A kind of isomerization catalyst preparation method with MFI structure molecular sieve as carrier

A molecular sieve and catalyst technology, applied in the field of isomerization catalyst preparation, can solve problems such as difficulty in controlling the loading position of metal components, achieve high activity and isomer yield, high micropore volume and acid content, and reduce damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

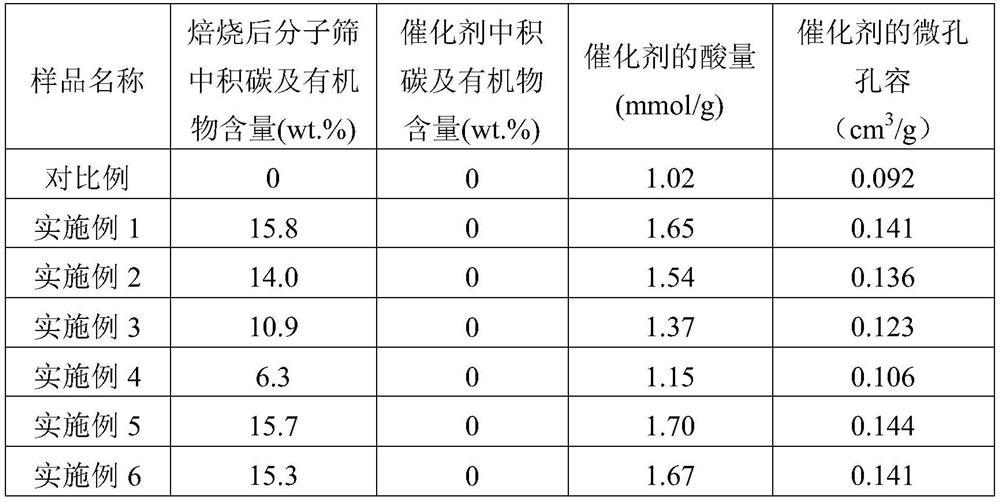

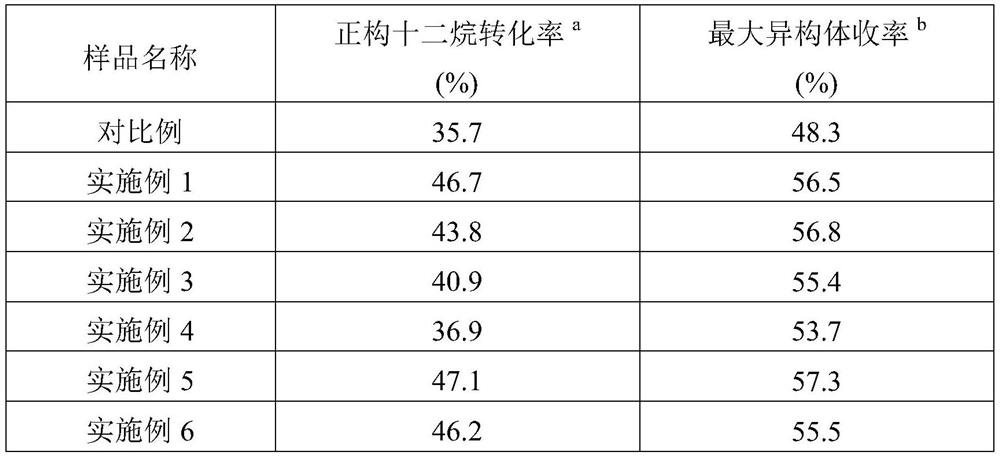

Embodiment 1

[0041] 20g of the same ZSM-5 molecular sieve powder as the comparative example (template content is 17.3wt.% of the molecular sieve weight) is placed in a quartz tube, and in an air atmosphere, the temperature is raised to 150°C at 5°C / min, at this temperature Calcined for 4 hours, then naturally cooled to room temperature to obtain the treated ZSM-5 molecular sieve carrier, the content of carbon deposits and organic matter in the molecular sieve carrier was 15.8wt.%. With 5.0mL containing Pt 0.001g / mL of H 2 PtCl 6 The solution impregnates 5 g of the above-mentioned molecular sieve carrier. The impregnated sample was dried at 120°C for 2h, and then reduced in a hydrogen atmosphere at 300°C for 4h to obtain a 0.5wt.% Pt / ZSM-5 catalyst. The content of carbon deposition and organic matter in the catalyst is 0, the acid content is 1.65mmol / g, and the micropore volume is 0.141cm 3 / g. See Table 1 for the characterization results of carbon deposition and organic content in the ...

Embodiment 2

[0043] The former powder of Cr-ZSM-5 molecular sieve that 20g contains template (template content is 17.8wt.% of molecular sieve weight, and the content of Cr is 0.9wt.%) is placed in quartz tube, in air atmosphere, 5 ℃ / The temperature was raised to 230° C. at this temperature for 12 hours, and then naturally cooled to room temperature to obtain the treated Cr-ZSM-5 molecular sieve carrier. The content of carbon deposits and organic matter in the molecular sieve carrier was 14.0wt.%. With 5.0mL containing Pt 0.001g / mL of H 2 PtCl 6 The solution impregnates 5 g of the above-mentioned molecular sieve carrier. The impregnated sample was dried at 120°C for 2h, and then reduced in a hydrogen atmosphere at 400°C for 6h to obtain a 0.5wt.% Pt / Cr-ZSM-5 catalyst. The content of carbon deposition and organic matter in the catalyst is 0, the acid content is 1.54mmol / g, and the micropore volume is 0.136cm 3 / g. See Table 1 for the characterization results of carbon deposition and org...

Embodiment 3

[0045] 20g of Co-ZSM-5 molecular sieve powder containing template (template content is 17.5wt.% of molecular sieve weight, Co content is 1.2wt.%) is placed in quartz tube, in air atmosphere, 5 ℃ / Min was raised to 300°C, calcined at this temperature for 2 hours, and then naturally cooled to room temperature to obtain the treated Co-ZSM-5 molecular sieve carrier, the content of carbon deposits and organic matter in the molecular sieve carrier was 10.9wt.%. With 5.0mL containing Pt 0.001g / mL of H 2 PtCl 6 The solution impregnates 5 g of the above-mentioned molecular sieve carrier. The impregnated sample was dried at 120°C for 2h, and then reduced at 400°C for 6h in a hydrogen atmosphere to obtain a 0.5wt.% Pt / Co-ZSM-5 catalyst. The content of carbon deposition and organic matter in the catalyst is 0, the acid content is 1.37mmol / g, and the micropore volume is 0.123cm 3 / g. See Table 1 for the characterization results of carbon deposition and organic content in the molecular ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com