Small multilayer pay-off device

A pay-off, small technology, used in the transportation of filamentous materials, thin material handling, transportation and packaging, etc., can solve problems such as large volume, low space utilization, and bulkiness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

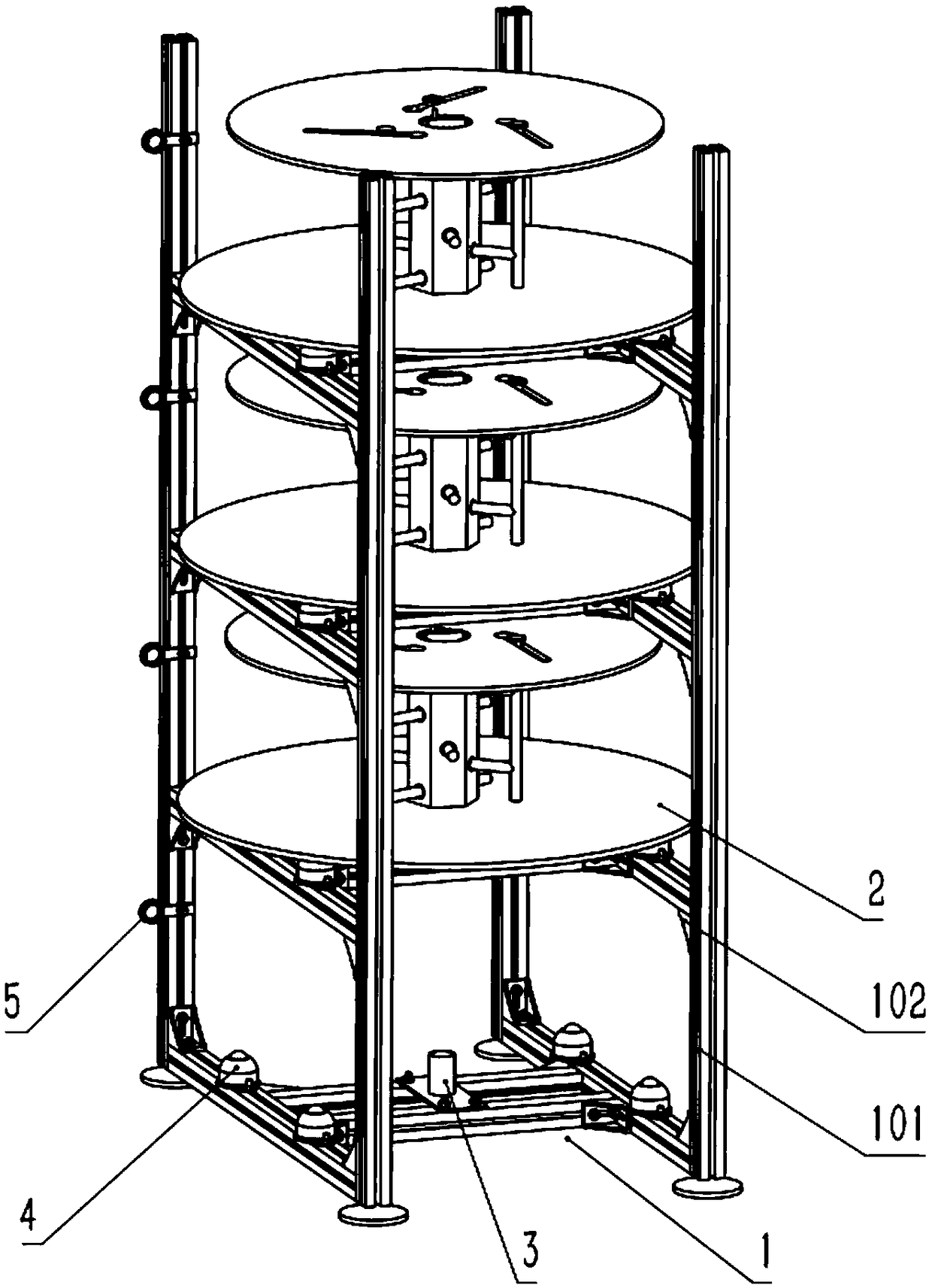

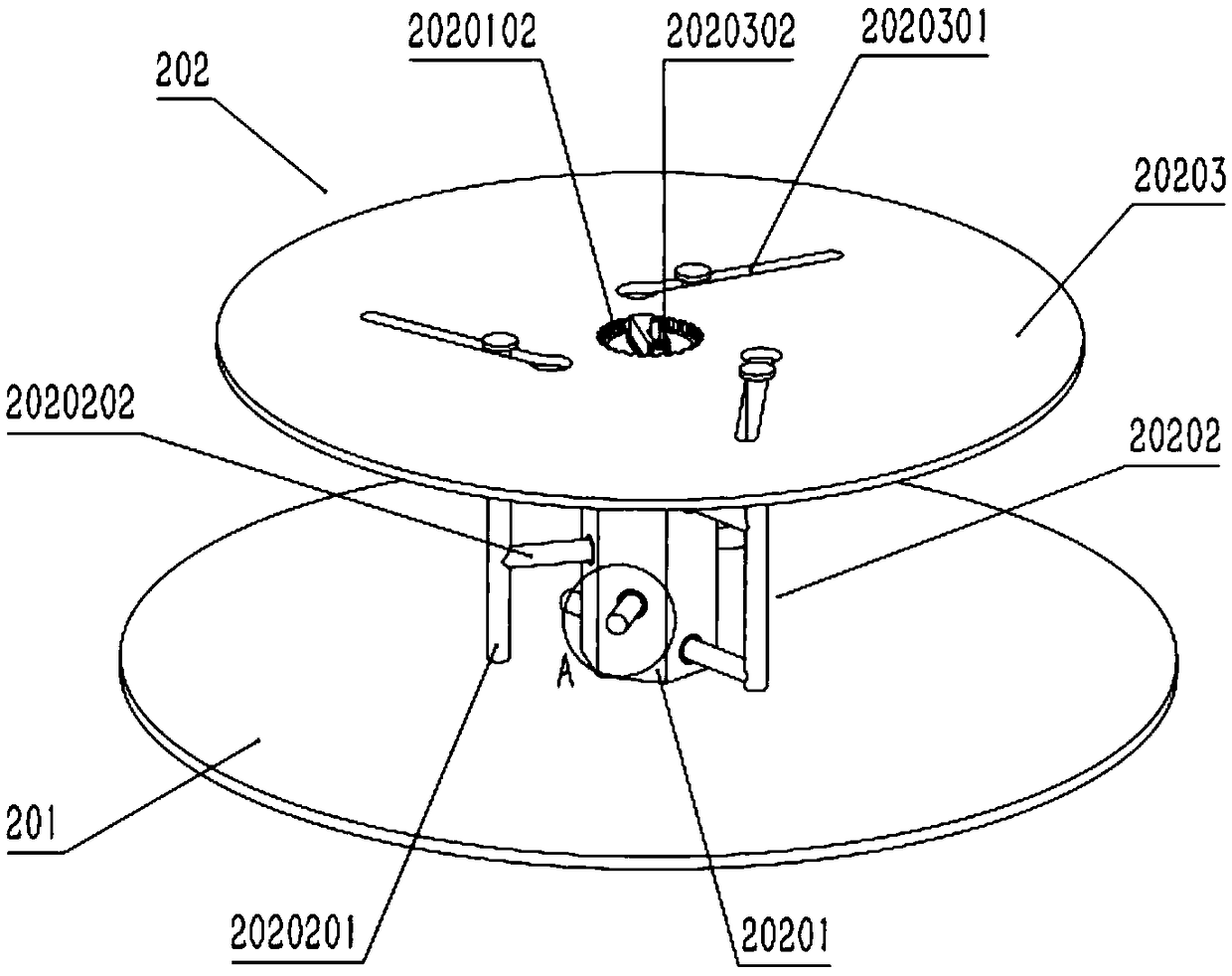

[0022] A small multi-layer wire pay-off, which is composed of a structural frame 1 and a wire tray 2. The structural frame 1 is equipped with a central rotating shaft 3 and a universal wheel 4, and is provided with a lead opening 5; the structural frame 1 includes metal profiles 101 and a rigid connecting body 102, the metal profile 101 is mechanically connected through the rigid connecting body 102 to form the structural frame 1 of the pay-off device; the tray 3 includes a tray bottom plate 201 and an adjustable limit 202, and the tray bottom plate 201 and the central shaft 3 Rotational connection; the adjustable limiter 202 is fixed on the tray bottom plate 201, and the adjustable limiter 202 can adjust the limit shaft diameter according to the inner diameter of the wire coil, and drives the wire coil to rotate with the tray bottom plate 201.

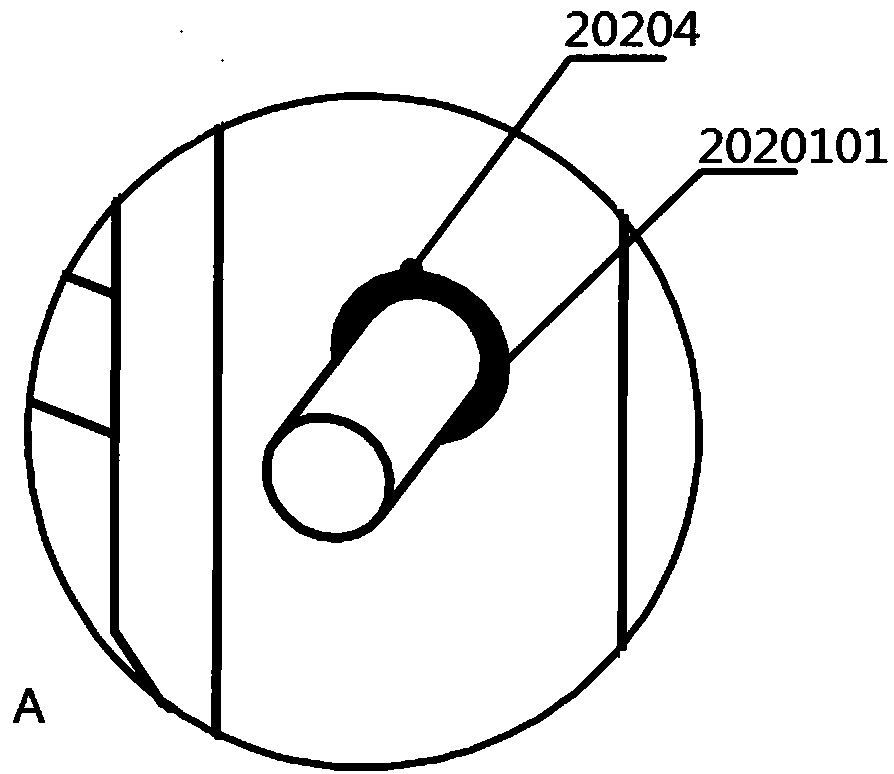

[0023] Further, the adjustable limit 202 includes a fixed support 20201, a limit rod 20202 and an upper cover 20203, the fixed suppor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com