Steaming and roasting combined machine

A combination machine, steaming and baking technology, applied in the field of steaming and baking combination machines, can solve the problems of limited device functions, achieve the effects of ensuring stability, ensuring independence, and improving use efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

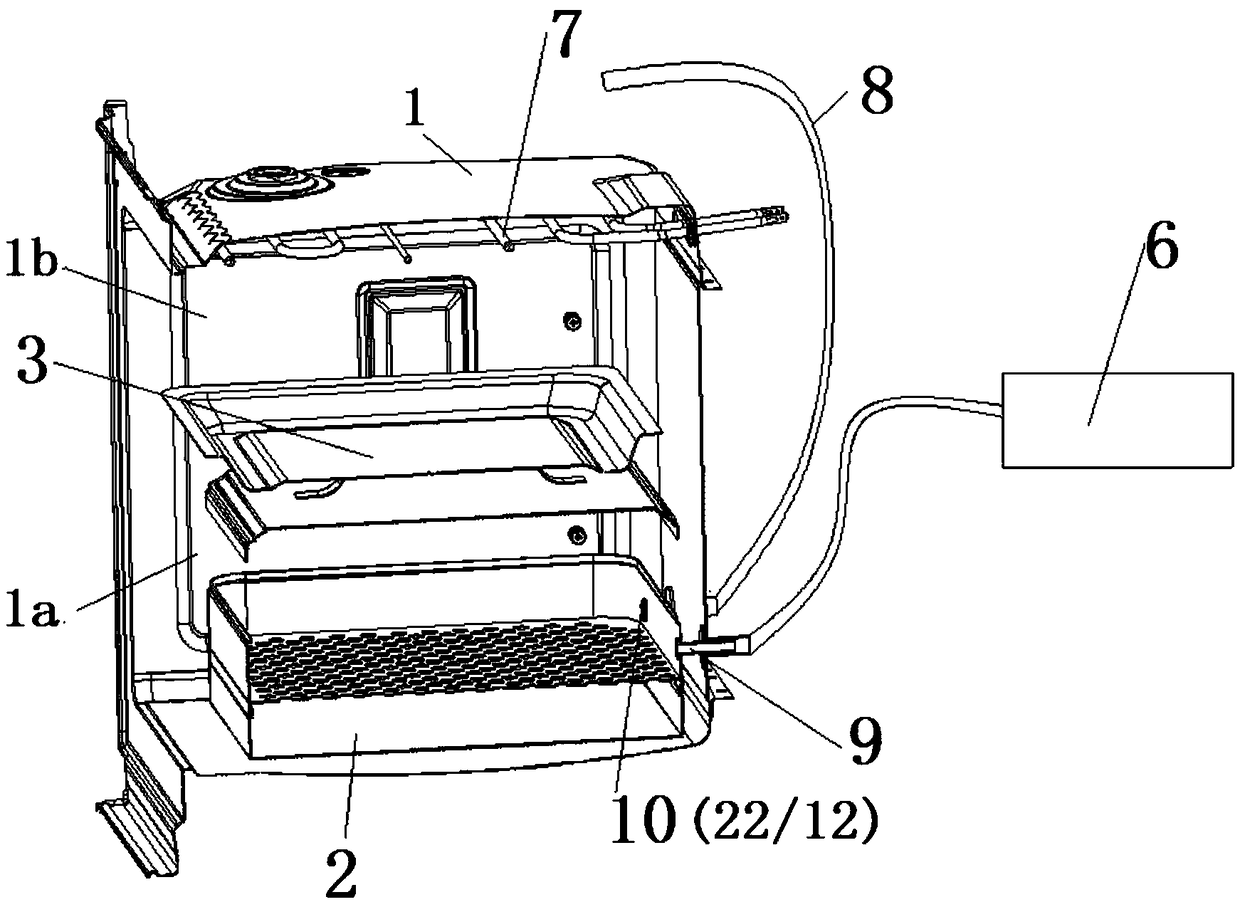

[0046] This embodiment provides a combination steaming and baking machine, such as figure 1 As shown, it includes: a housing 1, which is provided with a barbecue area 1b and a steaming area 1a, and the side wall of the housing is provided with a steam inflow hole for steam to flow in and a steam outflow hole for the steam in the accommodating chamber to flow out 11. The container 2 is arranged inside the steaming area, and the container is provided with a steam inlet 21 for steam to enter, and a steam outlet 22 for steam to flow out, and the steam inlet and the steam outlet are connected with each other. The steam inflow hole and the steam outflow hole are arranged oppositely; the grill pan 3 is set inside the grilling area 1b, and a heat pipe 7 is arranged in the housing corresponding to the grill pan to align with the grill pan. Grill the ingredients inside the grill pan. The steam inlet hole on the vessel is provided with a steam inlet pipe, and the end of the steam inlet ...

Embodiment 2

[0066] This embodiment is made on the basis of Embodiment 1. The difference between this embodiment and Embodiment 1 is that this embodiment provides another arrangement of the steam inlet pipe and the steam outlet pipe,

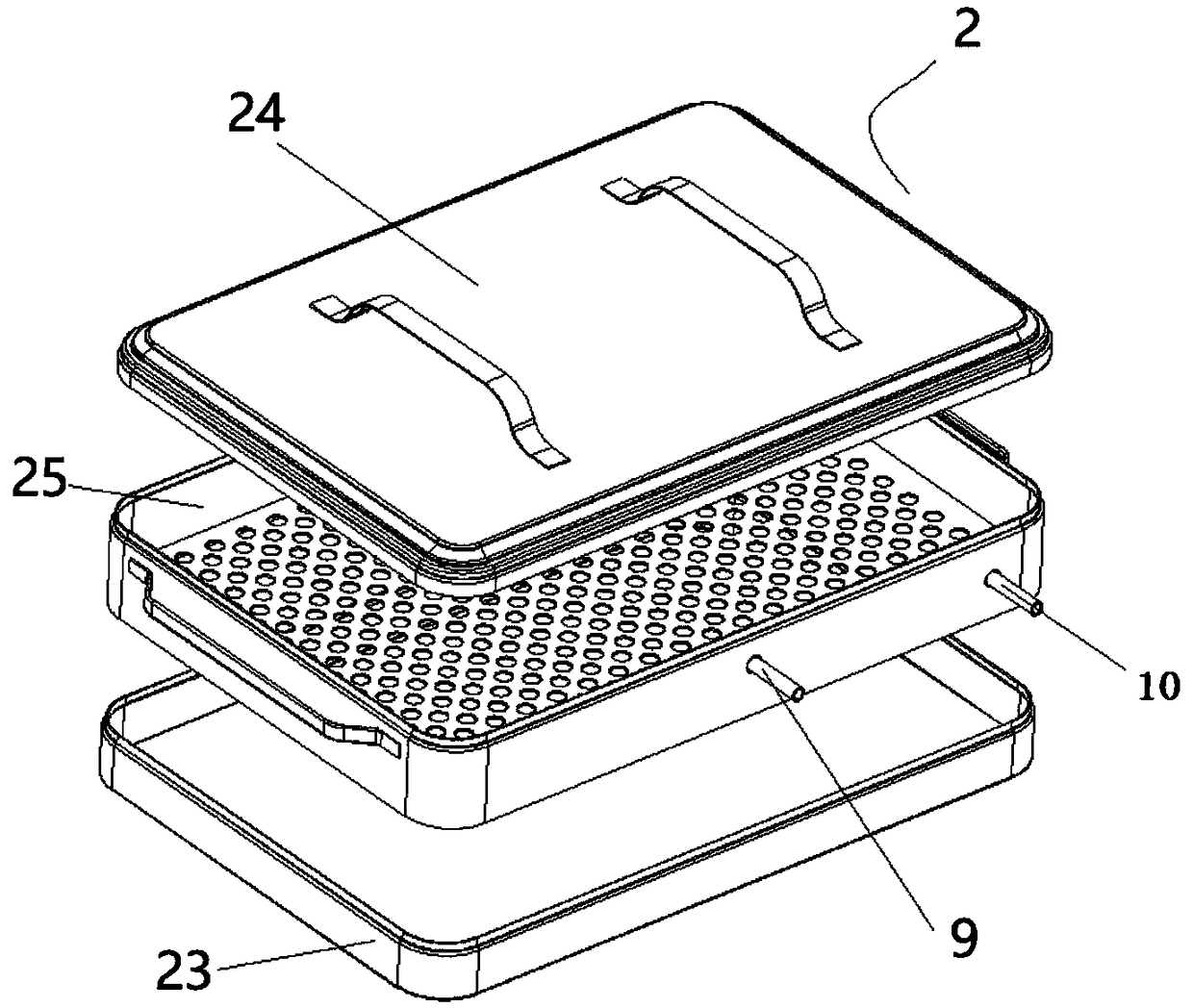

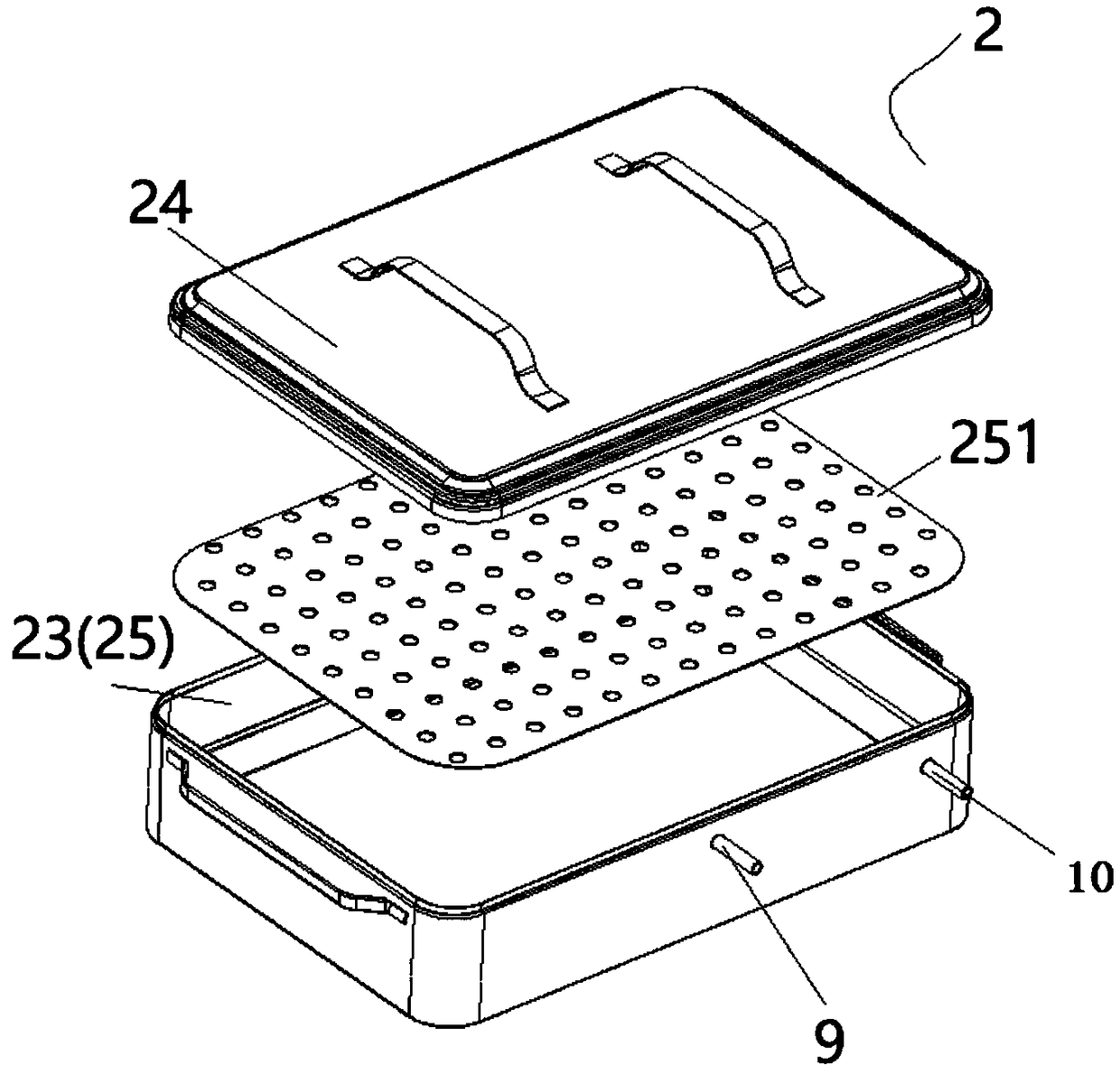

[0067] Such as Figure 5-7 As shown, the steam inlet pipe and the steam outlet pipe are fixedly arranged on the casing, the steam inlet pipe corresponds to the steam inlet hole 21 , and the steam outlet pipe 10 corresponds to the steam outlet hole 22 . When assembling, the steam inlet 21 and the steam outlet 22 of the container are aligned with the steam inlet pipe 9 and the steam outlet pipe 10 respectively. Thus, the steam inlet pipe 9 is inserted into the steam inlet hole 21 , and the steam outlet pipe 10 is inserted into the steam outlet hole 22 .

[0068] Simultaneously, in order to ensure the airtightness between the steam inlet pipe 9 and the steam inlet hole 21, between the steam outlet pipe 10 and the steam outlet hole 22, as Figure 7 As shown, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com