Welded high-strength wheel

A high-strength, welded technology, applied in the manufacture of web-plate wheels, wheels, wheels, etc., can solve the problems of poor fatigue durability test results, loose fit of spokes and rims, etc., and achieve light weight, enhanced strength, and low emissions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

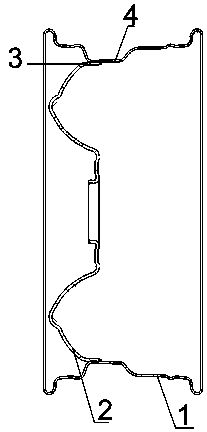

[0009] exist figure 1 Among them, a high-strength wheel, consisting of a rim 1 and a spoke 2, is characterized in that: the groove bottom 4 of the rim 1 forms an angle of 1° with the horizontal line, and the skirt 3 of the spoke 2 forms an angle of 1° with the horizontal line Angle, the groove bottom 4 of the rim 1 and the skirt 3 of the spoke 2 are welded together.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com