Manufacturing method of vehicle seat bracket outer plate

A car seat and anti-deformation technology, which is applied to vehicle seats, seat suspension devices, special positions of vehicles, etc., can solve problems such as weak seat brackets, car seat tilting, unreasonable design, etc., and achieve improved Strong and stable performance, buffer pressure and impact force, increase the effect of firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

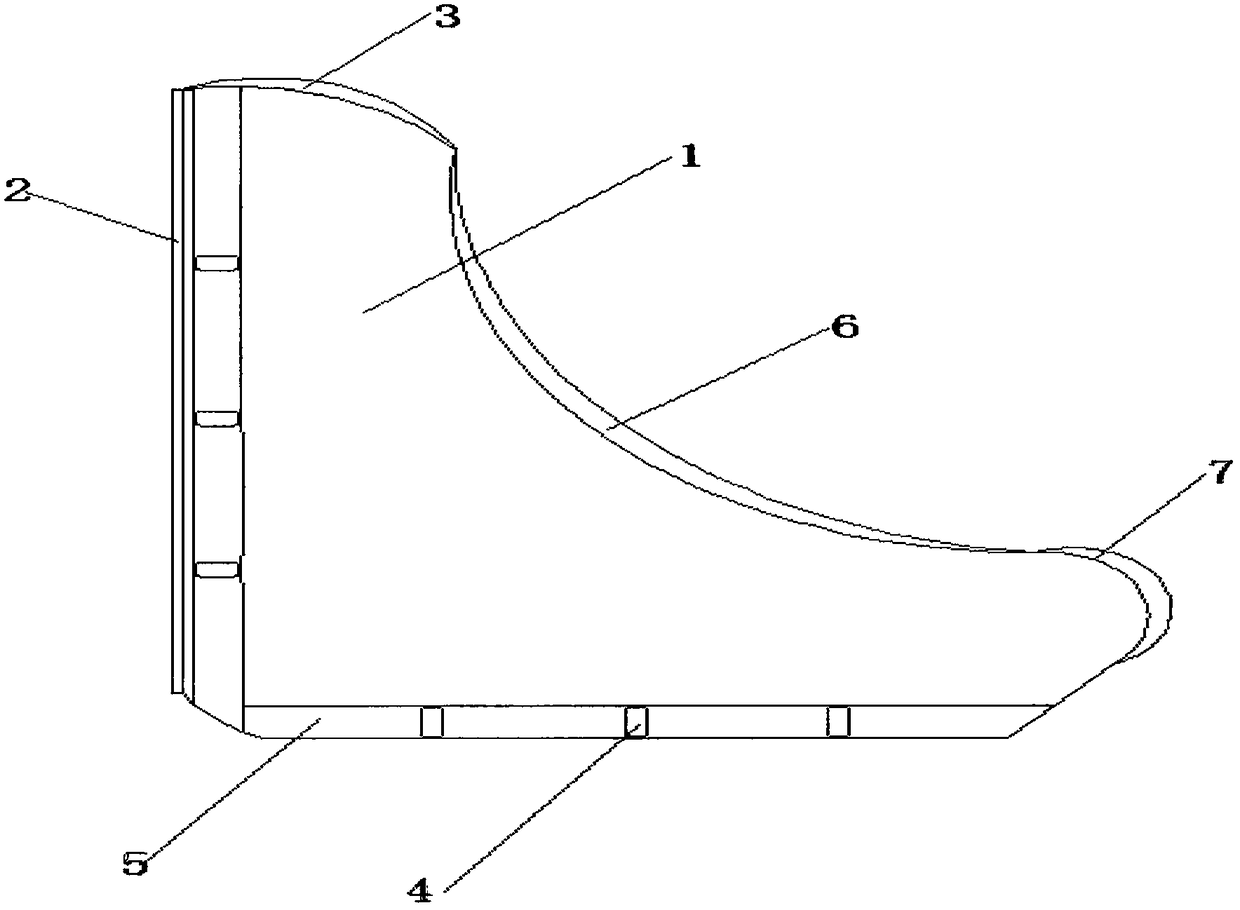

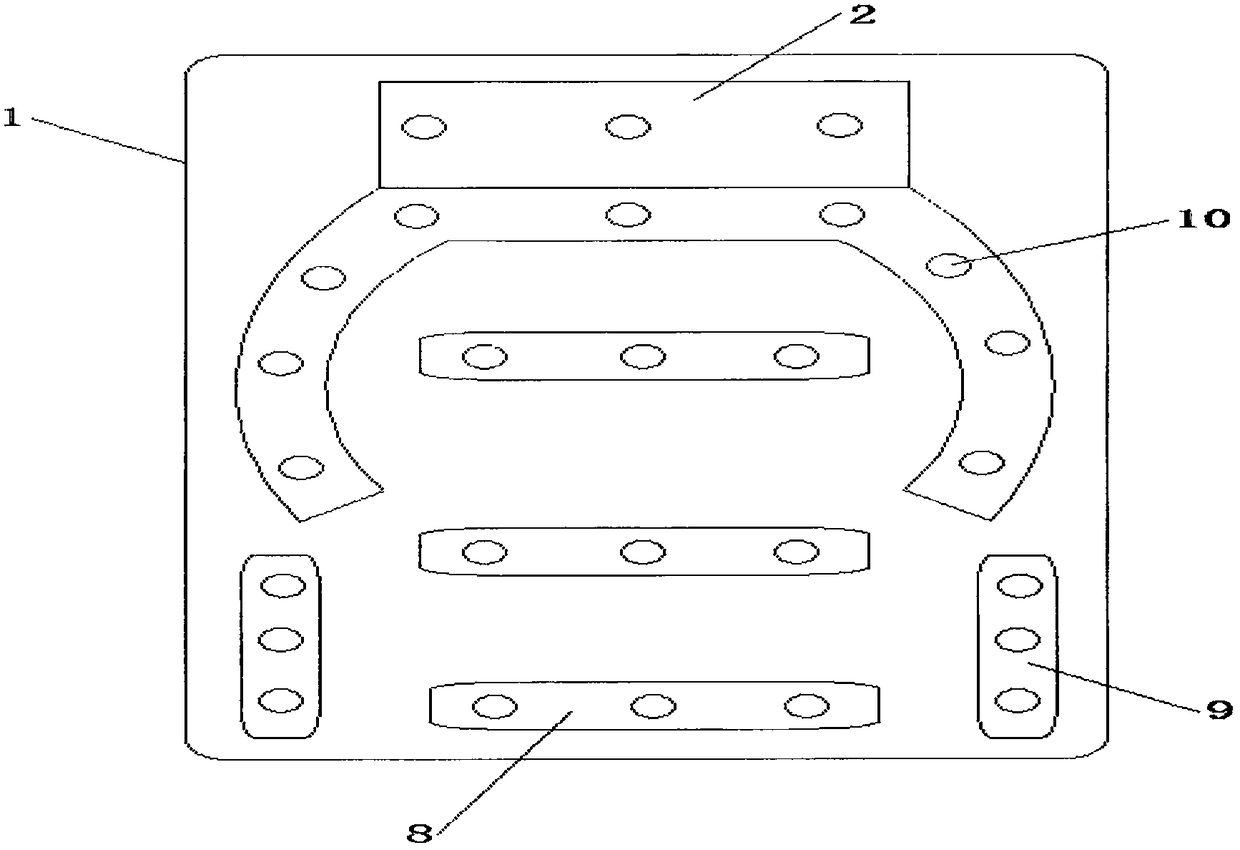

[0015] An automobile seat bracket outer panel, comprising a bracket outer panel main body (1), an anti-deformation workpiece (2), an anti-deformation strip I (8), an anti-deformation strip II (9), a fixing screw hole (10), a shock-absorbing Space capsule (5), shock absorbing spring (4), buffer shock absorbing pad I (3), buffer shock absorbing pad II (6), buffer shock absorbing pad III (7), the main body of the outer plate of the bracket (1) is left The side is provided with anti-deformation workpiece (2), anti-deformation strip I (8), anti-deformation strip II (9), and the anti-deformation workpiece (2), anti-deformation strip I (8), anti-deformation strip II (9) Both are provided with fixing screw holes (10), the middle of the anti-deformation workpiece (2) is provided with an anti-deformation strip I (8), and the lower surface of the anti-deformation workpiece (2) is provided with an anti-deformation strip II (9); The front surface and the lower surface of the bracket outer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com