Traction ball joint with adjustable torsional stiffness, and torsional stiffness regulating method

A technology of torsional stiffness and adjustment method, which is applied in the field of rail transit, can solve problems such as differences in stiffness adjustment methods, and achieve the effects of large axial stiffness and torsional stiffness, large deflection angle, and small radial stiffness and deflection stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

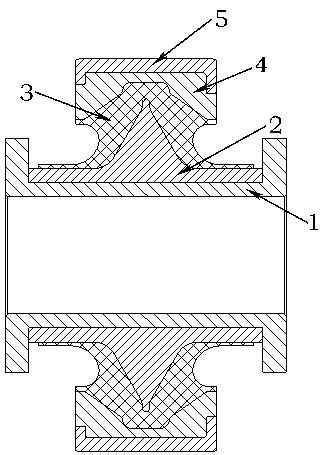

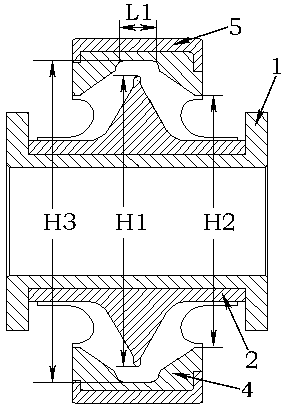

[0027] The traction ball joint is a rotating body, and the section of the traction ball joint is as follows: figure 1 As shown, the traction ball joint includes a first inner sleeve 1 , a second inner sleeve 2 , a rubber body 3 , a first outer sleeve 4 and a second outer sleeve 5 . The cross-section of the first inner sleeve 1 is T-shaped, and the cross-section formed by the assembly of two T-shaped first inner sleeves 1 is figure 1 The "工" font in. The two ends of the first inner sleeve 1 are bent to form a groove, and the second inner sleeve 2 is embedded in the groove of the first inner sleeve 1, so that the first inner sleeve 1 can prevent the second inner sleeve 2 from Axial direction movement.

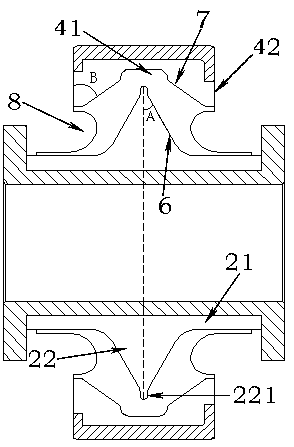

[0028] The second inner sleeve 2 includes a bottom plate 21 and an inner sleeve main body 22, and the bottom plate 21 and the inner sleeve main body 22 are seamlessly connected as a whole. The bottom plate 21 is in the shape of a tube, the cross section of the inner sleeve bod...

Embodiment 2

[0036] The difference between this embodiment and the first embodiment is that no raised boss 221 is provided on the top of the inner sleeve main body 22 , and only the top of the inner sleeve main body 22 is made into a circular arc surface. Therefore, the value of the thinnest vertical fork thickness in this embodiment refers to half of the difference between the maximum length of the top arc surface of the inner sleeve main body 22 and the length of the minimum inner diameter outside the first outer sleeve 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com