Pump dispenser

A dispenser, to-be-distributed technology, applied in spraying devices, single handheld devices, etc., can solve problems such as product leakage, plunger rising, lower locking thread loosening, etc., to achieve high rotation safety and material saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] First, describe the general characteristics of the pump.

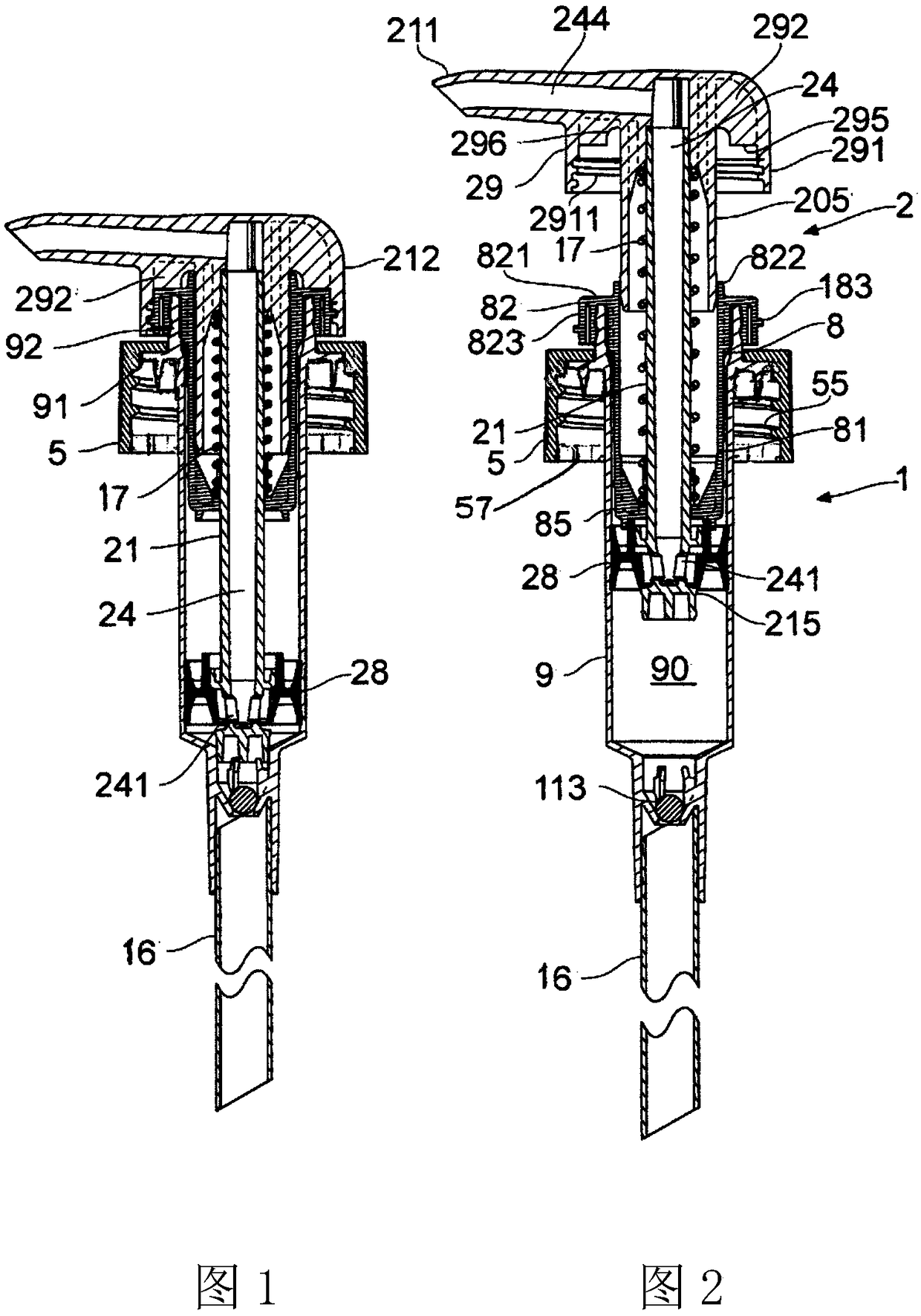

[0054] figure 1 with 2 A movable nozzle pump with down-locking capability is shown: a pump that uses it to implement this proposal.

[0055] The pump has a body 1 and a plunger 2. The closure cap 5 with internal threads 55 is used to mount the pump on the neck of the container.

[0056] The body 1 includes a cylindrical part 9 and a body insertion part 8. The cylindrical member 9 has a top annular rim 92 protruding upward through the hole in the cover 5 and a radial flange 91 engaged below the cover, so that the cover 5 clamps the flange 91 downward against the neck of the container during use. top. The main lower part of the cylindrical member 9 protrudes axially downward into the interior of the container, converging at its bottom end to define an inlet valve seat for the inlet valve 113 (for example, a ball valve) and a socket for the dip tube 16.

[0057] The body insertion part 8 is also generally cylindrical in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com