36-inch single-barrel double-wellhead oil extraction device

An oil production device and single-tube technology, which is applied in earthwork drilling, wellbore/well components, sealing/isolation, etc., can solve problems such as poor sealing performance, and achieve the effect of improving sealing performance and strengthening sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

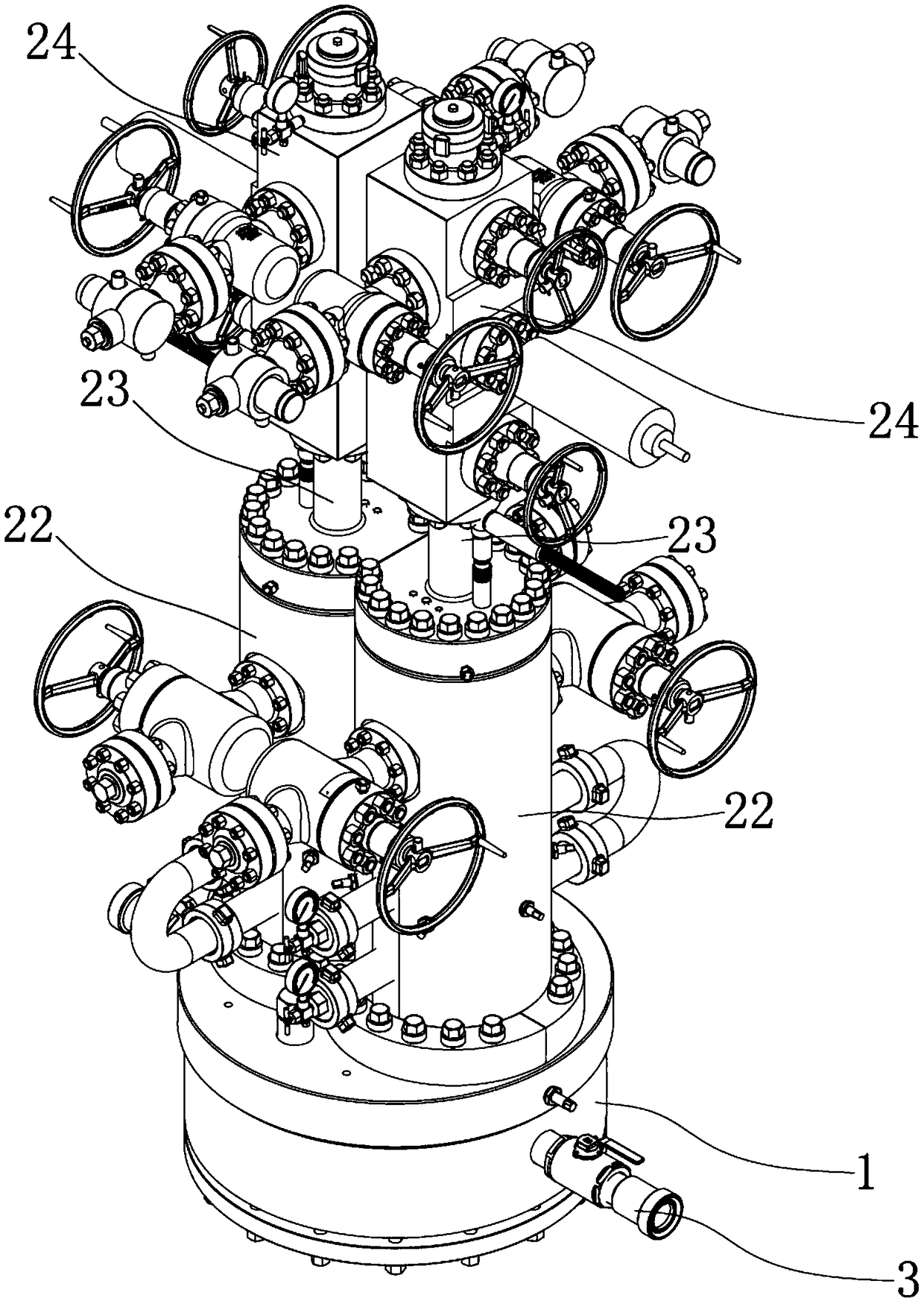

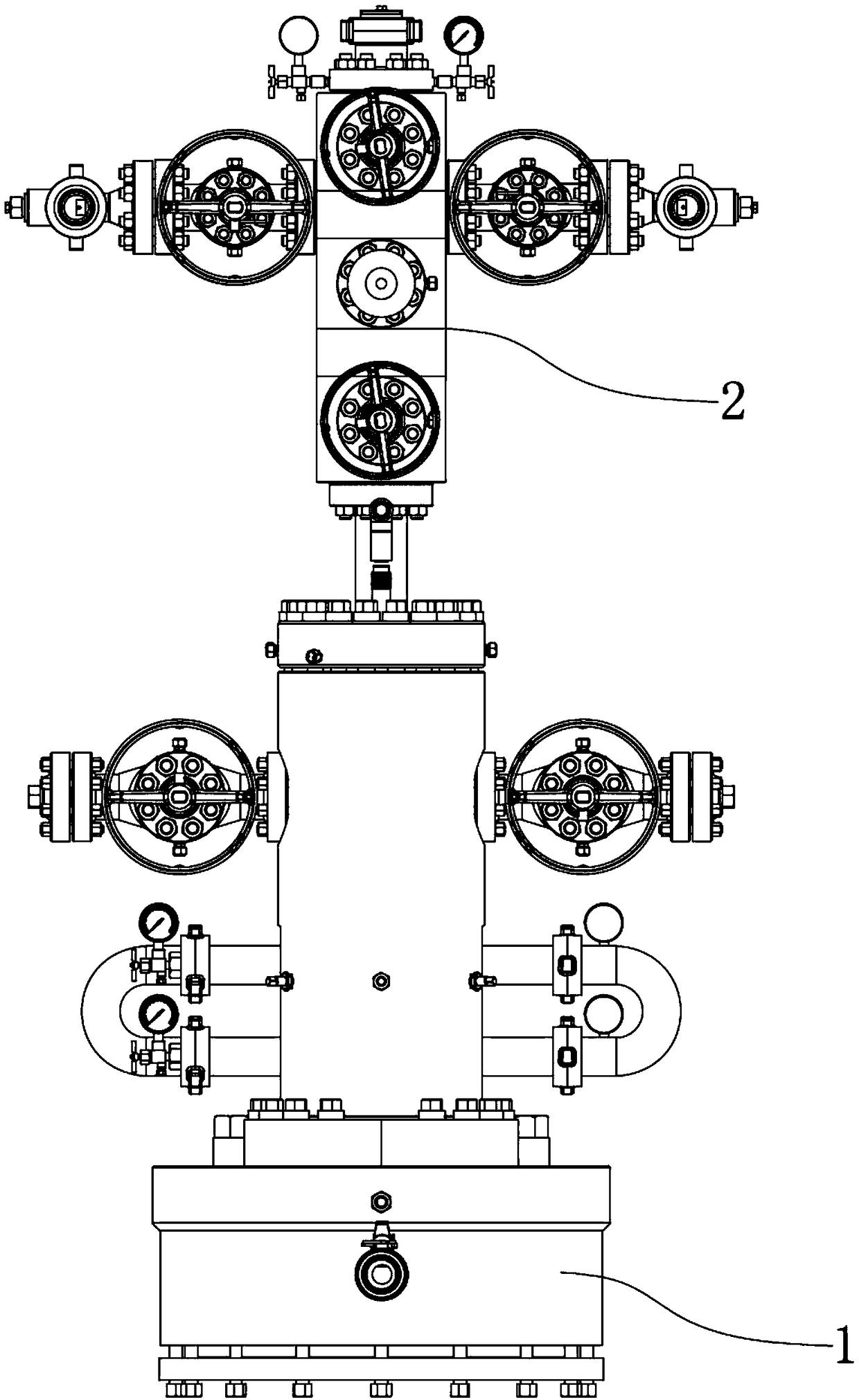

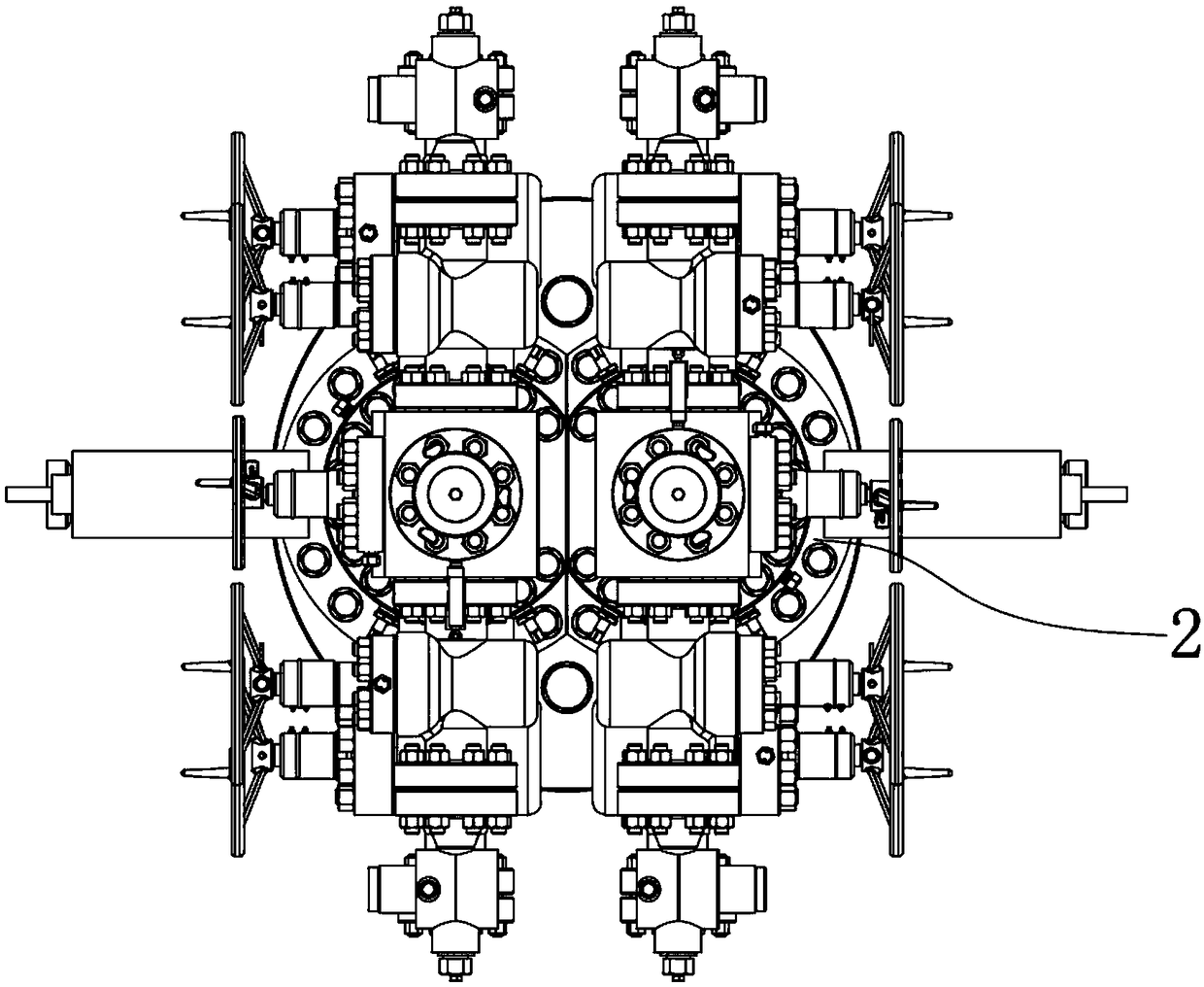

[0027] see Figure 1 to Figure 6 , the figure shows a 36-inch single cylinder double wellhead oil production device provided by Embodiment 1 of the present invention, which includes a base 1 and two oil production mechanisms 2, the base 1 has a bottom plate 11, and an installation sleeve 12 is fixedly installed on the bottom plate 11. The installation sleeve 12 has two installation positions 121 corresponding to the two oil production mechanisms 2. A 36-inch inverted slip 13 is installed in the installation sleeve 12, and a first casing 14 is fixedly installed on the 36-inch inverted slip 13. A plurality of 36-inch O-rings 15 are arranged between the outer wall and the inner wall of the installation sleeve 12, and the plurality of 36-inch O-rings 15 are arranged equidistantly along the axial direction of the first casing 14, and the two oil production mechanisms arranged symmetrically 2. Fixedly installed on the base 1, the oil production mechanism 2 has a second casing 21, th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap