Flow guide non-return device

A technology of check device and valve plate, which is applied in the direction of valve device, control valve, function valve type, etc., and can solve problems such as oil stain adhesion, large adhesion force, and difficulty in opening the valve plate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

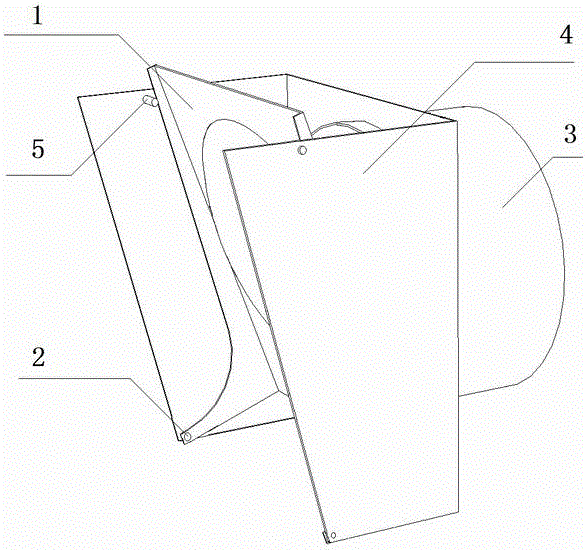

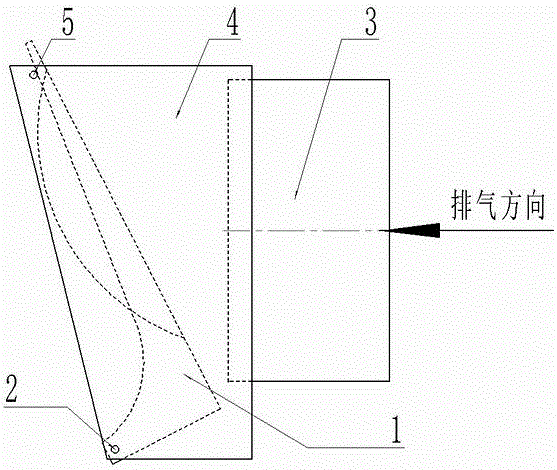

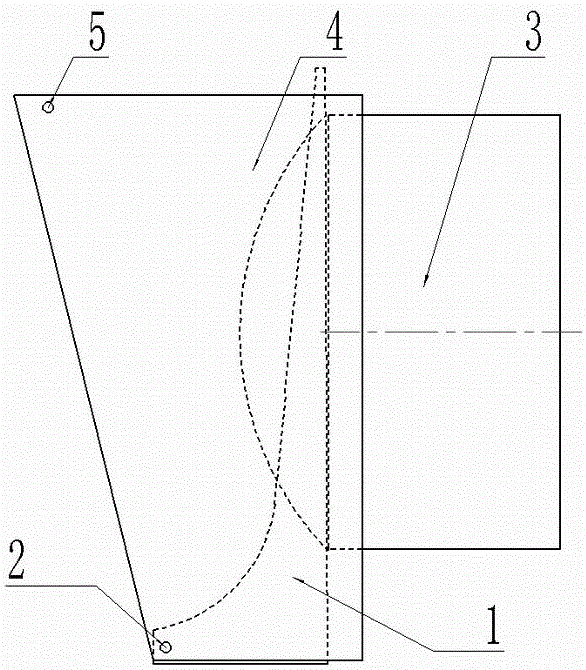

[0033] like figure 2 As shown, it is a diversion check device provided by the present invention. The range hood or exhaust fan is connected to the exhaust pipe. When working, the air flows through the exhaust pipe to push the valve plate to rotate around the axis of the hinge, and the limit device When the valve plate is opened to a fixed angle, it forms an upward exhaust channel with the exhaust pipe and the frame, guiding the airflow to discharge upward, which can effectively prevent the generation of air curtain.

[0034] The pot-shaped concave surface of the valve plate can adjust the angle of the wind when the angle of the valve plate changes, so as to maintain the wind resistance and facilitate the opening of the valve plate.

[0035] like image 3 As shown, when the range hood stops, the valve plate falls back around the hinge axis and rotates to reset under the action of gravity, and presses the valve plate against the end of the exhaust pipe to prevent smoke and odo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com