Combined coupler

A coupler and combined technology, which is applied in the field of couplers, can solve the problems of single shape and simple structure of couplers, and achieve the effects of flexible and tight contact, convenient line management and layout, and avoiding waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

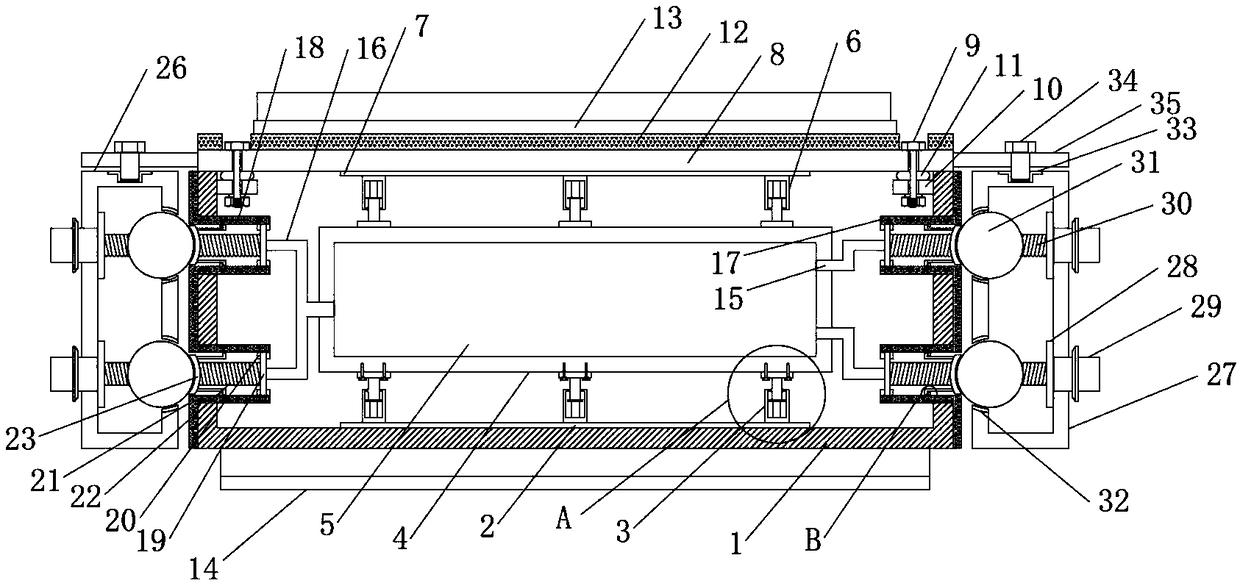

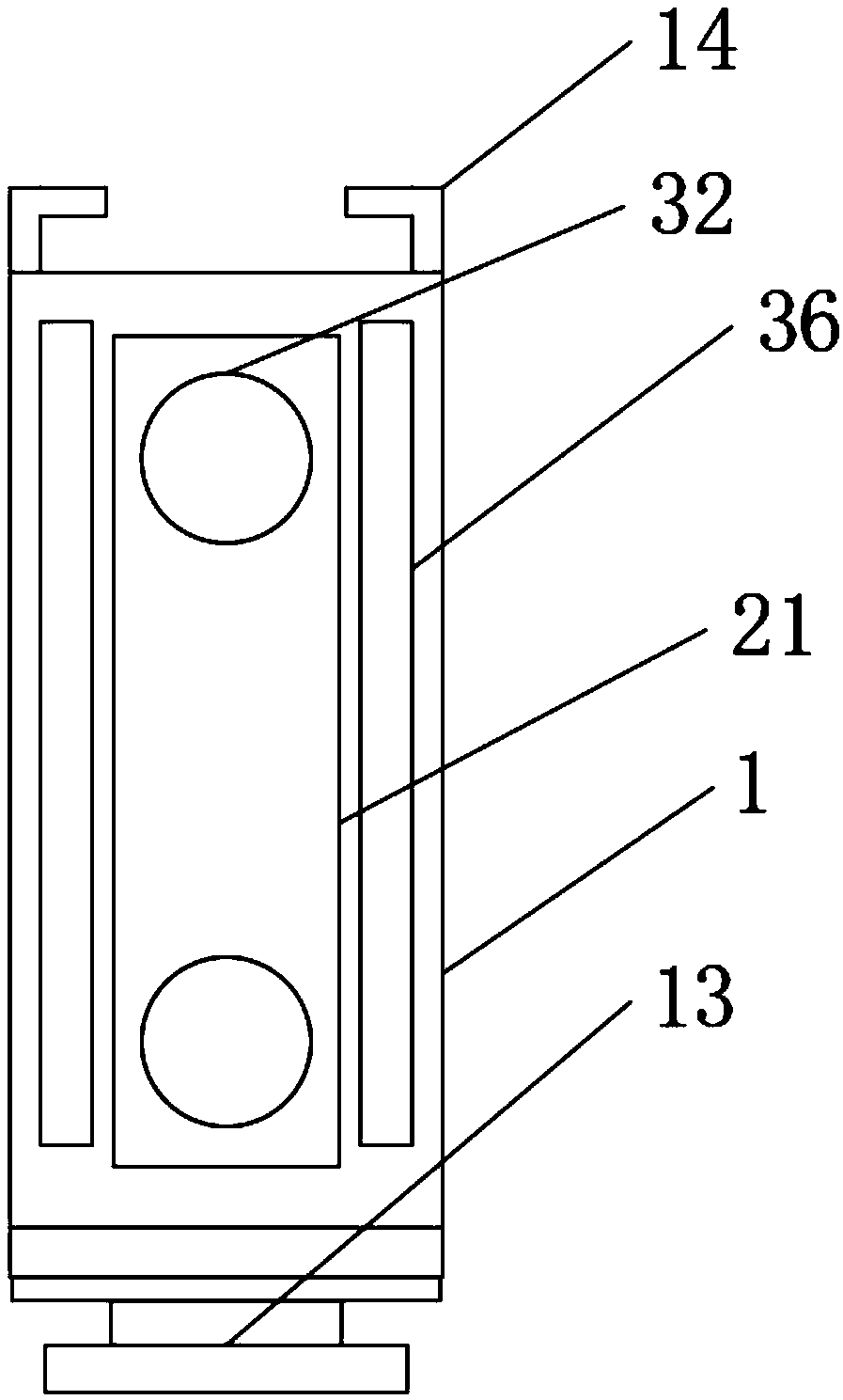

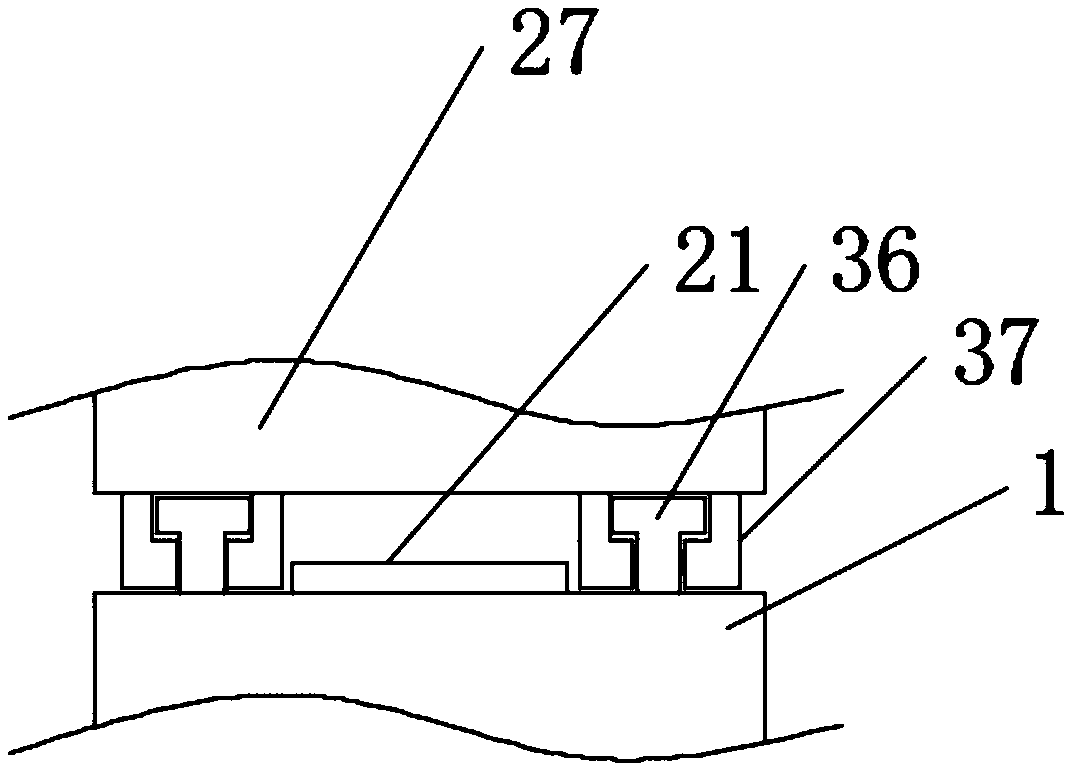

[0022] Such as Figure 1-5 As shown, this specific embodiment adopts the following technical solutions: a combined coupler, including a main body shell 1, a No. The shock mechanism connecting plate 2 is connected with the coupler housing 4 through a number of No. 1 shock absorbing mechanisms 3, and the No. 1 shock absorbing mechanism 3 includes a shock absorbing spring groove 38, a shock absorbing spring 39, a spring connecting plate 40, and a shock absorbing strut 41 and the pressure plate 42, the shock absorbing spring groove 38 is fixed on the side panel of No. The shock spring 39 is connected with a shock-absorbing strut 41 through a spring connecting plate 40, and one end of the shock-absorbing strut 41 away from the spring connecting plate 40 passes through a shock-absorbing spring groove 38 and is connected with a pressure plate 42. The No. 1 shock-absorbing mechanism 3 The inner pressure plate 42 is connected to the coupler housing 4 through several shock absorbing me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com