Rope winder

A winding machine and rope technology, applied in the direction of conveying filamentous materials, thin material processing, transportation and packaging, etc., can solve the problems of concentrated winding of ropes in one place, lack of dust removal mechanism in winders, etc. Good roll quality, high winding automation coefficient, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

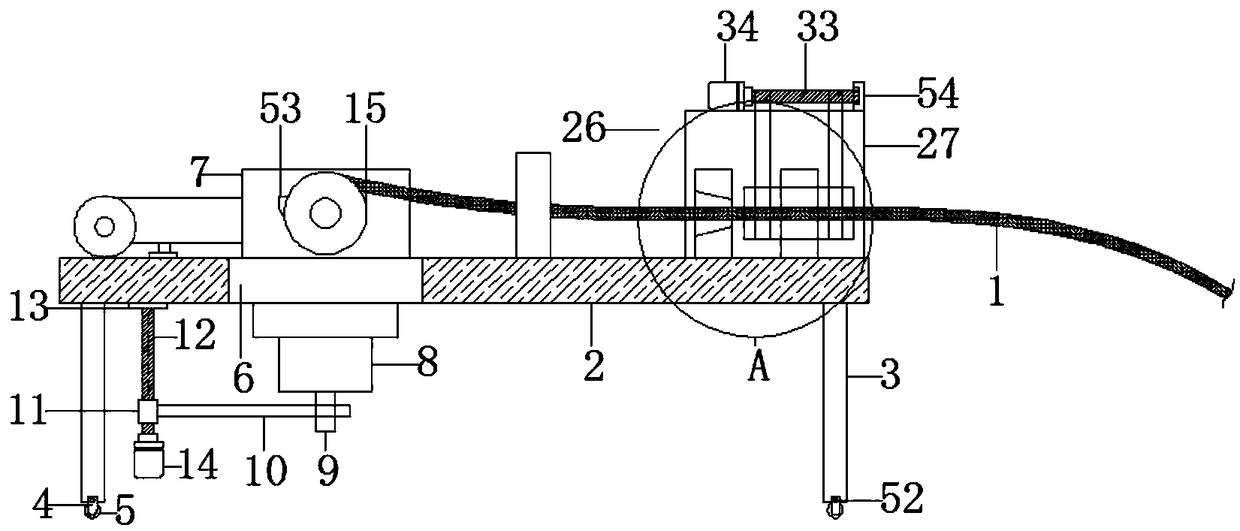

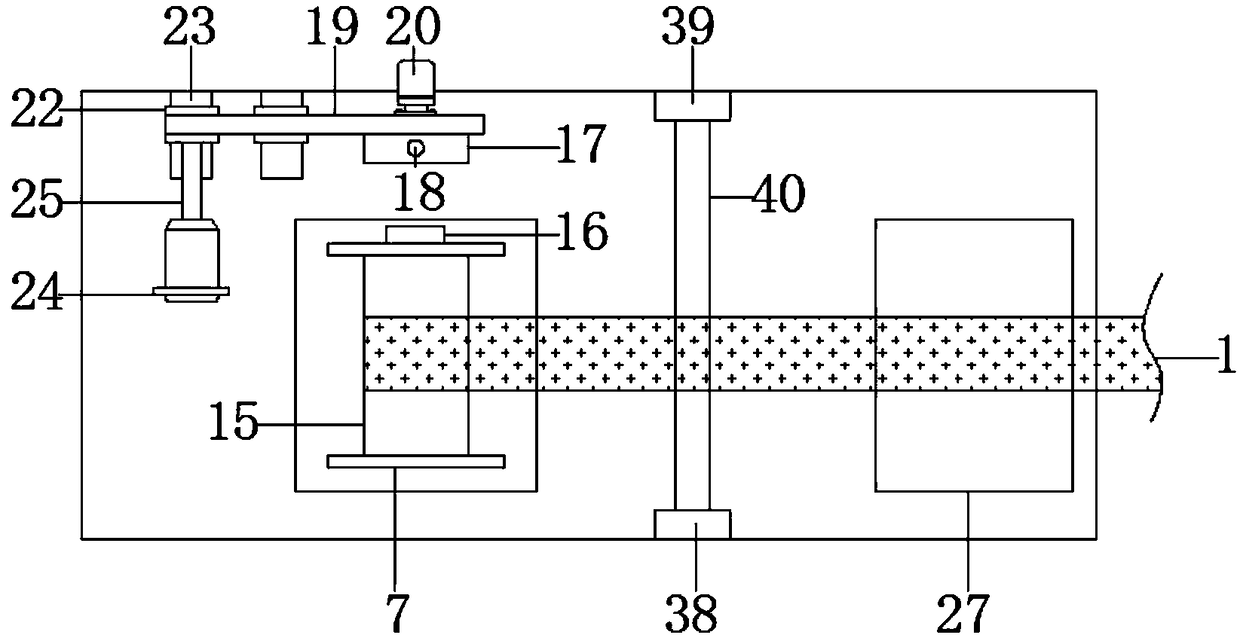

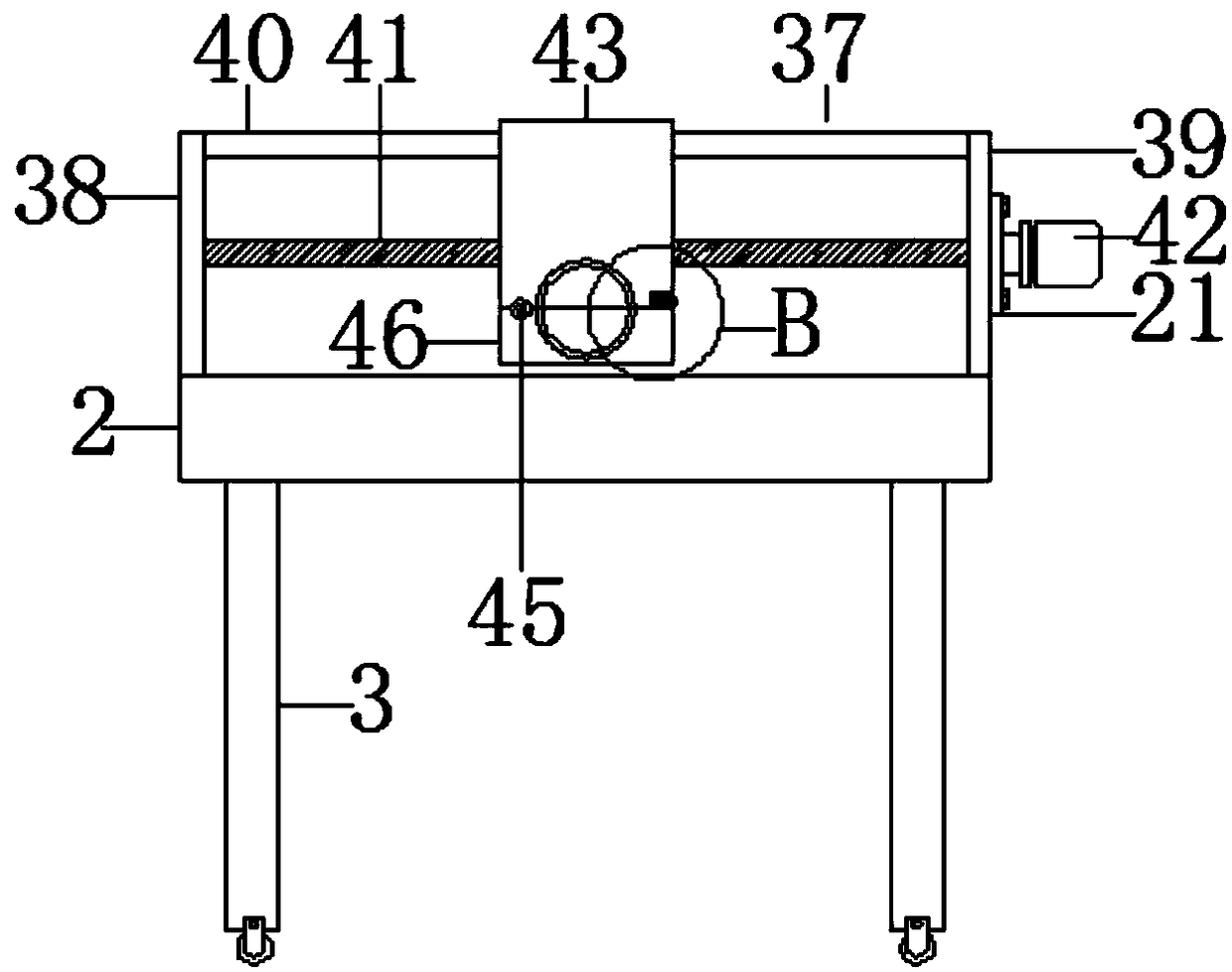

[0022] Such as Figure 1-6 As shown, this specific embodiment adopts the following technical solutions: a rope winding machine, comprising a rope 1 and a winding platform 2, characterized in that four support columns 3 are arranged below the winding platform 2, and the bottom ends of the support columns 3 are The moving wheel 5 is connected with the connecting frame 4, and the winding platform 2 is provided with a winding platform gap 6, and the winding platform gap 6 is provided with a winding frame 7, and the winding frame 7 is made as a U-shaped structure, and the winding frame 7 The lower end is fixedly connected with the transmission frame 8, the bottom end of the transmission frame 8 is connected with the transmission rod 10 through the transmission shaft 9, the other end of the transmission rod 10 is connected with the moving block 11, the moving block 11 is sleeved on the threaded rod 12, and the upper end of the threaded rod 12 is connected In the bearing seat 13 on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com