Vibration damping device

A technology for anti-vibration devices and mounting components, applied in the direction of shock absorbers, shock absorber-spring combinations, springs/shock absorbers, etc., can solve problems such as abnormal sounds, achieve suppression of abnormal sounds, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

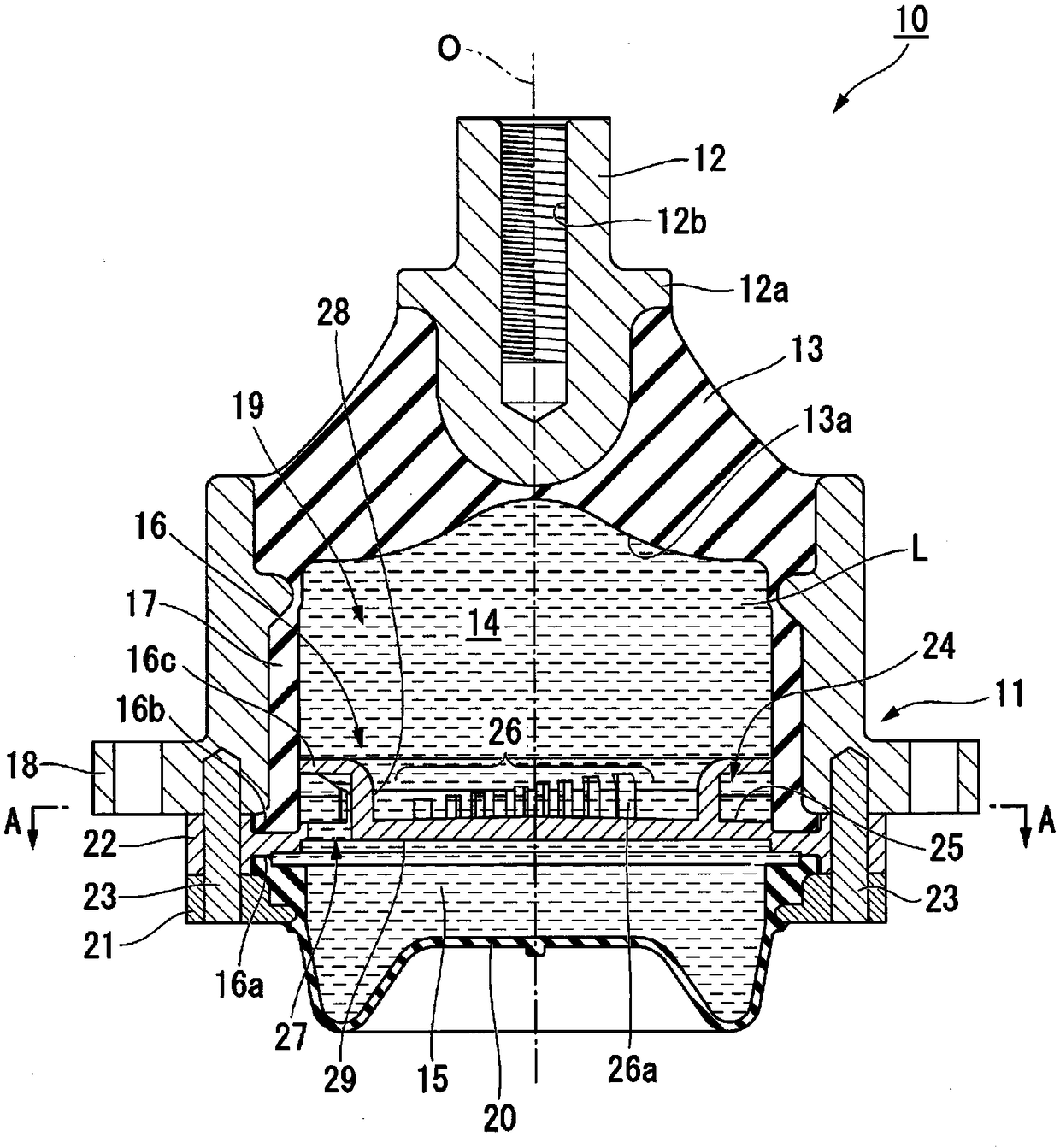

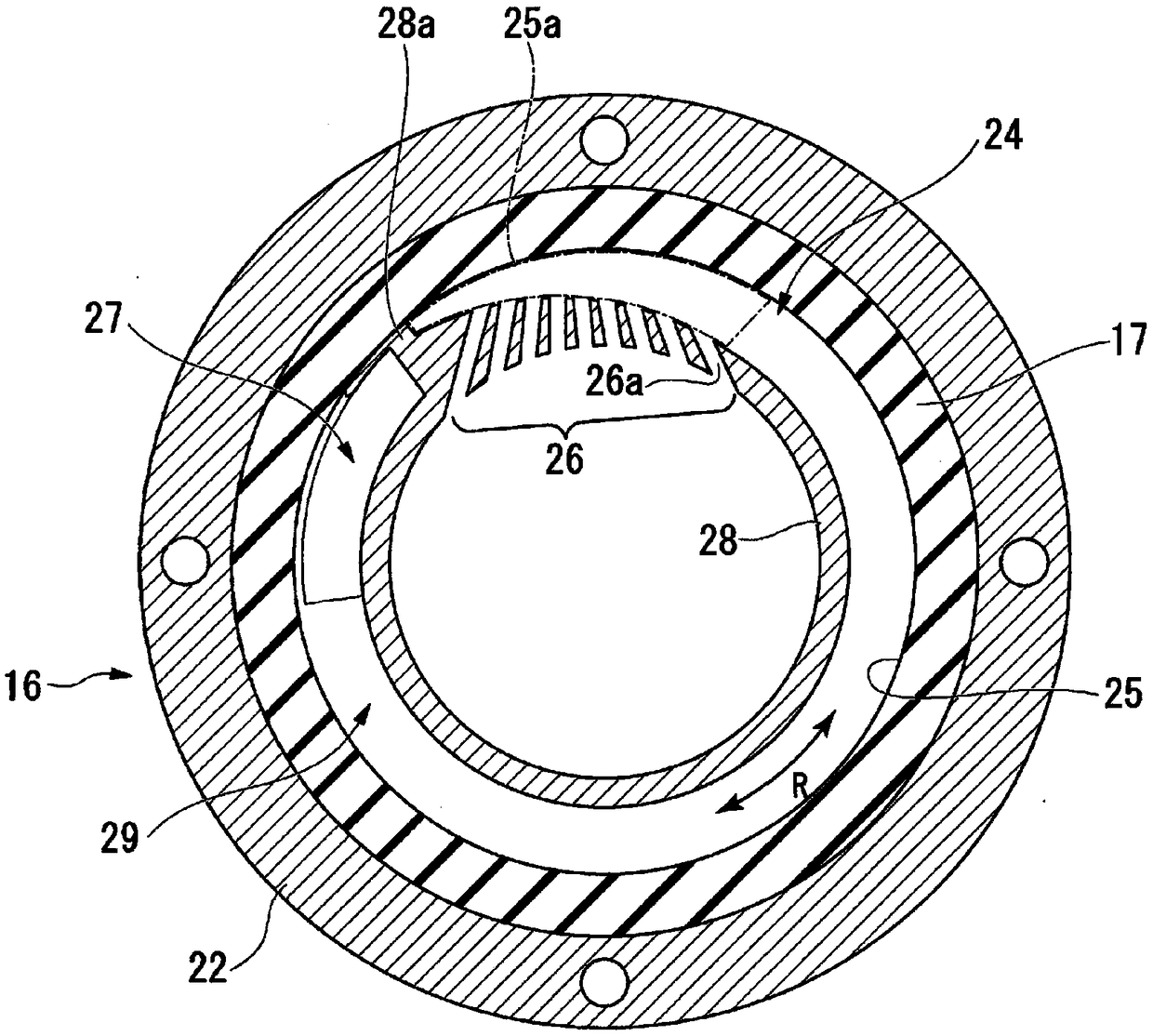

[0018] Below, based on figure 1 with figure 2 , the embodiment of the anti-vibration device of the present invention will be described.

[0019] Such as figure 1 As shown, the anti-vibration device 10 is a liquid-enclosed anti-vibration device, which includes: a first mounting member 11, which is cylindrical and connected to any one of the vibration generating part and the vibration receiving part; the second mounting member 12 , which is connected to the other of the vibration generating part and the vibration receiving part; the elastic body 13, which is used to elastically connect the above-mentioned first mounting member 11 and the second mounting member 12 to each other; and a partition member 16, which It is used to divide the inside of the first mounting member 11 into a main liquid chamber 14 and a secondary liquid chamber 15 which will be described later.

[0020] Hereinafter, the central axis of the first mounting member 11 is referred to as the axis O, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com