Anti-blocking punching device

A hole opener and anti-blocking technology, used in drilling/drilling equipment, drilling tool accessories, transportation and packaging, etc., can solve the problems of large hole opening resistance, easy breakage, and difficult cleaning, and improve hole opening efficiency. , The opening resistance is small, and the effect of reducing the resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

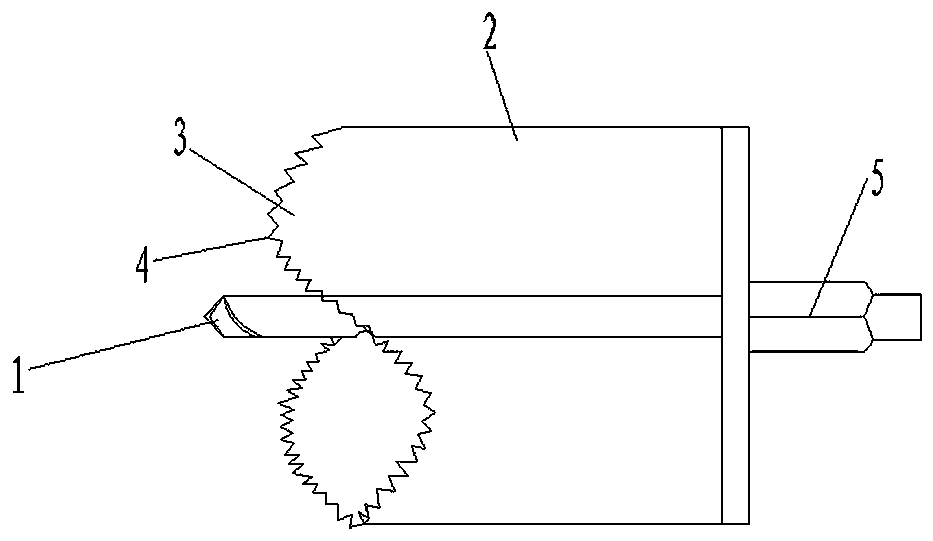

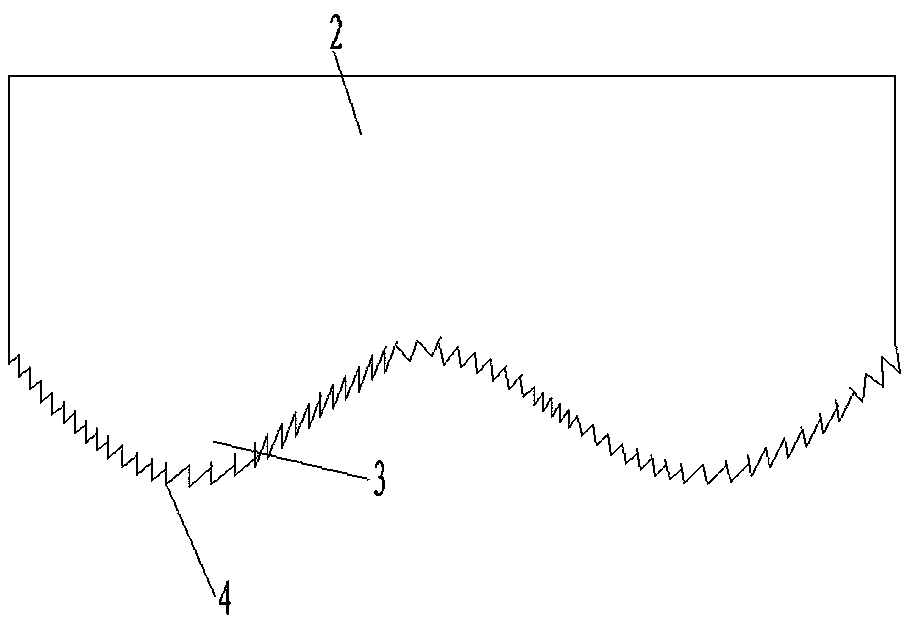

[0012] figure 1 , figure 2 Middle: center drill bit 1, hole sleeve 2, sawing edge 3, saw tooth 4, fixing piece 5.

[0013] The anti-blocking conversion hole opener includes a central drill bit 1 and a hole-piercing sleeve 2, the central drill bit 1 is fixedly connected to the hole-piercing sleeve 2, the central drill bit 1 is concentric with the hole-piercing sleeve 2, and the The center drill bit 1 protrudes outside the perforated column sleeve 2 . The purpose of this is to position first and then open the hole. The sawing edge 3 of the perforated column sleeve 2 is wavy, and the distance between adjacent wave crests is 1 / 3 to 1 / 2 of the circumference of the perforated column sleeve 2. Setting such a shape is to increase the opening The local acting pressure of the orifice. Improve hole opening efficiency and reduce resistance. Said saw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com