Wave velocity microwave phase shift measurement method in combustion-to-detonation process

A combustion-to-detonation and phase-shift measurement technology, which is applied to devices using electrical/magnetic methods, etc., can solve problems such as weakening the confinement strength of the sample tube, deviation of measurement results, and influence on judgment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

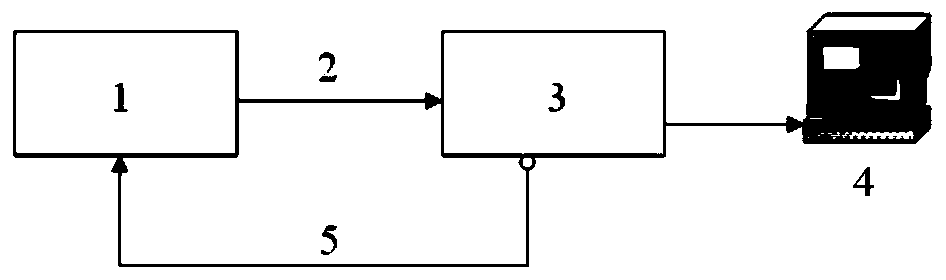

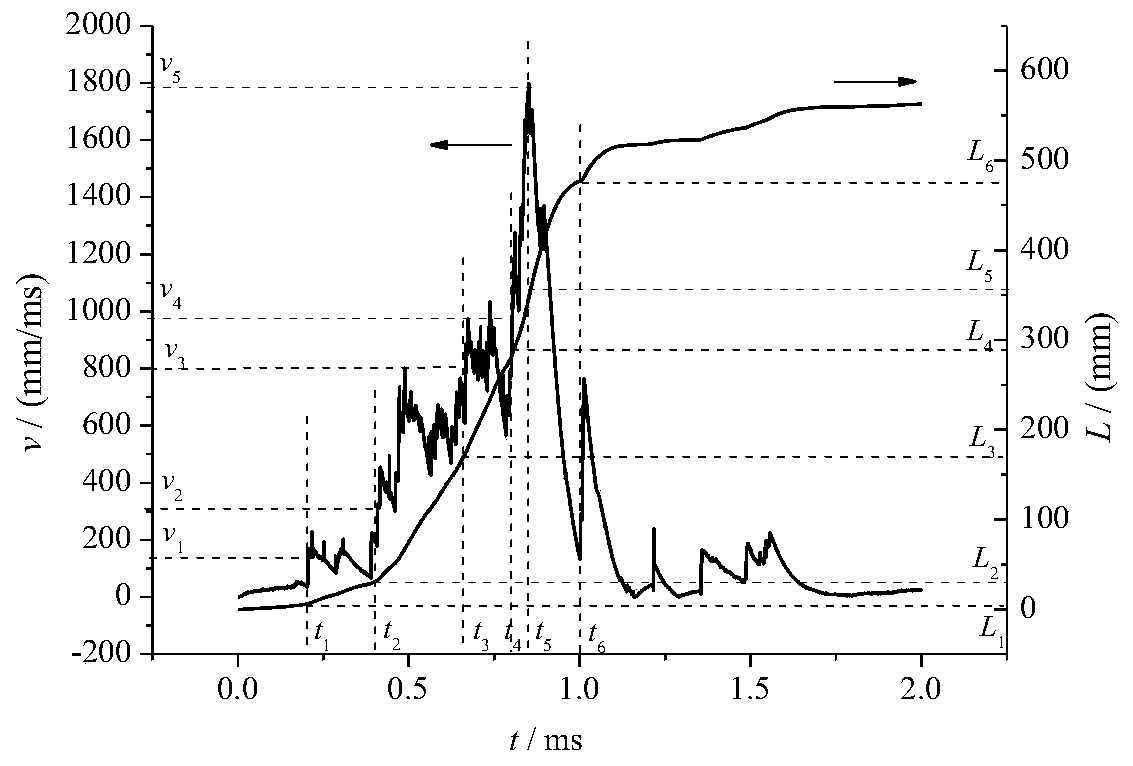

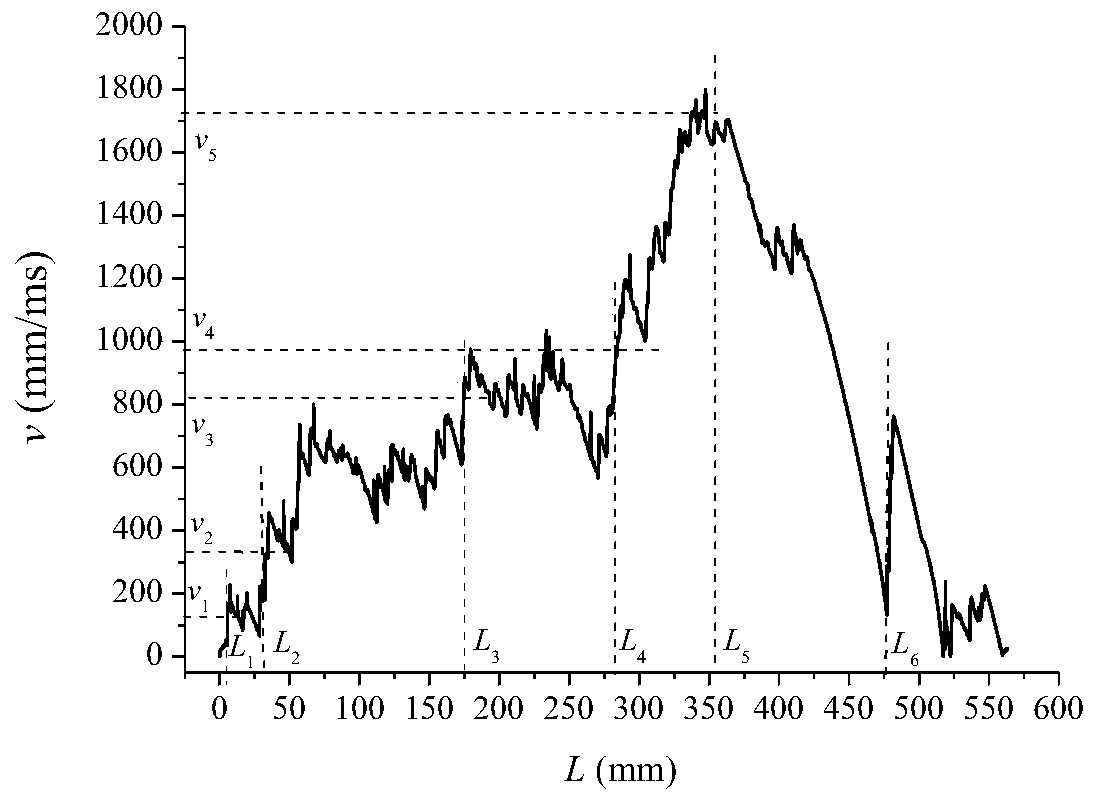

[0067] A method for measuring wave velocity and microwave phase shift in combustion-to-detonation process. The test method includes test preparation, test steps, data processing and result expression.

[0068] 1. Test preparation, including:

[0069] 1.1 Calibration of microwave phase shift test device

[0070] Turn on the system power of the microwave phase-shift testing device, and after preheating, the microwave phase-shift testing device performs normalization processing on the collected echoes. Use a special tool to cut off the known length of the microwave sensor probe to avoid phase ambiguity. The length cut each time should be smaller than the guided wavelength in the probe. Use a measuring tool with an accuracy better than 0.5mm to measure the length of the cut probe. Compare the test distance given by the phase shift test device to obtain the distance measurement accuracy; control the phase of the beacon output signal to obtain the phase change rate corresponding to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com