Seal assembly used for hydraulic bushing and hydraulic bushing

A technology of sealing components and hydraulic bushings, applied in the directions of shafts and bearings, transportation and packaging, railway car body components, etc., can solve the problems of wheel and track wear, increase train operating costs, etc., and achieve the effect of increasing axial stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with accompanying drawing.

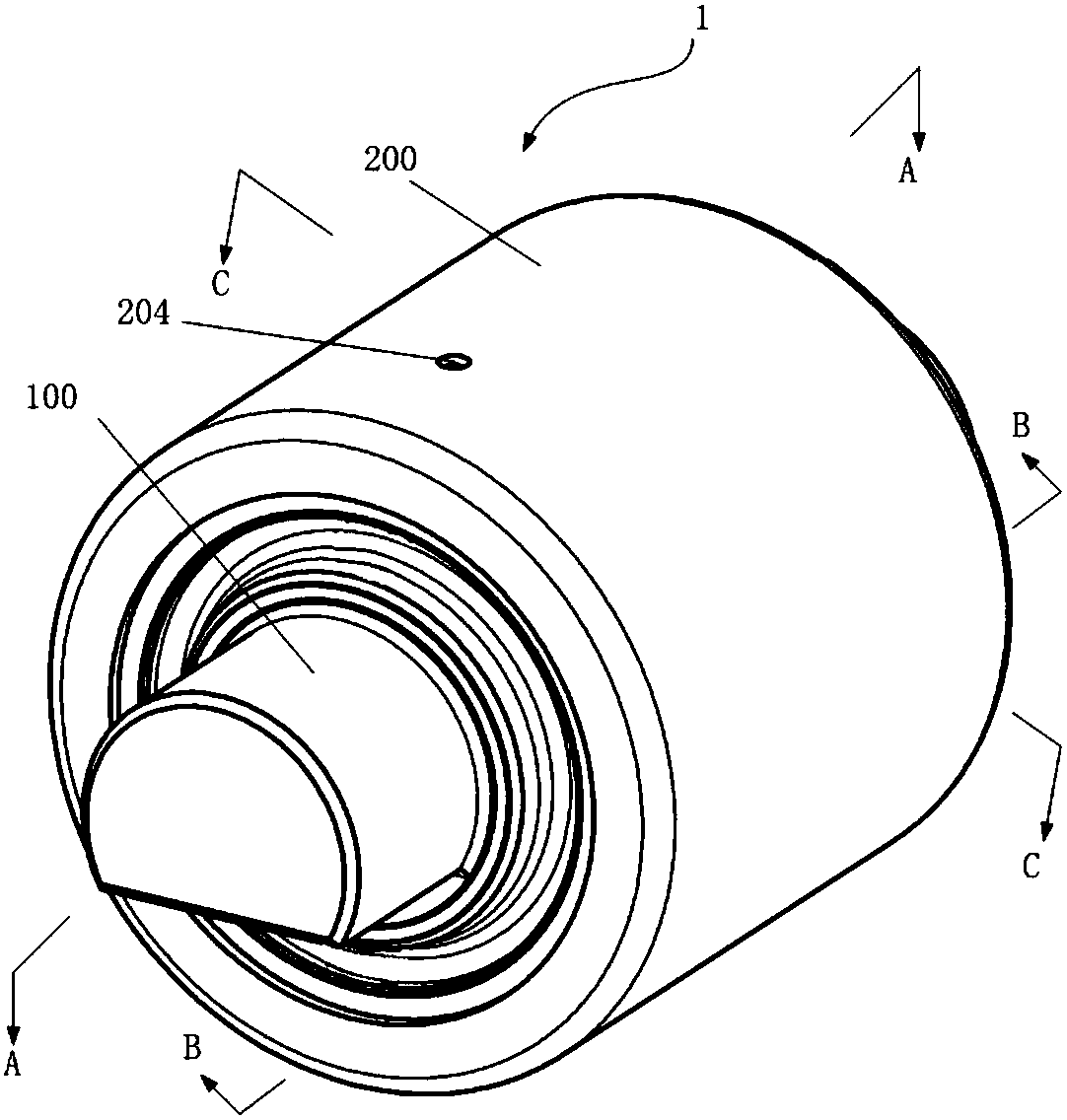

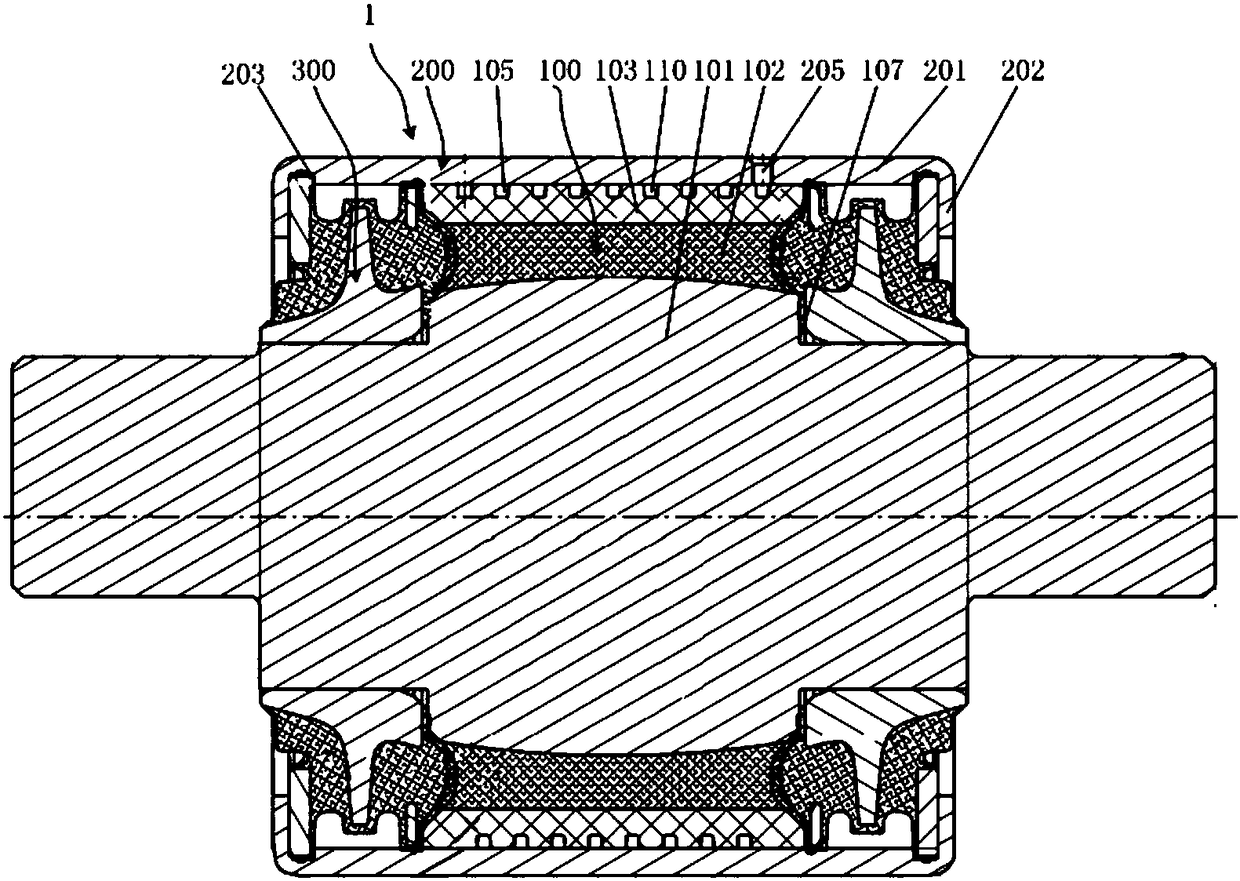

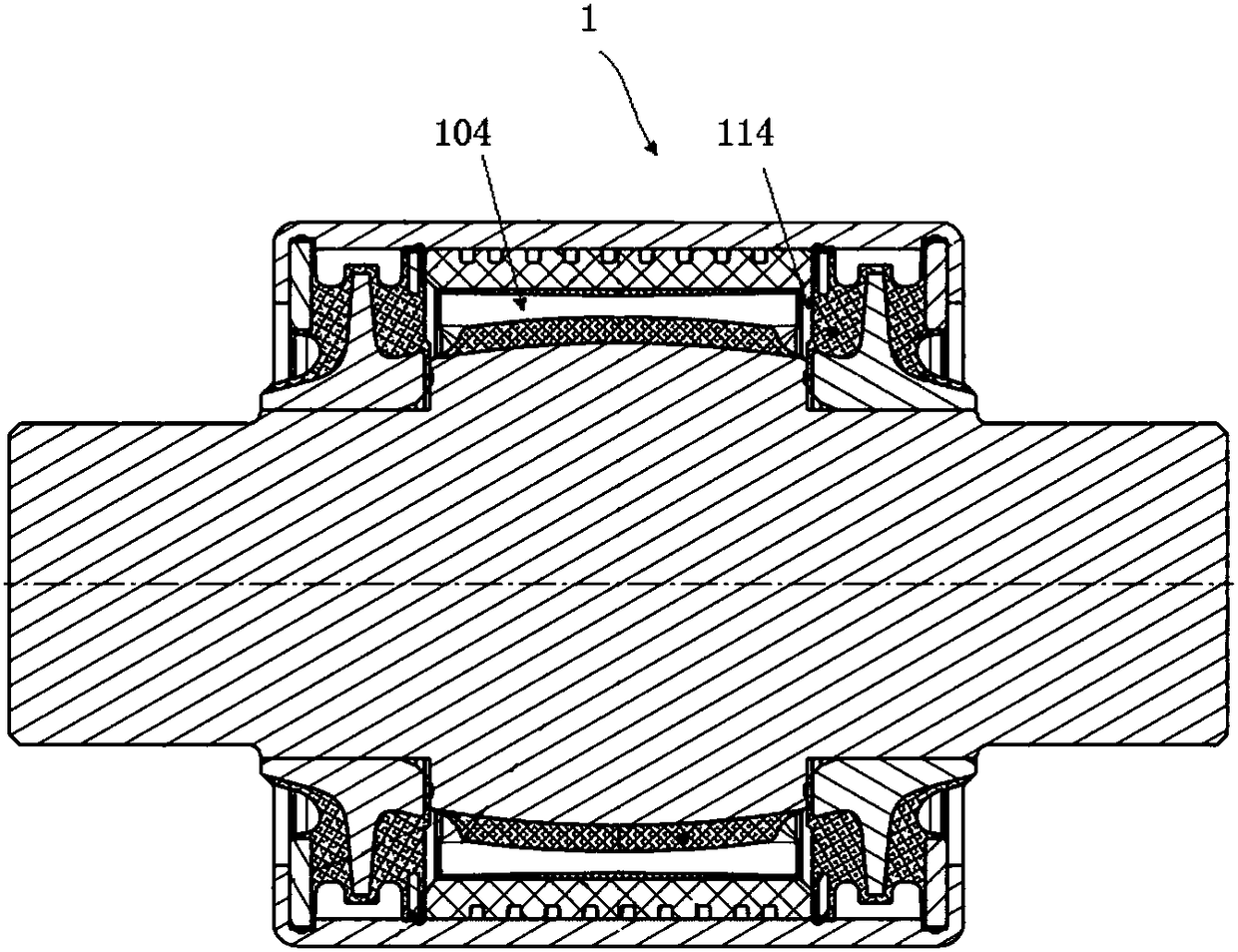

[0044] Such as figure 1 As shown, the hydraulic bushing 1 includes a main spring 100 and a cylindrical casing 200 . Such as figure 2 and 3 As shown, the main spring 100 has a mandrel 101 , a first rubber body 102 and a sleeve 103 . The first rubber body 102 is sheathed on the outer wall of the mandrel 101 . Two liquid chambers 104 are arranged on the first rubber body 102, and each liquid chamber 104 is a through hole penetrating along the axial direction of the first rubber body 102, and in the radial direction of the first rubber body 102, the two liquid chambers 104 Relative interval distribution. The sleeve 103 is sheathed on the outer wall of the first rubber body 102 . Meanwhile, a groove 110 is provided on the wall of the sleeve 103 . Wherein, the main spring 100 is disposed in the inner cavity of the casing 300 , so that the casing 300 and the sleeve 103 fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com