Small lifting equipment for building construction

A technology for building construction and lifting equipment, which is applied in mechanical equipment, supporting machines, machines/stands, etc., can solve the problems of narrow application range and limited height of the device, and achieves a stable, reliable fixation, and prevents sliding and falling off. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

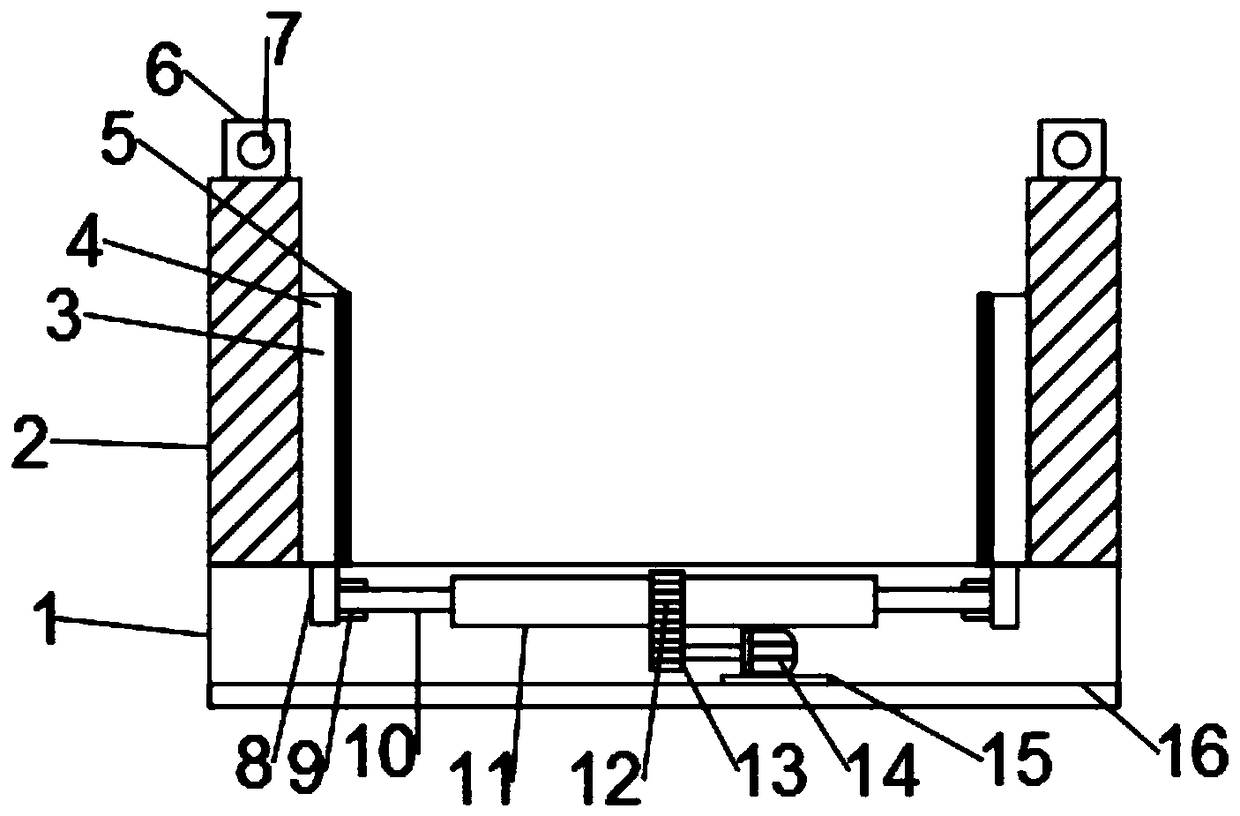

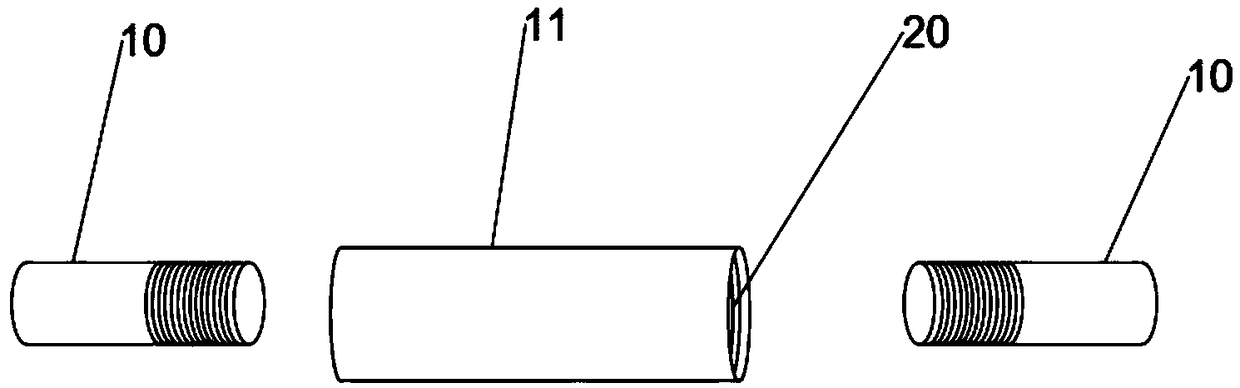

[0027] See figure 1 , figure 2 and Figure 5 In the embodiment of the present invention, a small-sized lifting equipment for building construction includes a bottom plate 1, a protective wall 2 and a fixed support 6. The top peripheral side of the bottom plate 1 is provided with a fixedly connected protective wall 2 for protection, To prevent items from falling, a fixed support 6 is provided in the middle of the top of the protective wall 2, and a first through hole 7 is provided on the fixed support 6, which is fixed by inserting a steel wire into the first through hole 7 to facilitate Raise the device.

[0028] The top of the bottom plate 1 is provided with a groove 19, the left and right ends of the inside of the groove 19 are symmetrically provided with slidingly connected sliders 8, the upper end of the slider 8 is fixedly connected with a baffle 4, the width of the baffle 4 Greater than the width of the groove 19, the clamping device 3 includes a baffle 4 and a rubber lay...

Embodiment 2

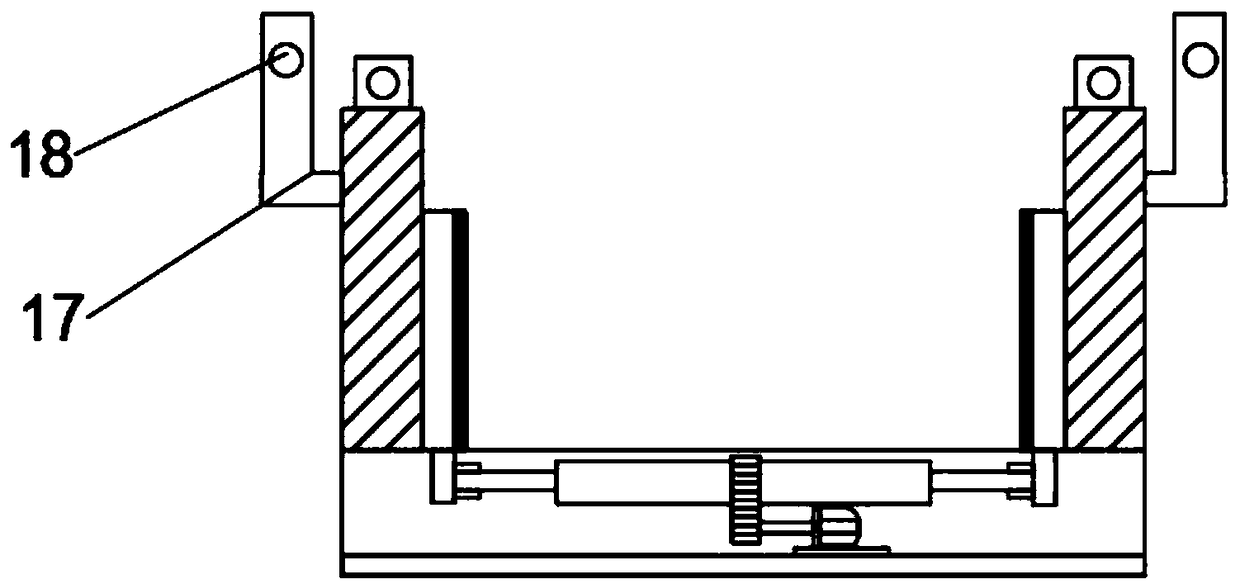

[0036] See figure 2 , image 3 and Figure 5 The difference between embodiment 2 and embodiment 1 is that it also includes an L rod 17 and a second through hole 18. The transverse part of the L rod 17 is fixedly connected to the upper outer surface of the protective wall 2, and the longitudinal part of the L rod 17 is arranged above There is a second through hole 18, and the steel wire rope is further connected with the second through hole 18 to play a role of secondary protection and make the device more stable when it is raised.

Embodiment 3

[0038] See figure 2 , Figure 4 and Figure 5 The difference between Embodiment 3 and Embodiment 2 is that it also includes a moving device 21, which is fixedly arranged at the bottom four corners of the bottom plate 1, and the moving device 21 includes a third buffer layer 22, a hydraulic cylinder 23, and a supporting leg 24 and a roller 25. A third buffer layer 22 is provided above the moving device 21, a hydraulic cylinder 23 is provided at the lower end of the third buffer layer 22, and a roller 25 is provided below the telescopic end of the hydraulic cylinder 23. A support leg 24 is provided on the outside of the telescopic end of the cylinder 23. The support leg 24 has an internal hollow structure and can accommodate the roller 25. The device can be moved by the moving device 21, and the height can be adjusted by adjusting the hydraulic cylinder 23, and the fixing is reliable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com