Facility and method for treating edible mushroom culture materials

A culture material and edible fungus technology, which is applied in the application, fertilization device, fertilizer mixture and other directions, can solve the problems of difficulty in grasping the appropriate water content of the culture material, excessively high water content of the culture material, and long stacking time of the culture material, and achieves a high level of improvement. The effect of water absorption, improving treatment quality and inhibiting reproduction and growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

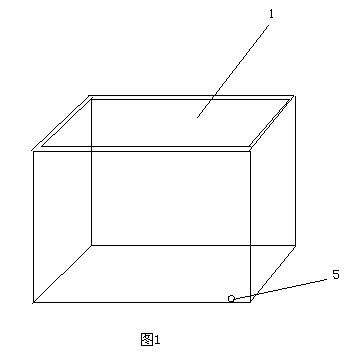

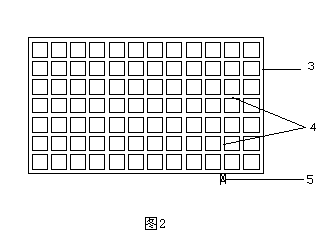

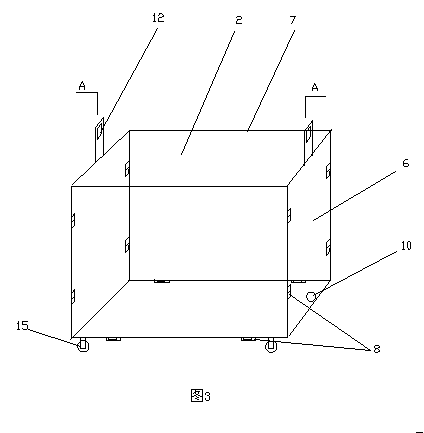

[0022] For implementing the present invention, as figure 1 , figure 2 As shown, at first a masonry-concrete structure with a length of 300cm, a width of 200cm, and a leaching pool 1 of 100cm is built, and at the bottom of the leaching pool 3, a drain tank 4 with a depth of 3 cm and a width of 3 cm is arranged vertically and horizontally every 10 cm. communicated and communicated with the outside world through the drain valve 5. Such as image 3 , Figure 4 As shown, build the pressure pool 2 with the long 100cm, wide 80cm, and high 80cm of the inner diameter of the pool with the brick-concrete structure, the bottom of the pressure pool is fixedly connected with the symmetrical two short side pool walls to form two fixed pool walls 6, and then make the long 99cm, There are two movable wall panels 7 with a height of 79.5cm. The movable wall panels 7 are movably connected with the bottom of the press pool and the fixed pool wall 6 with bayonet pins 8. The bottom of the press ...

Embodiment 2

[0028] For implementing the present invention, as figure 1 , figure 2 As shown, at first a masonry-concrete structure is used to build a leaching pool 1 with a length of 250 cm, a width of 160 cm, and a height of 120 cm. At the bottom of the leaching pool 3, a drain tank 4 with a depth of 3 cm and a width of 3 cm is arranged vertically and horizontally every 15 cm. communicated and communicated with the outside world through the drain valve 5. Such as image 3 , Figure 4 As shown, the press pool 2 is constructed by welding with iron plates. The inner diameter of the pool is 80 cm long, 80 cm wide, and 100 cm high. Any two symmetrical sides of the press pool are set as fixed pool walls 6. Two movable wall panels 7 with a height of 79.5 cm are movably connected with the bottom of the press pool and the fixed pool wall 6 with bayonet pins 8, and the bottom of the press pool and the inner sides of the two fixed pool walls 6 are provided with drainage holes 9. The drainage ho...

Embodiment 3

[0034] For implementing the present invention, as figure 1 , figure 2 As shown, at first build the soaking tank 1 identical with embodiment 2 with brick-concrete structure. Such as Figure 5 As shown, a brick-concrete structure is used to build a press tank 2 with a length of 160 cm, a width of 120 cm, and a height of 120 cm on the extension line of the dipping tank 1. A short wall and a long wall of the press pool 2 are a shared fixed pool wall, and then a movable wall plate 7 and a press pool cover 11 on the outside are made, and the movable wall plate 7 is connected with the bottom of the press pool and the fixed pool. The walls 6 are movably connected with bayonet pins 8, and the bottom of the press pool and the inner side of the fixed pool wall 6 are provided with a drainage hole 9, which communicates with the bottom of the press pool and the fixed pool wall 6, and communicates with the outside world through the drain port 10. Connected, the top of the fixed pool wall...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap