Scrubber air duct and sewage tank integrated structure

A waste water tank and washing machine technology, which is applied in the integrated structure of the washing machine's air duct and sewage tank, can solve the problems of poor positioning reliability, increased body weight, and fan damage, and achieves the effect of convenient cleaning and stable use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

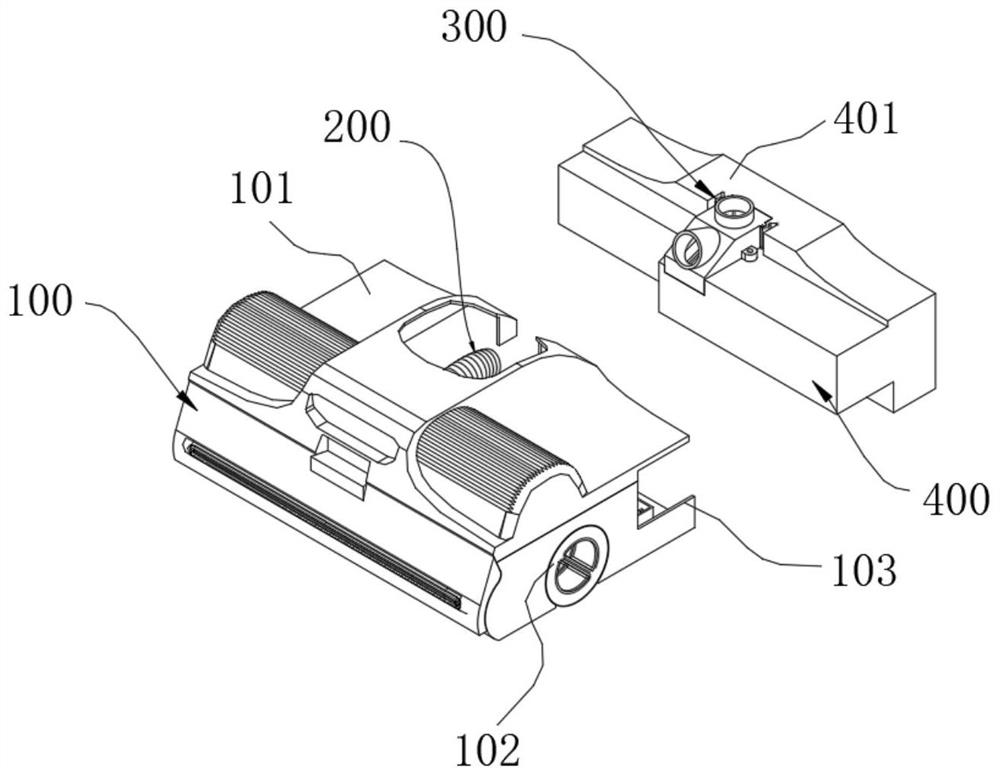

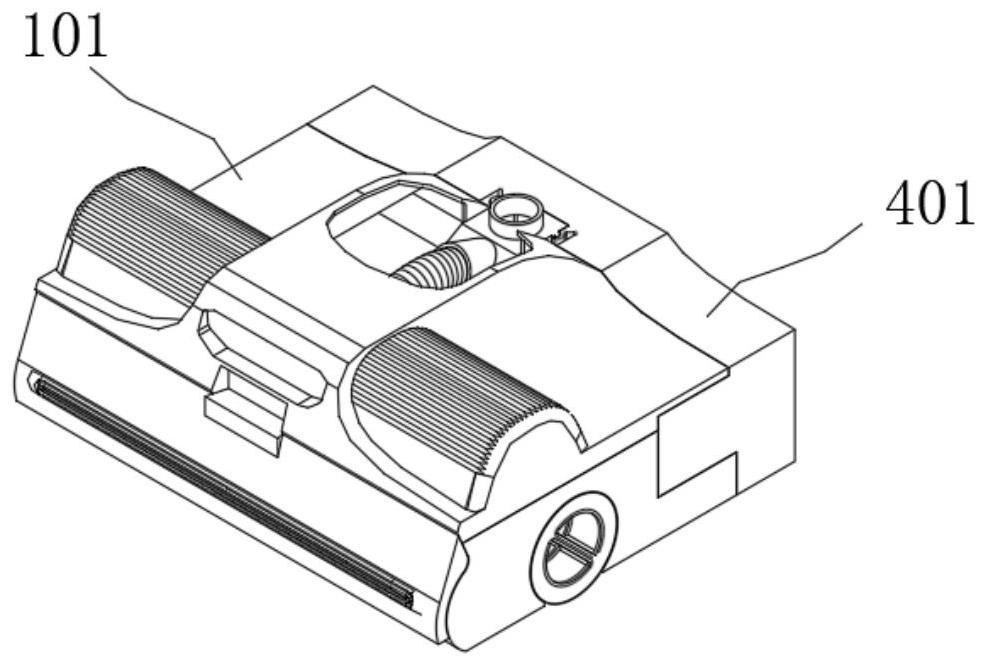

[0030] refer to Figure 1-7 , which is the first embodiment of the present invention, provides an integrated structure of the air duct and sewage tank of the scrubber, including: the scrubber assembly 100, the suction assembly 200, the air duct assembly 300 and the sewage tank assembly 400, the scrubber The machine assembly 100 includes an upper cover 101 , a washing machine body 102 and a chassis 103 , the upper cover 101 is correspondingly connected to the upper side of the washing machine body 102 , and the chassis 103 is correspondingly connected to the lower end of the washing machine body 102 .

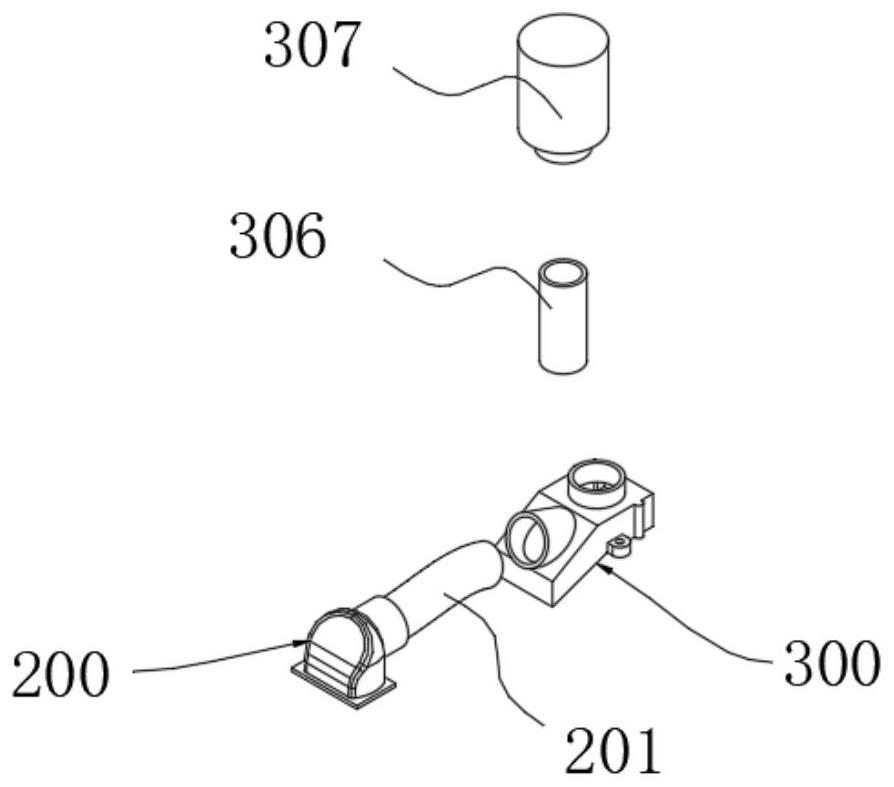

[0031] Wherein, the air suction assembly 200 includes a first air suction duct 201 connected to the washing machine body 102. Specifically, the side wall of the first air suction duct is connected with a mounting seat communicating with it, and the outer wall of the mounting seat is provided with The mounting plate is fixedly connected with the external ground brush by bolts, wh...

Embodiment 2

[0038] refer to Figure 1-7 , which is the second embodiment of the present invention. This embodiment is different from the first embodiment in that: the upper cover 101 is connected to the upper end of the washing machine body 102 by buckling, and the chassis 103 is fixedly connected to the washing machine body 102 by a plurality of bolts. The lower end of the floor washing machine body 102 is provided with a rolling brush inside the floor washing machine body 102, and the lower end of the rolling brush extends to the lower side of the chassis 103 and contacts the ground.

[0039] Compared with Embodiment 1, further, the side wall of the sewage tank body 401 away from the housing 402 is provided with a sewage outlet communicating with the inside thereof, and the outside of the sewage tank body 401 is threadedly connected with a side cover corresponding to the sewage outlet.

[0040] All the other structures are identical to those of Example 1.

[0041] During use, the chass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com