling, which is applied in the testing of machines/structural components, measuring devices, static/dynamic balance testing, etc. It can solve problems such as accelerated bearing wear, shortened mechanical life, vibration, etc., and achieves the effect of ensuring stable use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

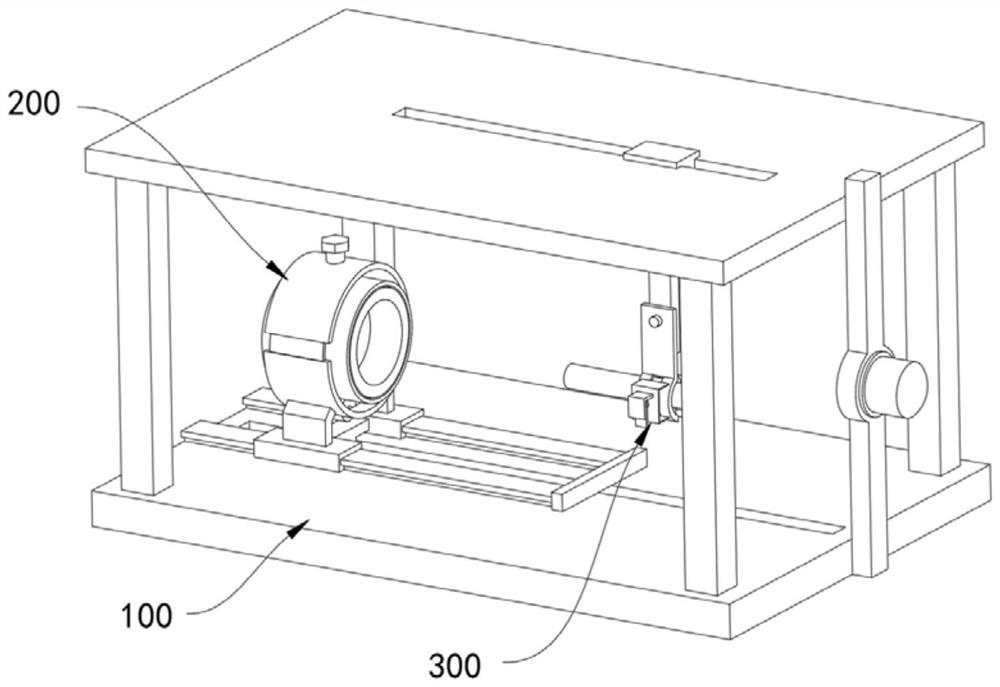

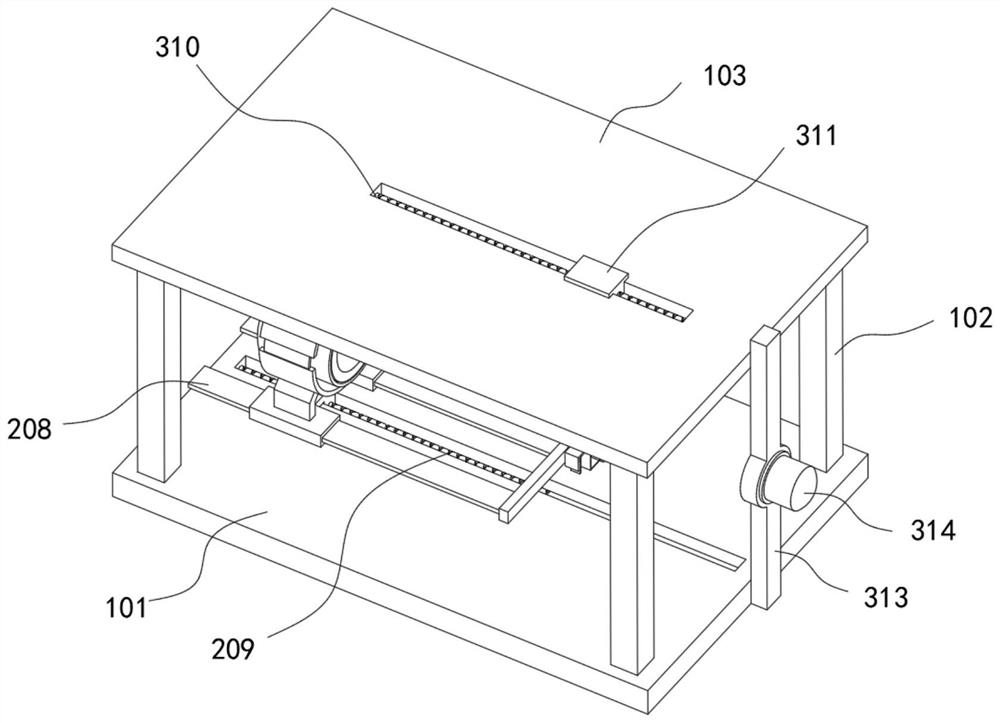

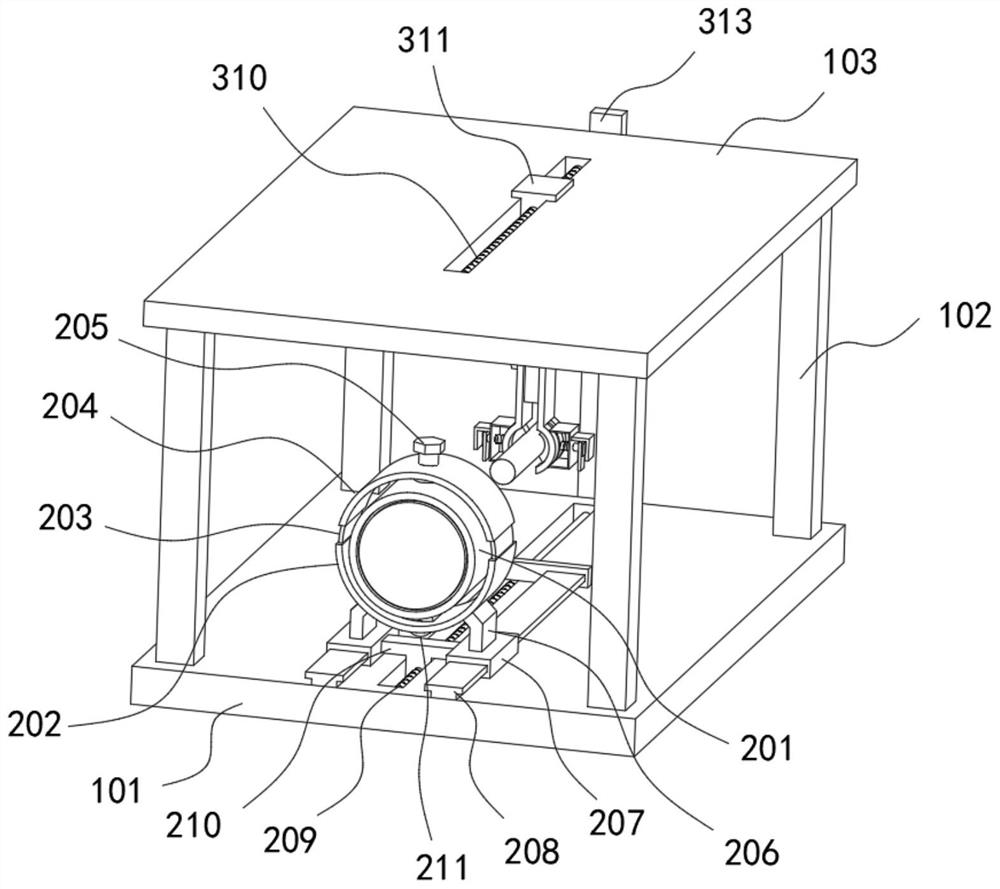

[0030] refer to Figure 1-5 , a motor testing tool, comprising: a support structure 100, including a support base plate 101 and a plurality of support columns 102 evenly connected to the upper end of the support base plate 101, the upper ends of the plurality of support columns 102 are fixedly connected with a same horizontal support top plate 103 .

[0031] The casing structure 200 includes a motor casing 201 , and a limit unit connected to the outer side of the motor casing 201 is provided. The upper end of the bottom plate 202 is slidably connected with two movable plates 203, and the upper ends of the two movable plates 203 are fixedly connected with the same arc-shaped top plate 204, and the upper end of the arc-shaped top plate 204 is threadedly connected with a vertical fastening screw 205, and The lower end of the tightening screw 205 is fixedly connected with a limit block which is in contact with the motor housing 201 .

[0032] Further, the upper end of the suppor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com