Chain sleeve capable of achieving automatic lubricating adjustment through centrifugal force

An automatic lubrication and centrifugal force technology, applied in the chain field, can solve problems such as sleeve and roller wear, poor lubrication conditions, etc., and achieve the effect of saving lubricating oil and automatically adjusting the amount of lubricating oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

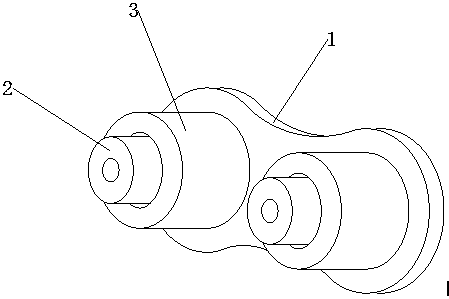

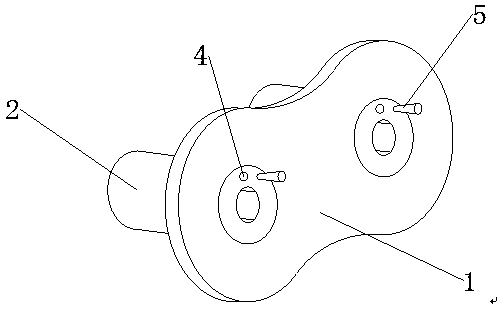

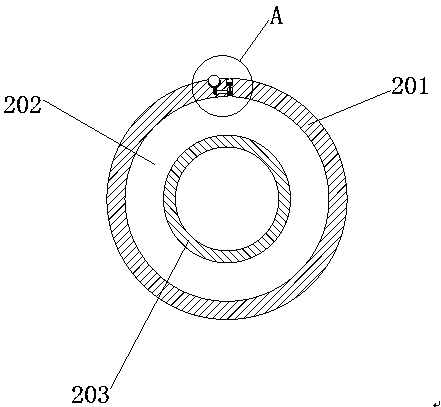

[0028] as attached figure 1 to attach Figure 5 Shown:

[0029] The present invention provides a chain bushing that utilizes centrifugal force to realize automatic lubrication adjustment, including an inner chain plate 1, a bushing 2, a bushing outer wall 201, an oil storage chamber 202, a bushing inner wall 203, a roller 3, a rolling groove 301, a lubricating Groove 302, filling port 4, sealing pin 5, ball 6, rolling chamber 7, oil-absorbing cotton 8, oil guide hole 9, spring 10, cavity 11, expansion block 12, connecting rod 13, oil guide port 14, sealing plug 15 , the inside of the inner chain plate 1 is plugged with a sleeve 2, and the outer circumference of the sleeve 2 is rollingly connected with a roller 3, and one end surface of the sleeve 2 is provided with an oil filling port 4, and the oil filling port 4 is inserted with a sealing pin 5, and the sleeve 2 includes sleeve outer wall 201, oil storage chamber 202, sleeve inner wall 203, oil storage chamber 202 is locat...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap