Preparation method of shape-selective isomerization catalyst based on MTT type structure molecular sieve

A molecular sieve and catalyst technology, applied in the field of preparation of shape-selective isomerization catalysts, can solve the problems of reduced catalyst activity and isomer selectivity, achieve high activity and isomer yield, improve mass transfer, and shorten pores effect of depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

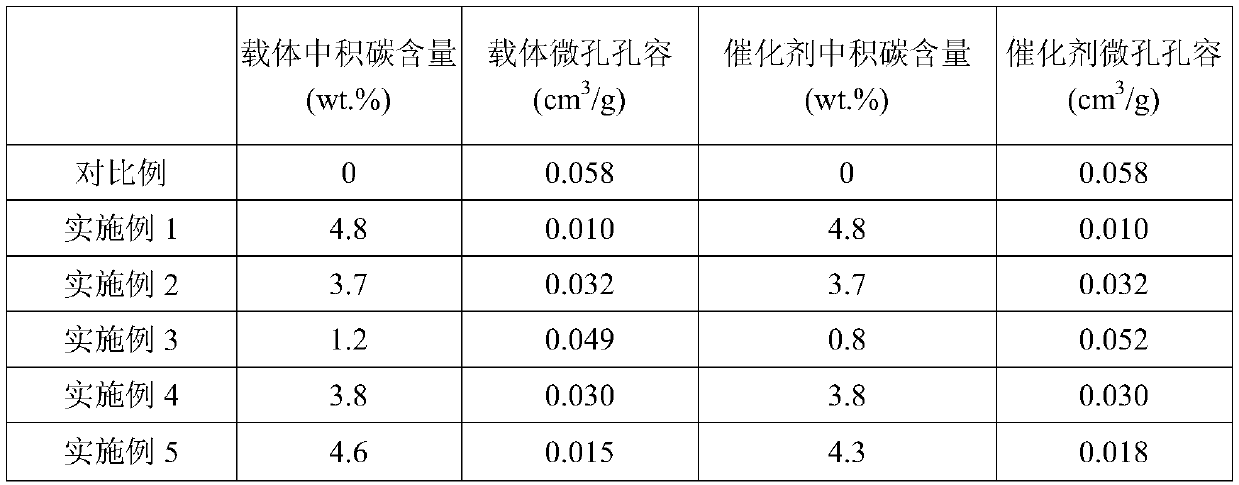

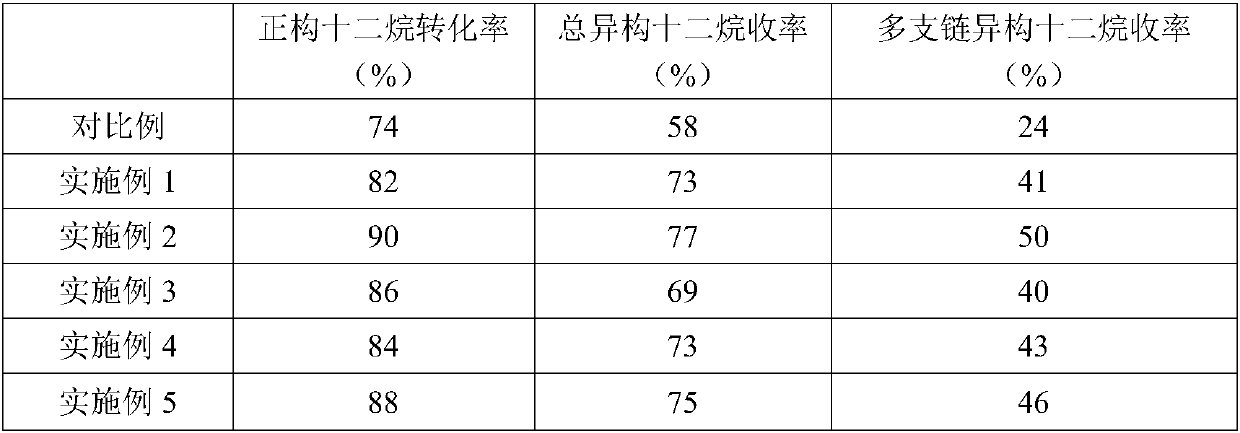

Embodiment 1

[0036] Put 20 g of ZSM-23 molecular sieve raw powder containing dimethylamine template (6% by weight of the molecular sieve) into a quartz tube, bake at 250° C. for 4 hours in an air atmosphere, and cool naturally to room temperature to obtain a microporous channel substrate. Carbon partially filled ZSM-23 molecular sieve carrier, the carbon content in the molecular sieve carrier is 4.8%, and the micropore volume is 0.010cm 3 / g. With 5.0mL containing Pt0.001g / mL of H 2 PtCl 6 The solution impregnates 5 g of the above-mentioned molecular sieve carrier. The impregnated sample was dried at 120°C for 2h, and at 200°C, the hydrogen flow rate was controlled at 5mL / min / g 催化剂 , and reduced for 4h to obtain 0.5wt.% Pt / ZSM-23 catalyst. The carbon content in the catalyst is 4.8%, and the micropore volume is 0.010cm 3 / g. The characterization results of catalyst carbon content and micropore volume are shown in Table 1, and the evaluation results of catalytic reaction are shown in T...

Embodiment 2

[0038] Put 20 g of ZSM-23 molecular sieve raw powder containing dimethylamine template (6% by weight of the molecular sieve) in a quartz tube, bake at 320 ° C for 4 h in a nitrogen atmosphere, and cool naturally to room temperature to obtain a microporous channel substrate. ZSM-23 molecular sieve carrier partially filled with carbon, the carbon content in the molecular sieve carrier is 3.7%, and the micropore volume is 0.032cm 3 / g. With 5.0mL containing Pt0.001g / mL of H 2 PtCl 6 The solution impregnates 5 g of the above-mentioned molecular sieve carrier. The impregnated sample was dried at 120°C for 2 hours, and at 300°C, the hydrogen flow rate was controlled at 20mL / min / g 催化剂 , and reduced for 4h to obtain 0.5wt.% Pt / ZSM-23 catalyst. The carbon content in the catalyst is 3.7%, and the micropore volume is 0.032cm 3 / g. The characterization results of catalyst carbon content and micropore volume are shown in Table 1, and the evaluation results of catalytic reaction are s...

Embodiment 3

[0040] Put 20 g of ZSM-23 molecular sieve raw powder containing dimethylamine template (6% by weight of the molecular sieve) in a quartz tube, bake at 400° C. for 4 hours in an air atmosphere, and cool naturally to room temperature to obtain a microporous channel substrate. ZSM-23 molecular sieve carrier partially filled with carbon, the carbon content in the molecular sieve carrier is 1.2%, and the micropore volume is 0.049cm 3 / g. With 5.0mL containing Pt0.001g / mL of H 2 PtCl 6 The solution impregnates 5 g of the above-mentioned molecular sieve carrier. The impregnated sample was dried at 120°C for 2 hours, and at 400°C, the hydrogen flow rate was controlled at 40mL / min / g 催化剂 , and reduced for 4h to obtain 0.5wt.% Pt / ZSM-23 catalyst. The carbon content in the catalyst is 0.8%, and the micropore volume is 0.052cm 3 / g. The characterization results of catalyst carbon content and micropore volume are shown in Table 1, and the evaluation results of catalytic reaction are s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com