An intelligent safety management and control system for substation maintenance operations

A technology of safety control and substation, applied in the direction of electric transmission signal system, electrical components, supervision desk/panel, etc., can solve the problems of human visual dead angle, human monitoring fatigue cycle, visual dead angle, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

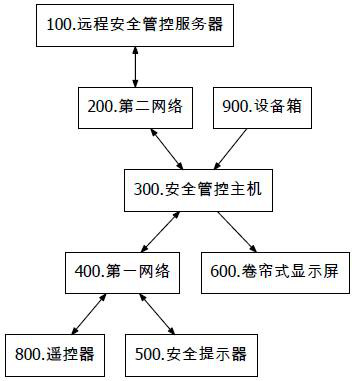

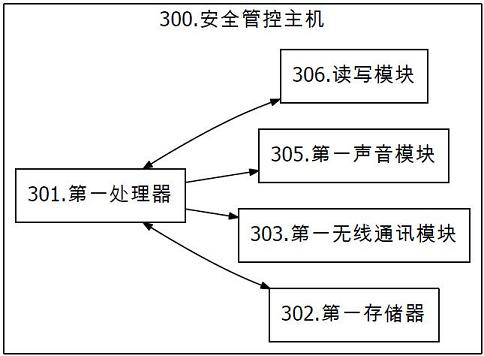

[0036] Such as figure 1As shown, this embodiment is an intelligent safety management and control system for substation maintenance operations, which is used for safety management and control of the maintenance work site, and can send data back to the remote safety management and control server 100 for recording safety management and control data and updating safety management and control measures. Hereinafter referred to as the system, it includes: a security control host 300 communicating with the remote security control server 100 through the second network 200, a rolling screen display 600 serving as a visual presentation device for the output content of the security control host 300, and multiple security control hosts. 300 through the first network 400 data communication safety reminder 500 and the remote controller 800 connected to the first network 400 and used to remotely control the security management host 300 and the safety reminder 500, and also includes a device th...

Embodiment 2

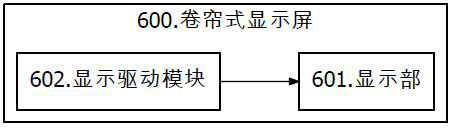

[0050] The difference between this embodiment and the first embodiment is that a different solution is used for the display mode of the rolling screen in the first embodiment. In this embodiment, the display portion 601 of the roll-up display screen 600 is a projection screen, and does not include a display driver module 602; Figure 10 As shown, the security management host also includes a first projection module that outputs images to the projection screen.

Embodiment 3

[0052] The difference between this embodiment and Embodiment 1 and Embodiment 2 is that this embodiment is a low-cost on-site safety management and control system. Specifically, the security management and control host in this embodiment is not connected to the remote security management and control server, and the second projection module of the security reminder is composed of a static cover plate carrying warning text, a high-brightness red LED, an electric focusing lens group, and is used for a remote control. It is used to switch the safety reminder and adjust the focal length of the electric focusing lens group.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com