Floor brush and cleaning vacuum cleaner thereof

A rolling brush and scraper technology, applied in the direction of suction nozzles, etc., can solve problems such as low work efficiency, poor user experience, and inability to completely absorb sewage, and achieve the effect of thorough water absorption and high cleaning efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

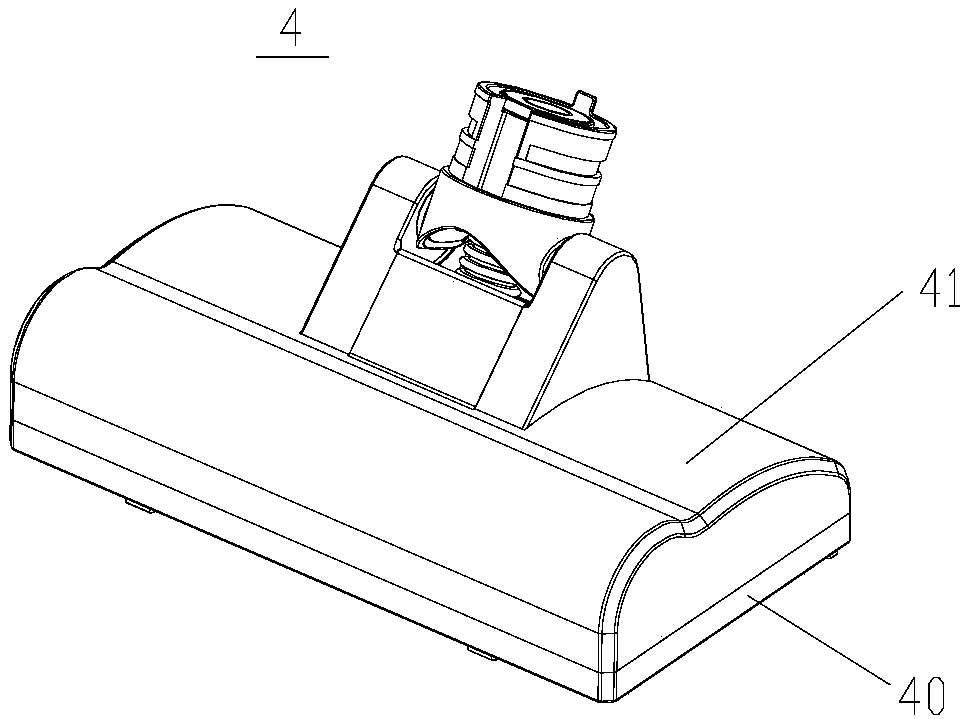

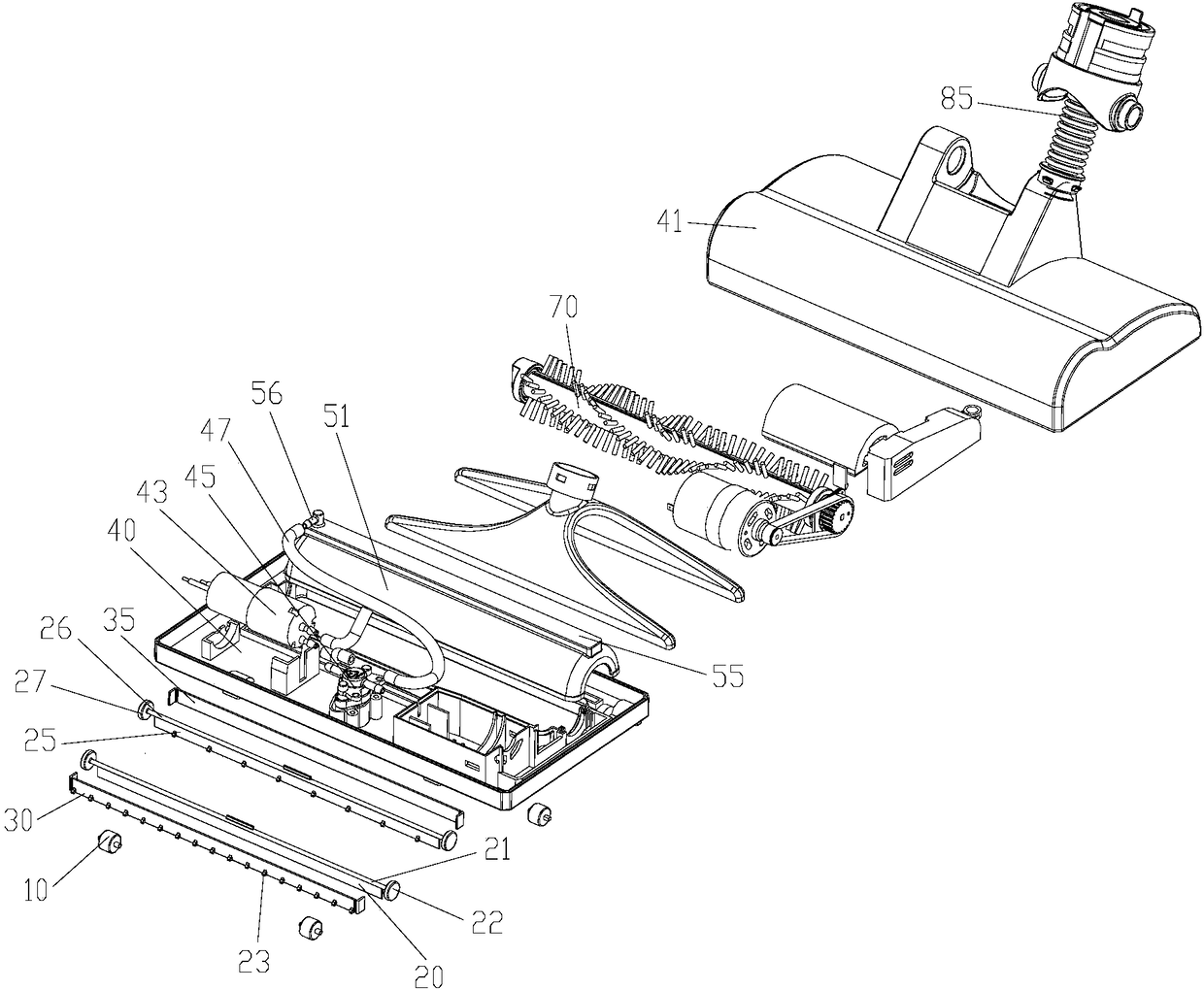

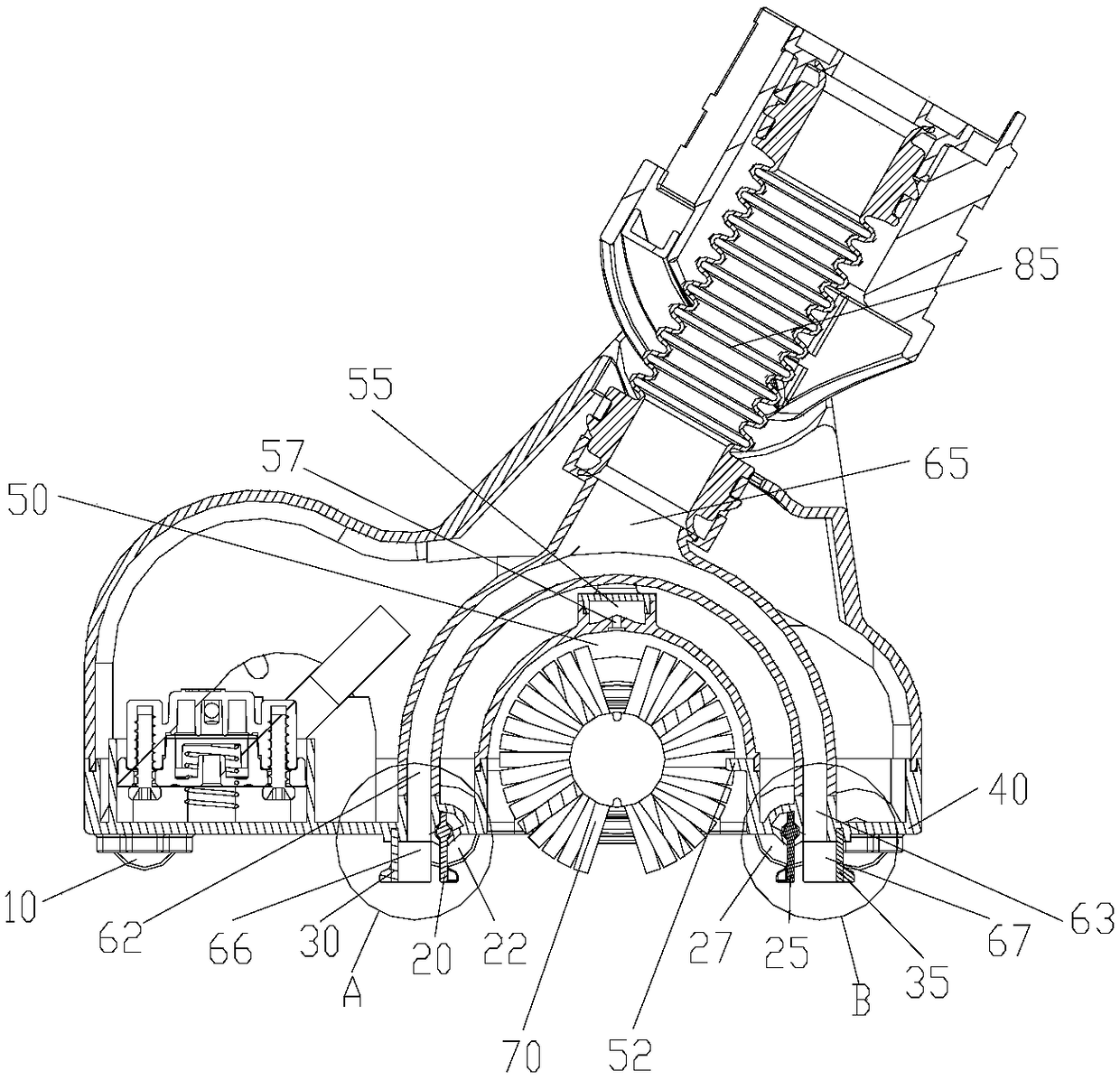

[0028] figure 1 It is a schematic diagram of the overall structure of the ground brush of the present invention; figure 2 Create an explosion map for the present invention; image 3 It is a sectional view of the ground brush of the present invention; Figure 4 for image 3 The enlarged view of the local structure of A; Figure 5 for image 3 The enlarged view of the local structure of B; Figure 6 It is a schematic diagram of the structure of the bottom surface of the brush of the present invention. combine Figure 1 to Figure 6 As shown, the present invention provides a floor brush, including a floor brush body 4 formed by fastening a floor brush base 40 and a cover 41, a rolling brush 70 is arranged in the floor brush body, and an air inlet is provided on the floor brush base. The rolling brush 70 is arranged in the rolling brush cavity 50, and the rolling brush cavity 50 is formed by buckling the rolling brush cover plate 51 and the ground brush base 40; the bottom ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap