A combustion-to-detonation wave velocity measurement device

A combustion-to-detonation and measuring device technology, which is applied in the direction of offensive equipment, ammunition testing, ammunition, etc., can solve problems such as reflection inhomogeneity, and achieve the effects of reduced strength influence, good safety performance, and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further explained by specific examples below.

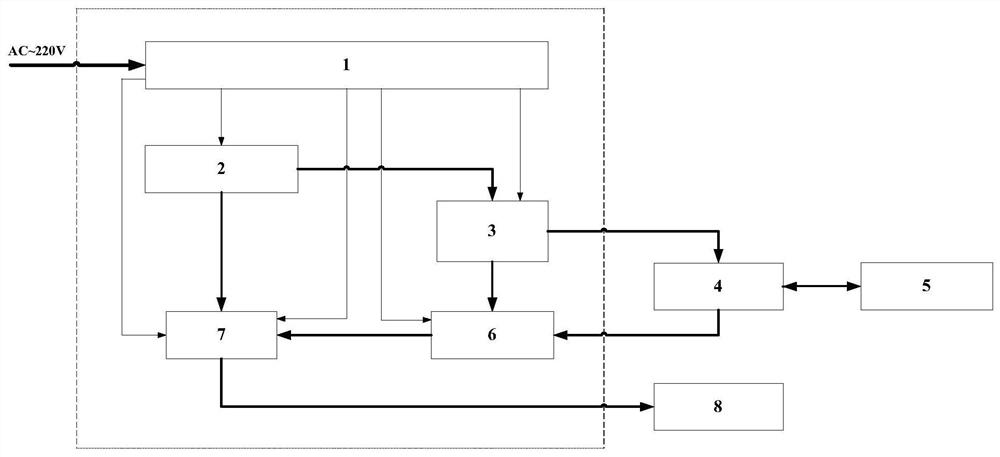

[0035] The measurement device is designed according to the characteristics of combustion-to-detonation wave velocity measurement, such as figure 1 , including a microwave sensor probe 5, a signal generation module 2, a cancellation module 3, a transceiver front-end module 4, a down-conversion module 6, a signal processing module 7, a data processing module, a display terminal 8 and an AC-DC power supply module 1.

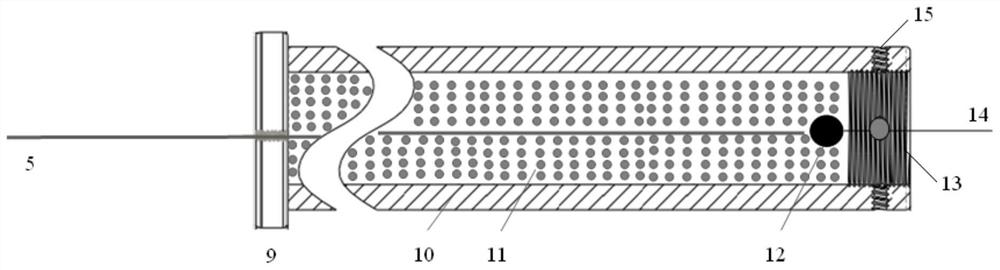

[0036] The microwave sensor probe 5 is a single armored miniature cable, φ1mm×500mm, 1m long, and its layout in the sample tube is as follows: figure 2. Arranged inside the explosive charge 11 along the axial direction, against the ignition device 12, the head is located at the ignition end, and the tail passes through the microhole in the center of the plug 9 at the bottom of the sample tube, and is pluggable with a 15m long radio frequency cable. Then, the radio frequency cable...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com