Plastic stool injection mold base for preventing reinforcing ribs from dragging damage during demolding

A technology for injection molding and plastic stools, which can be applied to home appliances, other home appliances, and household components. It can solve the problems of unstable stool support, stool thickness reduction, and insufficient draft angle of injection molds, etc., to achieve flexible adjustment of inclination , optimize stability, and improve the effect of insufficient product protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

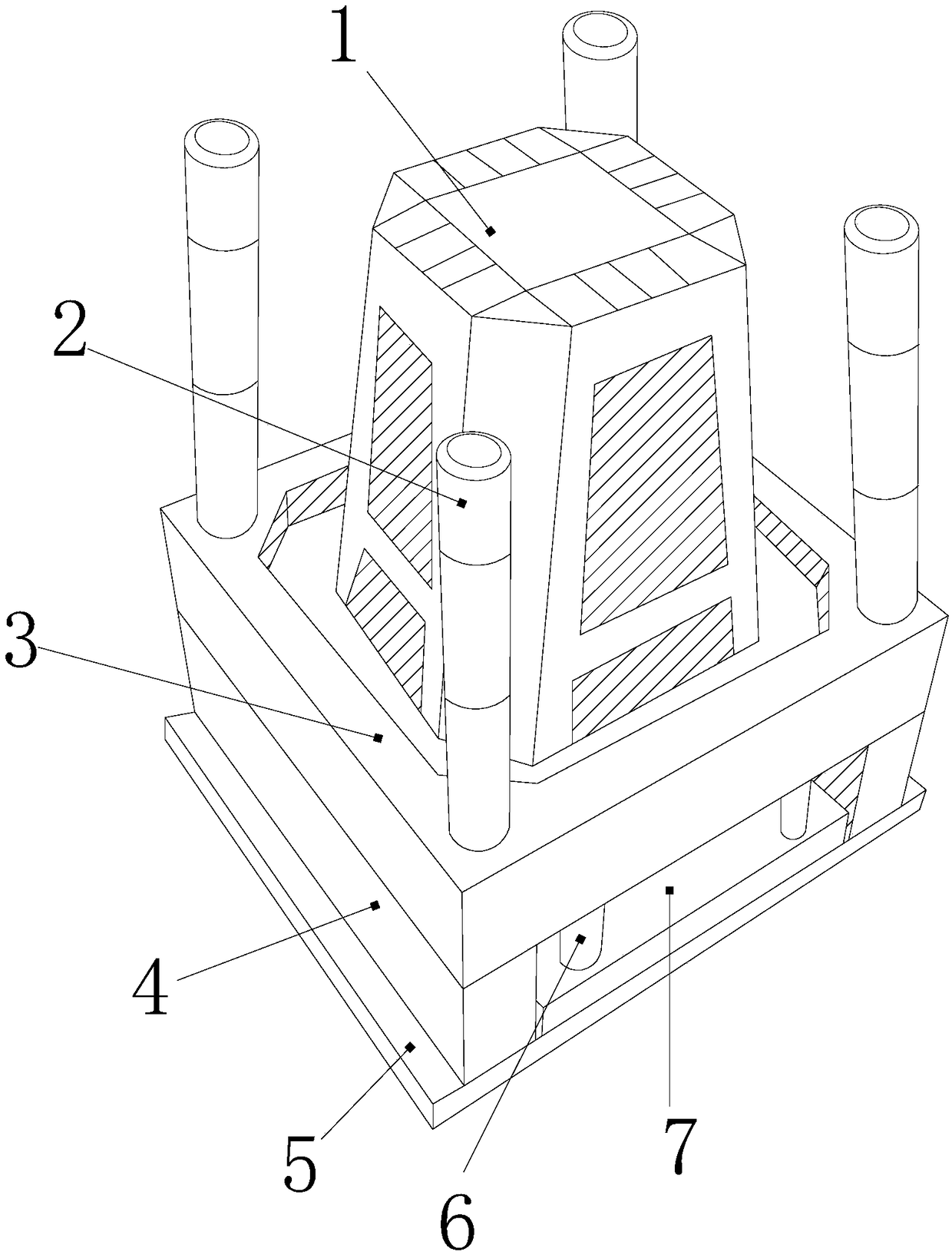

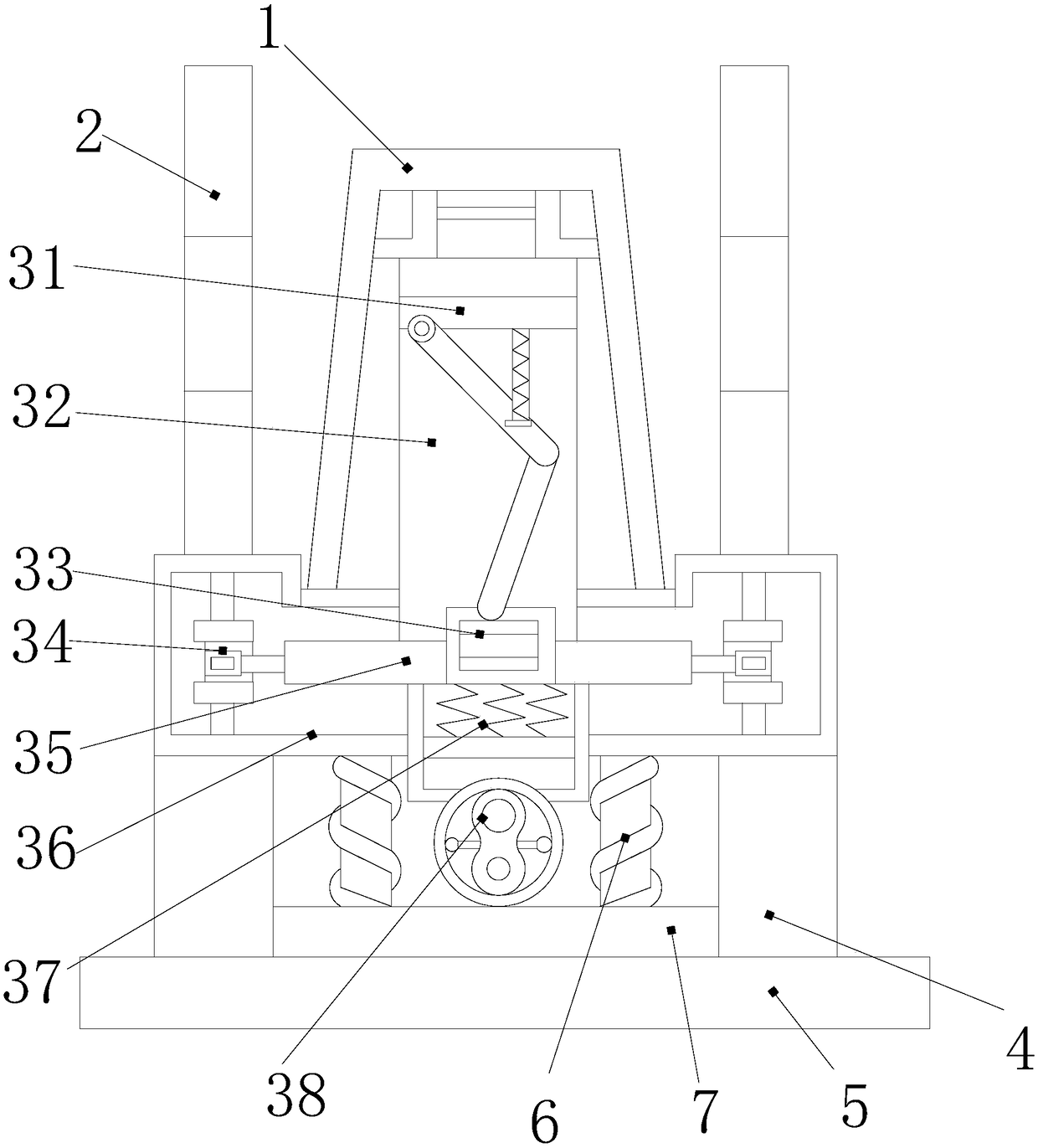

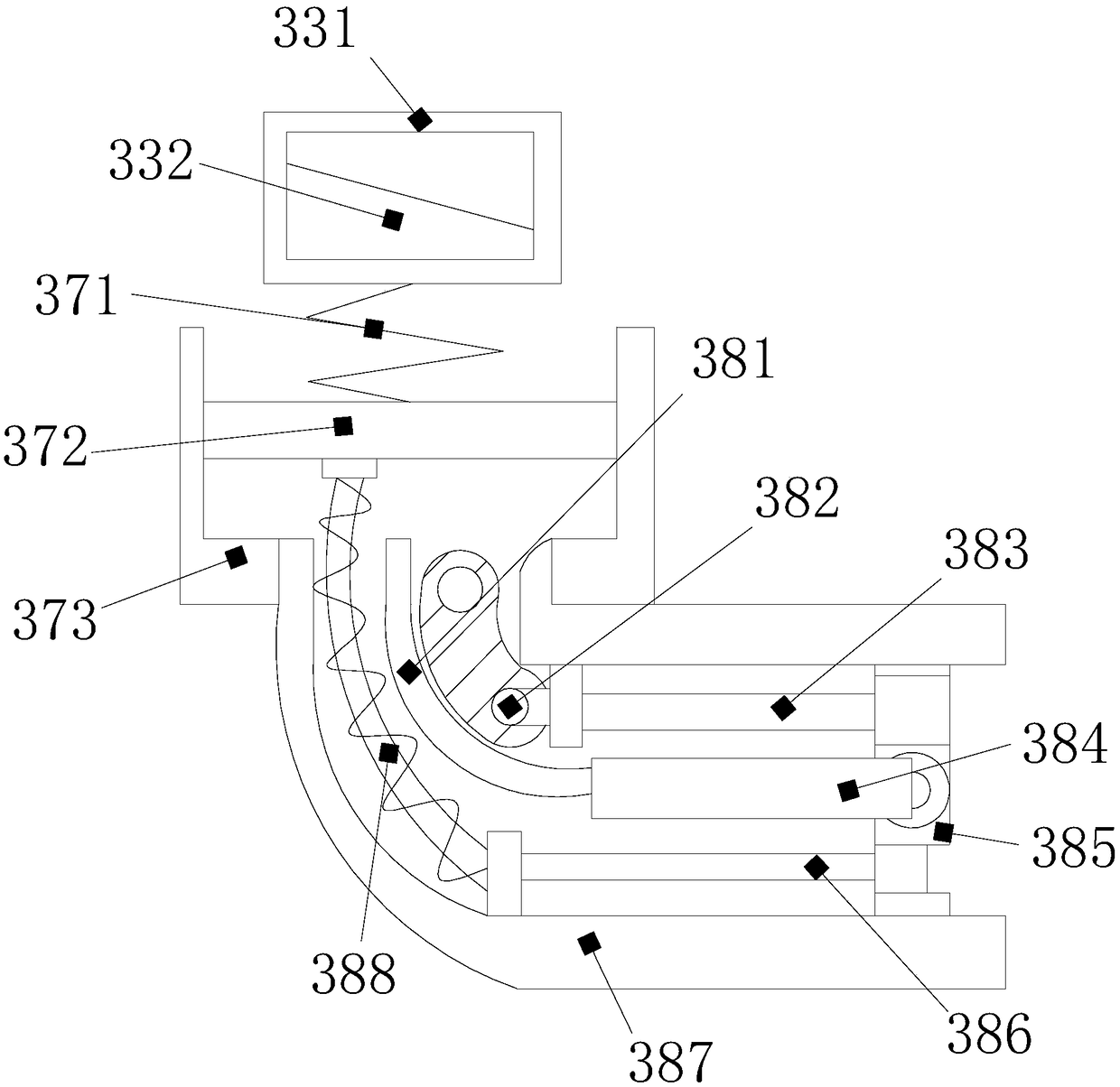

[0027] see Figure 1-Figure 5, the present invention provides a plastic stool injection molding mold base based on anti-reinforcing ribs, the structure includes: mold shell plate 1, pin column 2, cylinder ejector 3, base pad 4, Base 5, torsion spring column 6, liner 7, the base block 4 is provided with two and respectively close to the left and right lower corners of the cylinder ejector 3, the torsion spring column 6 is provided with two and respectively Inserted in the left and right upper corners of the liner 7, the bottom surface of the liner 7 is close to the top surface of the base 5 and is on the same level, the base block 4 and the base 5 are welded into one, the latch There are four columns 2 and they are respectively inserted and embedd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com