Assembly type linear plate spring for refrigeration compressor

A refrigeration compressor and assembled technology, which is applied in springs, low internal friction springs, springs/shock absorbers, etc., can solve the problems of complex design and expression of the closed-end profile, large concentrated stress, and difficult machining. Achieve the effect of small local stress, uniform stress distribution, and meet the requirements of linear stiffness load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

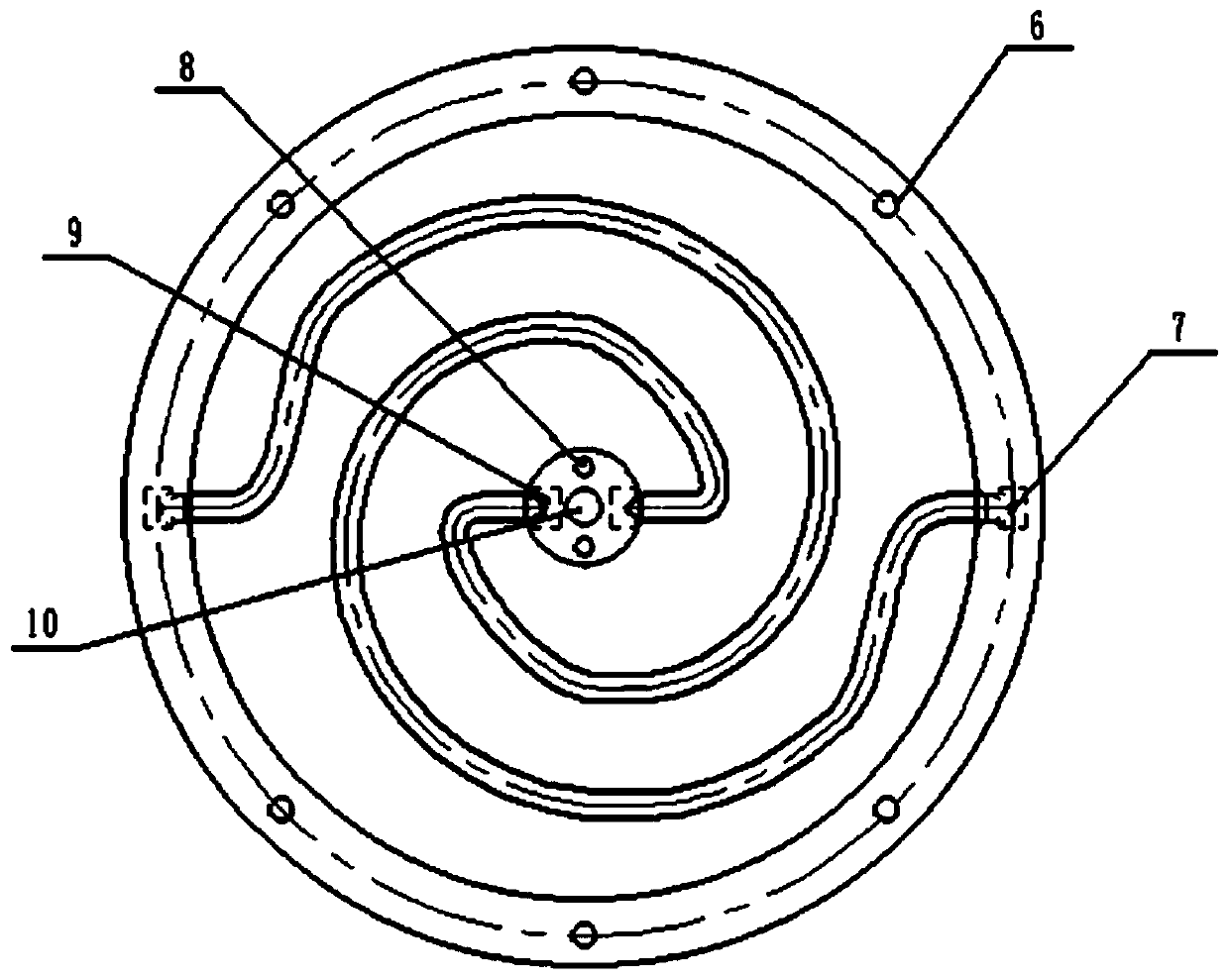

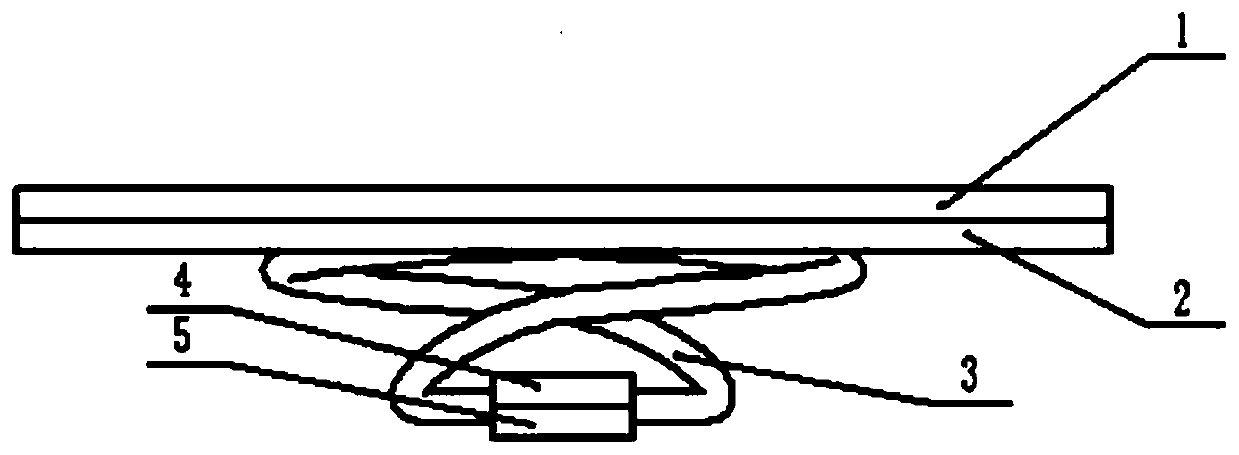

[0053] Such as Figure 1 to Figure 9 As shown, the leaf spring in this example includes two axially symmetrical cylindrical spring arms 3 with the same structure, outer fixing washers 1, 2 and inner fixing washers 4, 5.

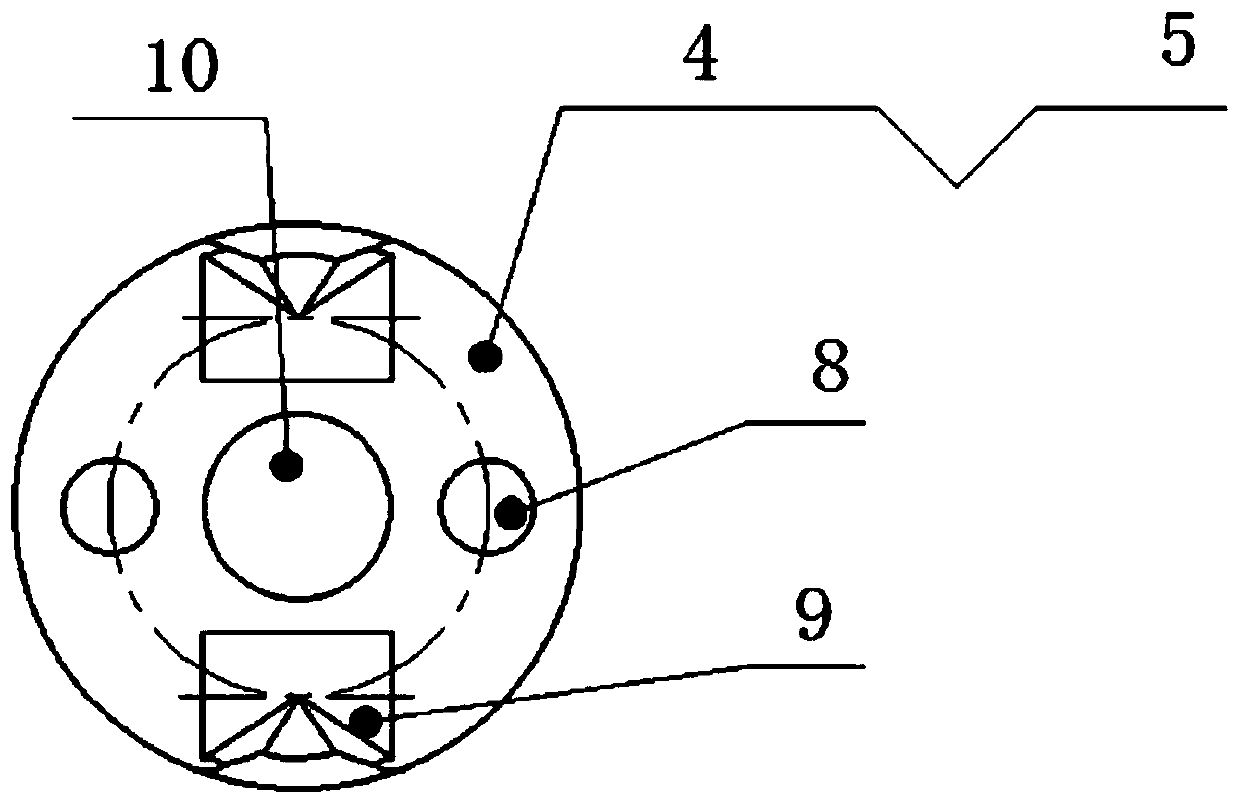

[0054] Such as image 3 As shown, the inner fixed washers 4, 5 include a centrally located shaft hole 10, two evenly distributed fixing holes 8, and two evenly distributed spring arm mounting grooves 9; the fixed holes 8 of the inner fixed washers 4, 5 The center of circle is on the intermediate circle between the inner and outer circles of the inner fixed washers 4 and 5; the spring arm mounting groove 9 of the inner fixed washers 4 and 5 includes a first end fixed pin 31 to cooperate with the cylindrical spring arm 3 The first fixed pin slot and the first fixed arm slot matched with the first straight arm 32 of the cylindrical spring arm 3, the connection between the first fixed pin slot and the first fixed arm slot adopts a circular arc transition , the ...

Embodiment 2

[0061] Such as Figure 10 to Figure 16 As shown, the leaf spring in this example includes three axially symmetrical cylindrical spring arms 30 with the same structure, outer fixing washers 10 , 20 and inner fixing washers 40 , 50 .

[0062] Such as Figure 12 As shown, the inner fixing washers 40, 50 include a shaft hole 100 at the center, three evenly distributed fixing holes 80, and three evenly distributed spring arm mounting grooves 90; the fixing holes 80 of the inner fixing washers 40, 50 The center of the circle is on the middle circle between the inner and outer circles of the inner fixed washers 40, 50; The first fixed pin slot and the first fixed arm slot matched with the first straight arm 302 of the cylindrical spring arm 30, the connection between the first fixed pin slot and the first fixed arm slot adopts a circular arc transition, the second A tail end of the fixed arm groove adopts a circular arc transition.

[0063] The inner fixing washers 40 and 50 of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com