A kind of preparation method of isomerization catalyst with ael structure molecular sieve as carrier

A molecular sieve and isomerization technology, applied in molecular sieve catalysts, catalyst activation/preparation, isomerization hydrocarbon production, etc., can solve the problems of affecting catalyst performance, reducing the number of micropores, increasing strong acid sites, etc., to achieve high isomerization selectivity and isomer yield, reducing energy consumption, and the effect of high micropore volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

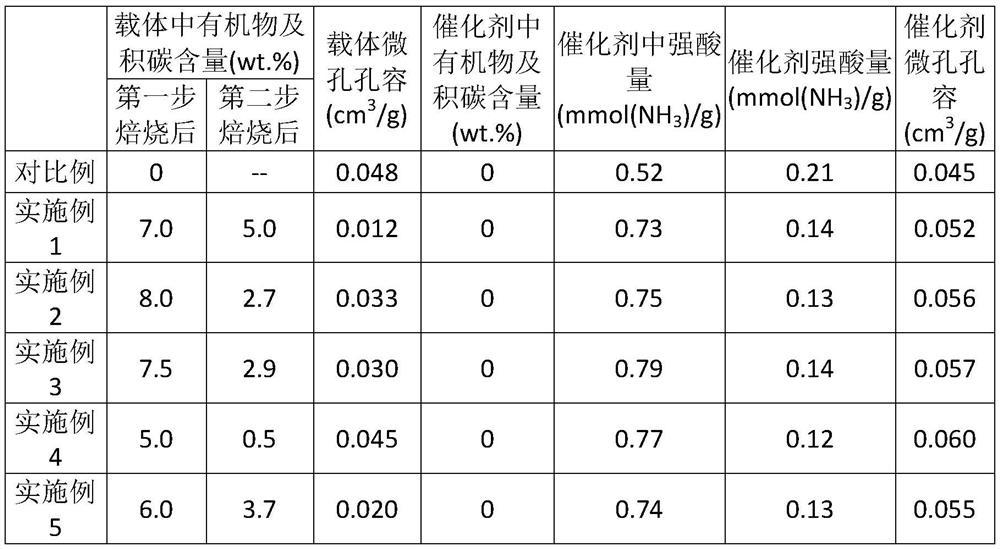

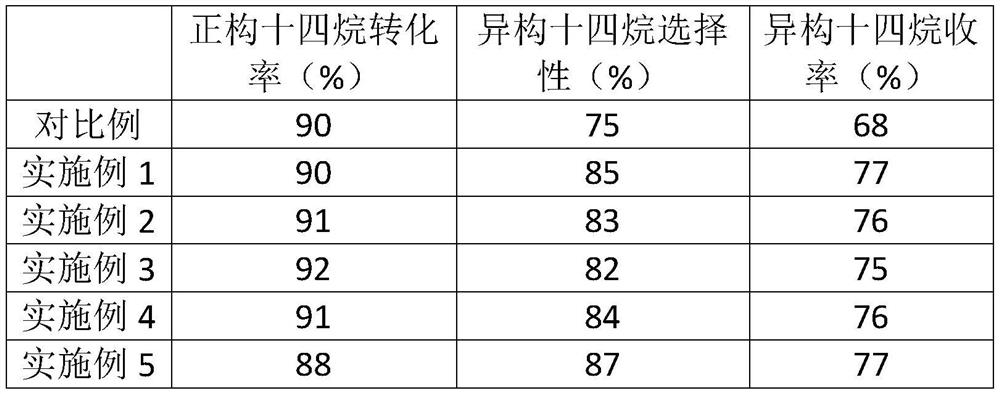

[0046] Get 120g of SAPO-11 molecular sieve former powder (same as the comparative example, Si content is 0.6wt.%) that contains di-n-propylamine template (content is 10wt.% of molecular sieve weight), roasting 12h under 210 ℃ of nitrogen atmospheres, after roasting Molecular sieve-loaded carbon and organic matter content is 7.0wt.%; then continue roasting for 6 hours at 250°C in an air atmosphere to obtain about 105g of SAPO-11 molecular sieve carrier with template agent partially removed, the molecular sieve-loaded volume carbon and organic matter content is 5.0wt. .%, micropore volume is 0.012cm 3 / g. With 5mL of H containing Pt 0.05g / mL 2 PtCl 6 The solution was impregnated with 50 g of the above carrier, dried naturally at 120° C. for 4 h, and reduced with hydrogen at 400° C. for 4 h to prepare a 0.5 wt.% Pt / SAPO-11 catalyst. The content of carbon deposits and organic matter in the catalyst is 0, the amount of medium-strong acid is 0.73mmol / g, the amount of strong acid ...

Embodiment 2

[0048] Get 120g MgAPO-11 molecular sieve former powder (Mg content is 0.05wt.%) that contains di-n-propylamine templating agent (content is 12wt.% of molecular sieve weight), 220 ℃ of roasting 6h under nitrogen atmosphere, after roasting, molecular sieve loads bulk carbon and The content of organic matter is 8.0wt.%; and then roasted at 350°C for 12 hours in an air atmosphere to obtain about 105g of MgAPO-11 molecular sieve carrier from which the template agent has been partially removed. Capacity is 0.033cm 3 / g. With 5mL of H containing Pt0.05g / mL 2 PtCl 6 The solution was impregnated with 50 g of the above carrier, dried naturally at 120° C. for 4 h, and reduced with hydrogen at 400° C. for 2 h to prepare a 0.5 wt.% Pt / MgAPO-11 catalyst. The content of carbon deposits and organic matter in the catalyst is 0, the amount of medium-strong acid is 0.75mmol / g, the amount of strong acid is 0.13mmol / g, and the volume of micropores is 0.056cm 3 / g. See Table 1 for the characte...

Embodiment 3

[0050] Get 120g ZnAPO-11 molecular sieve former powder (Zn content is 1wt.%) that contains diisopropylamine templating agent (content is 20wt.% of molecular sieve weight), 250 ℃ of roasting 2h under nitrogen atmosphere, after roasting, molecular sieve loads bulk carbon and organic matter content of 7.5wt.%; and then roasted at 200°C for 12h in an ozone atmosphere to obtain about 105g of ZnAPO-11 molecular sieve carrier from which the template was partially removed. 0.031cm 3 / g. With 5mL of H containing Pt0.05g / mL 2 PtCl 6 The solution was impregnated with 50 g of the above carrier, dried naturally at 120° C. for 4 h, and reduced with hydrogen at 200° C. for 8 h to obtain a 0.5 wt.% Pt / ZnAPO-11 catalyst. The content of carbon deposits and organic matter in the catalyst is 0, the amount of medium-strong acid is 0.79mmol / g, the amount of strong acid is 0.14mmol / g, and the volume of micropores is 0.057cm 3 / g. See Table 1 for the characterization results of carbon deposits, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com