Device used for grinding plants

A plant and grinding technology, which is applied in the field of plant grinding devices, can solve problems such as abnormality of the equipment, certain requirements for the height of the discharge port, and inconvenient removal of the materials entering the feed port, etc., so as to increase the life of the equipment and maintain Equipment cleanliness, easy to clean effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

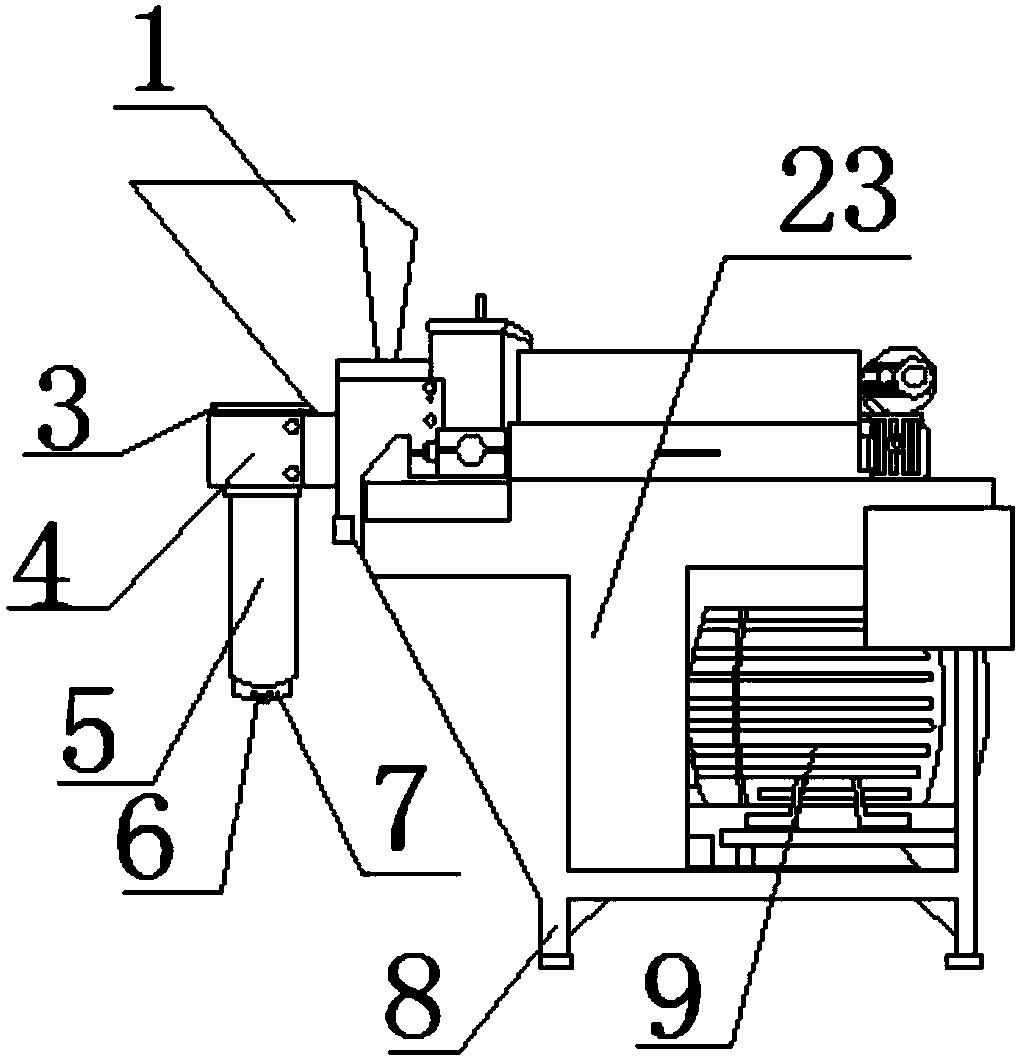

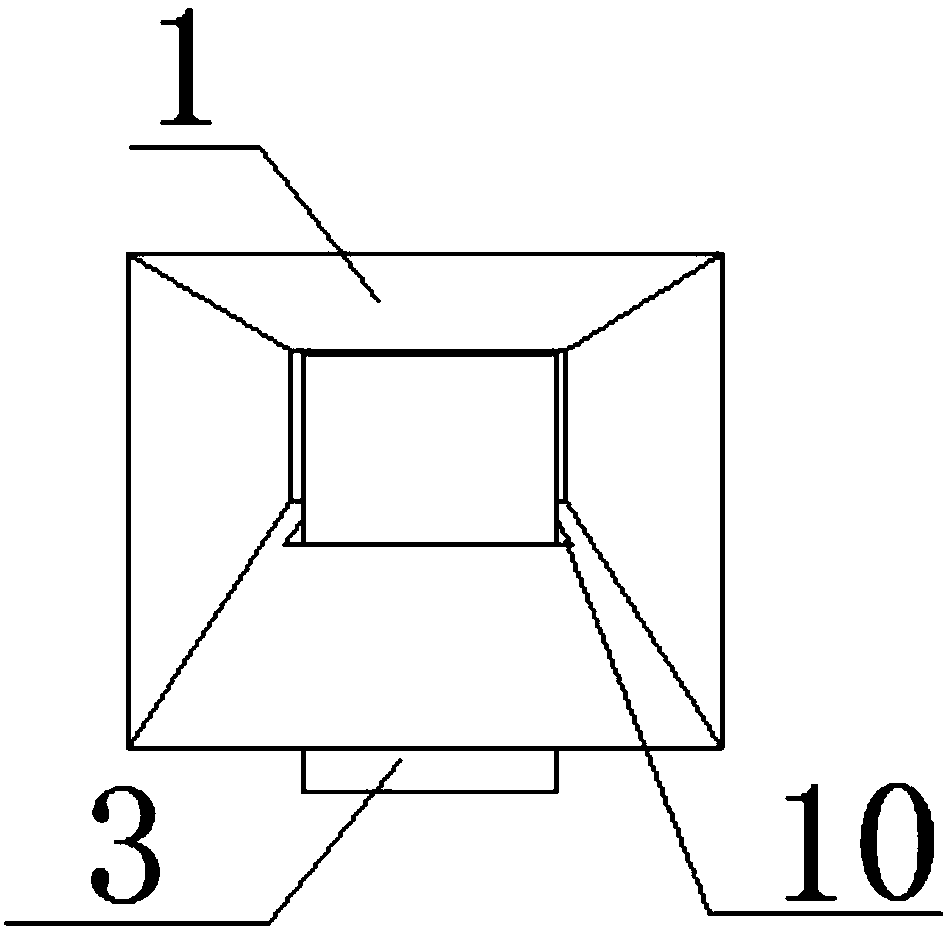

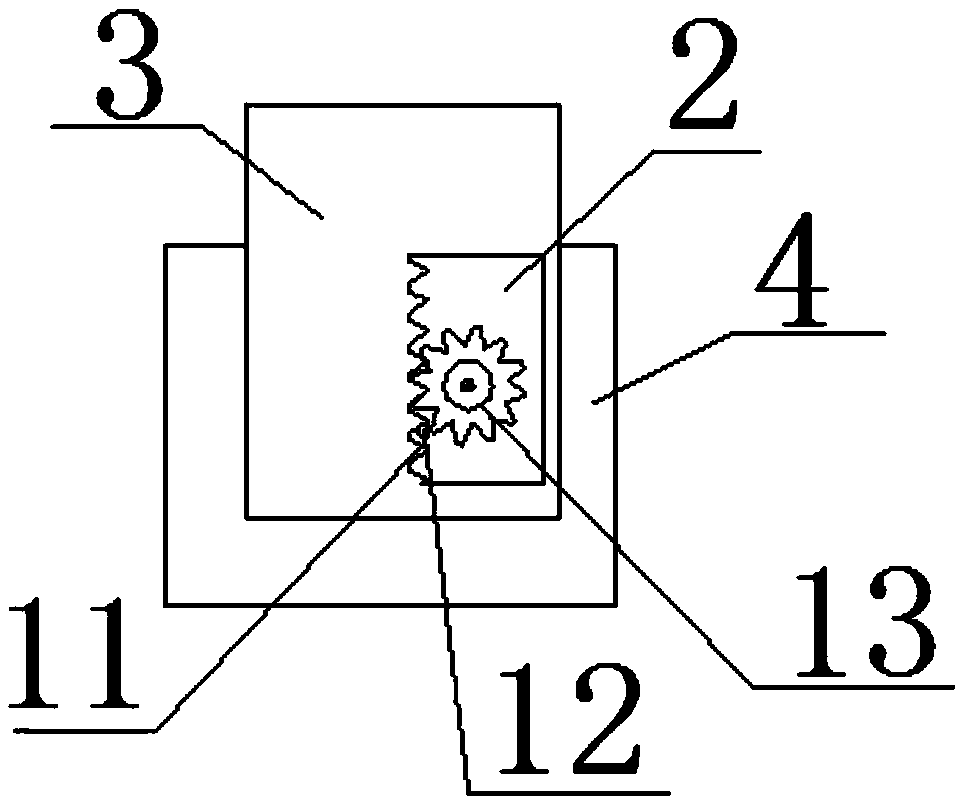

[0025] see Figure 1 to Figure 4 , the present invention provides a technical solution: a device for grinding plants, including a feed port 1, the inside of the feed port 1 is hollow, the outside of the feed port 1 is provided with a through hole 10, and the inside of the through hole 10 Through the limiting plate 3, the bottom end of the limiting plate 3 is provided with a limiting groove 2, the inner wall side of the limiting groove 2 is fixed with a wave block 11, the bottom end of the limiting plate 3 is provided with a fixed column 4, and the surface of the fixed column 4 Corresponding to the side of the wave block 11, the roller 13 is fixed by bolts, the limit plate 3 is engaged with the roller 13 through the wave block 11, the top of the limit plate 3 is provided with a card slot 20, and the inside of the card slot 20 is penetrated by a vertical rod 12 , a connection spring 15 is fixed between the vertical bar 12 and the slot 20, the limit plate 3 passes through the ver...

Embodiment 2

[0027] see Figure 1 to Figure 7 , the present invention provides a technical solution: a device for grinding plants, including a feed port 1, the inside of the feed port 1 is hollow, the outside of the feed port 1 is provided with a through hole 10, and the inside of the through hole 10 Through the limiting plate 3, the bottom end of the limiting plate 3 is provided with a limiting groove 2, the inner wall side of the limiting groove 2 is fixed with a wave block 11, the bottom end of the limiting plate 3 is provided with a fixed column 4, and the surface of the fixed column 4 Corresponding to the side of the wave block 11, the roller 13 is fixed by bolts, the limit plate 3 is engaged with the roller 13 through the wave block 11, the top of the limit plate 3 is provided with a card slot 20, and the inside of the card slot 20 is penetrated by a vertical rod 12 , a connection spring 15 is fixed between the vertical bar 12 and the slot 20, the limit plate 3 passes through the ver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com