Bench-work pin puller

A technology of pin puller and fitter, which is applied in the manufacture of tools and hand-held tools, etc. It can solve the problems of poor cushioning capacity of the convex handle, hand vibration, and inconvenient use, and achieves the effects of high safety, reduced use cost, and comfortable use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

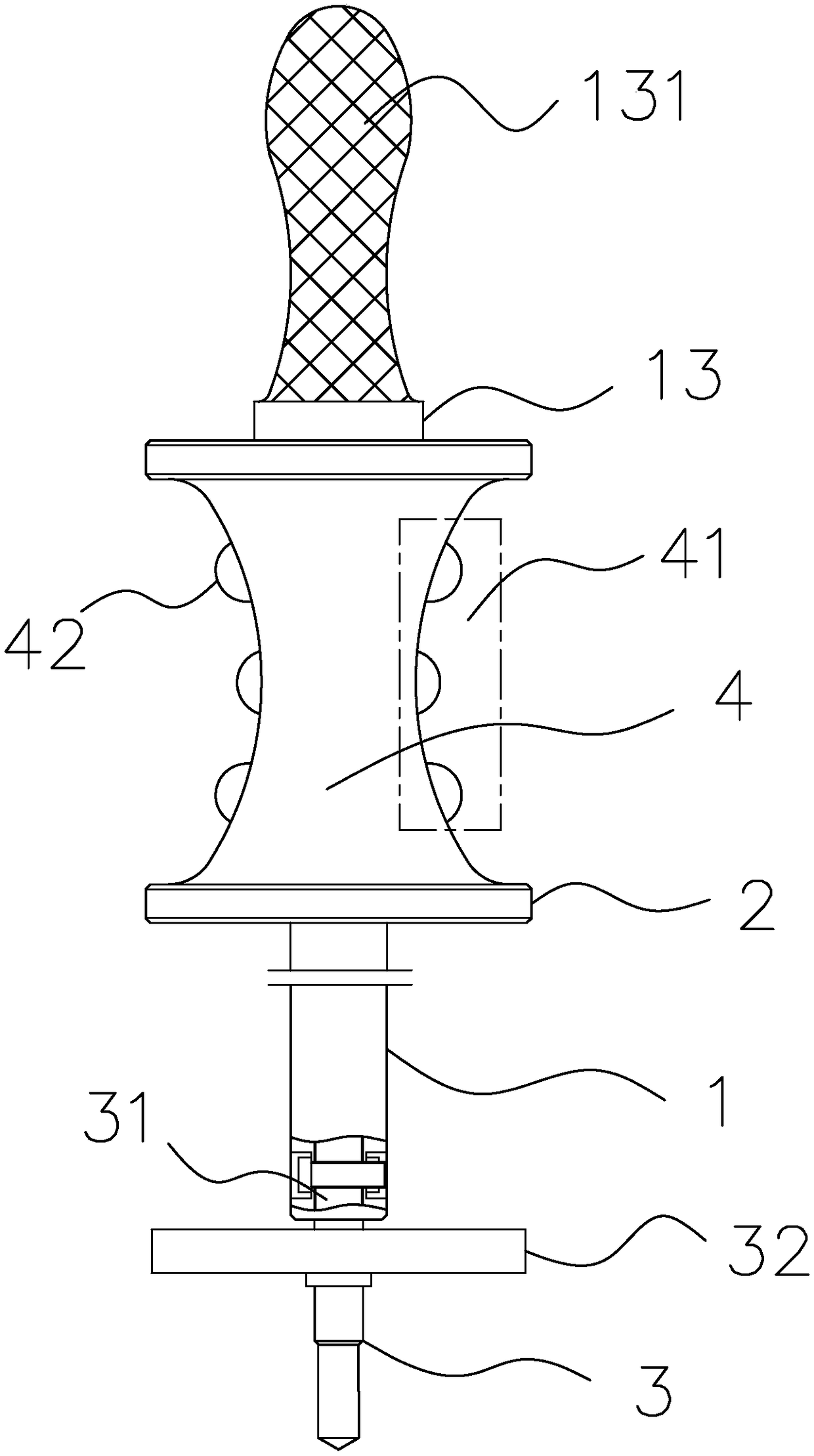

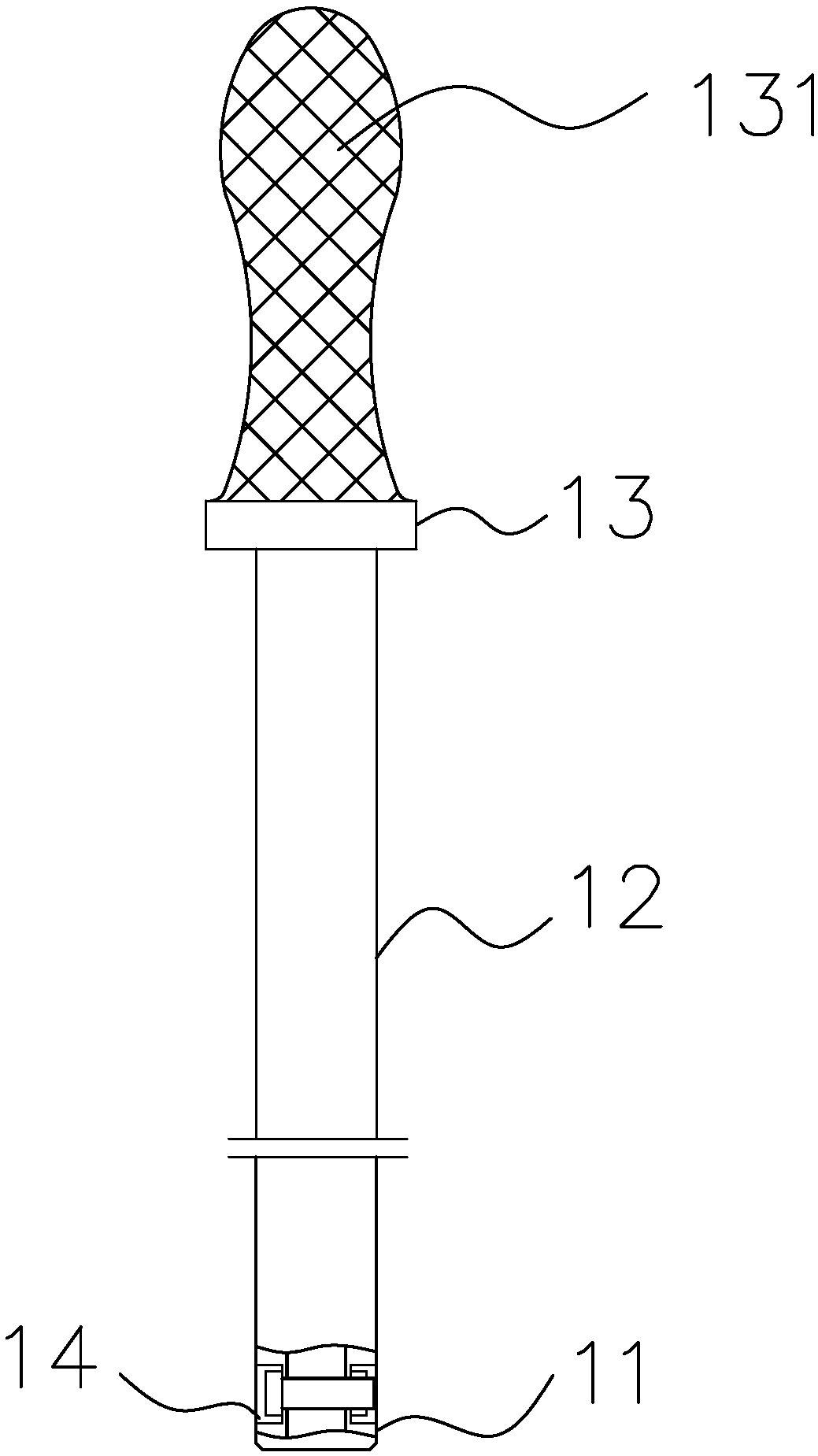

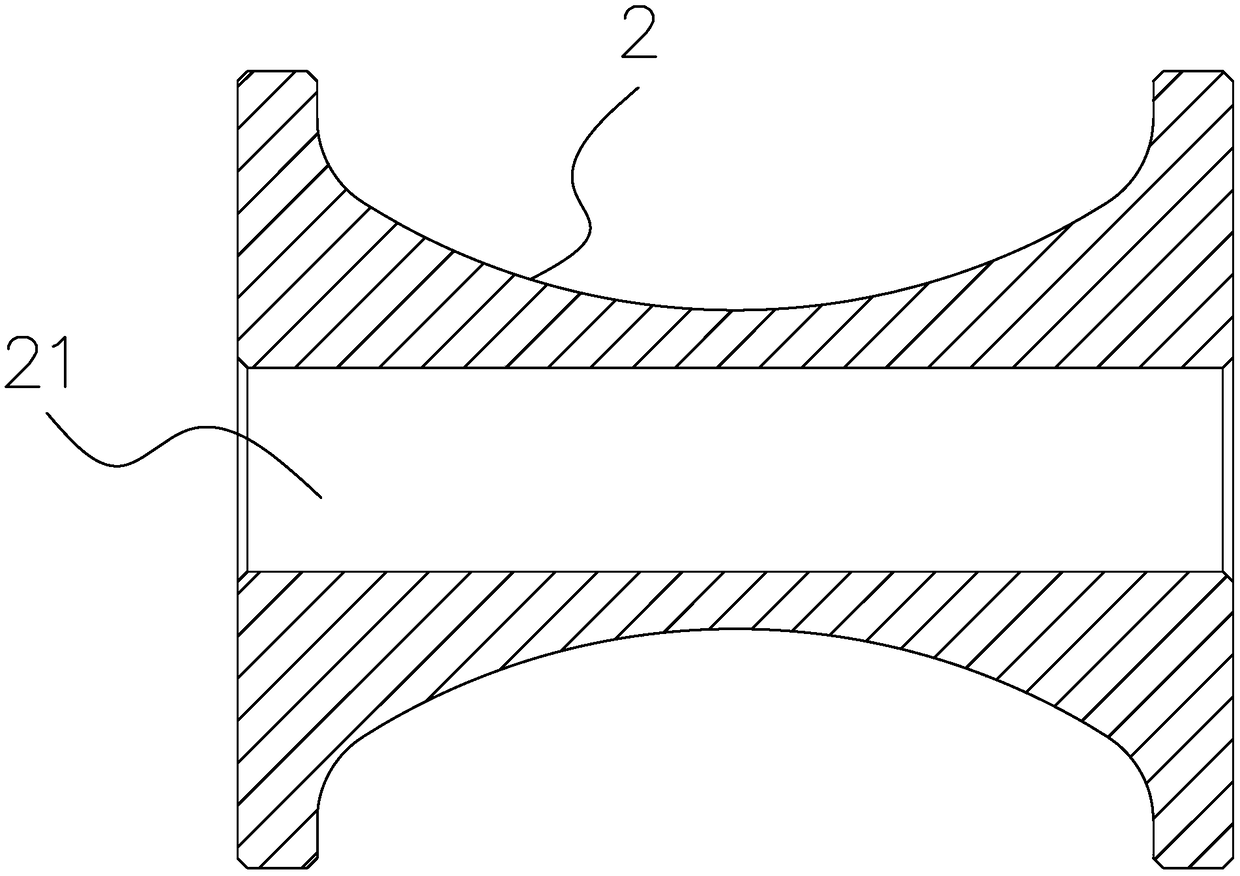

[0024] This embodiment discloses a fitter's pin puller, which includes a pull rod 1, a sleeve rod 2, and a pulling head 3. The sleeve rod 2 is sleeved on the pull rod 1, and the pull head 3 is installed at the end of the pull rod 1. The pull rod 1 includes, from bottom to top, a connecting end 11 for connecting with the pulling head 3, a straight rod 12 for socketing the sleeve rod 2, and a lug 13 for impacting and pulling the pin with the sleeve rod 2. The lug The diameter of 13 is greater than the diameter of the straight rod 12. The sleeve rod 2 is a single-leaf hyperboloid structure. The central axis of the sleeve rod 2 is provided with a through hole 21 for being sleeved on the pull rod 1. The diameter is larger than the diameter of the straight rod 12. One end of the pulling head 3 is provided with a connection position 31 connected to the connecting end 11, and the other end of the pulling head 3 is provided with a thread for connecting with a pin. The pulling head 3 an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com