Haptic feedback module, preparation method thereof and touch control device thereof

A technology of tactile feedback and thickness direction, applied in mechanical mode conversion, piezoelectric devices/electrostrictive devices, instruments, etc., can solve the problem of no tactile feedback of piezoelectric units

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Such as figure 1 As shown, the touch device 100 includes a cover plate 20 and a plurality of tactile feedback modules 10 . The cover 20 defines a touch surface 21 for inputting touch operations. The tactile feedback module 10 is disposed on a side of the cover 20 away from the touch surface 21 . The touch control device 100 can be a mobile phone, a tablet computer, a smart wearable device (such as a smart watch) and the like.

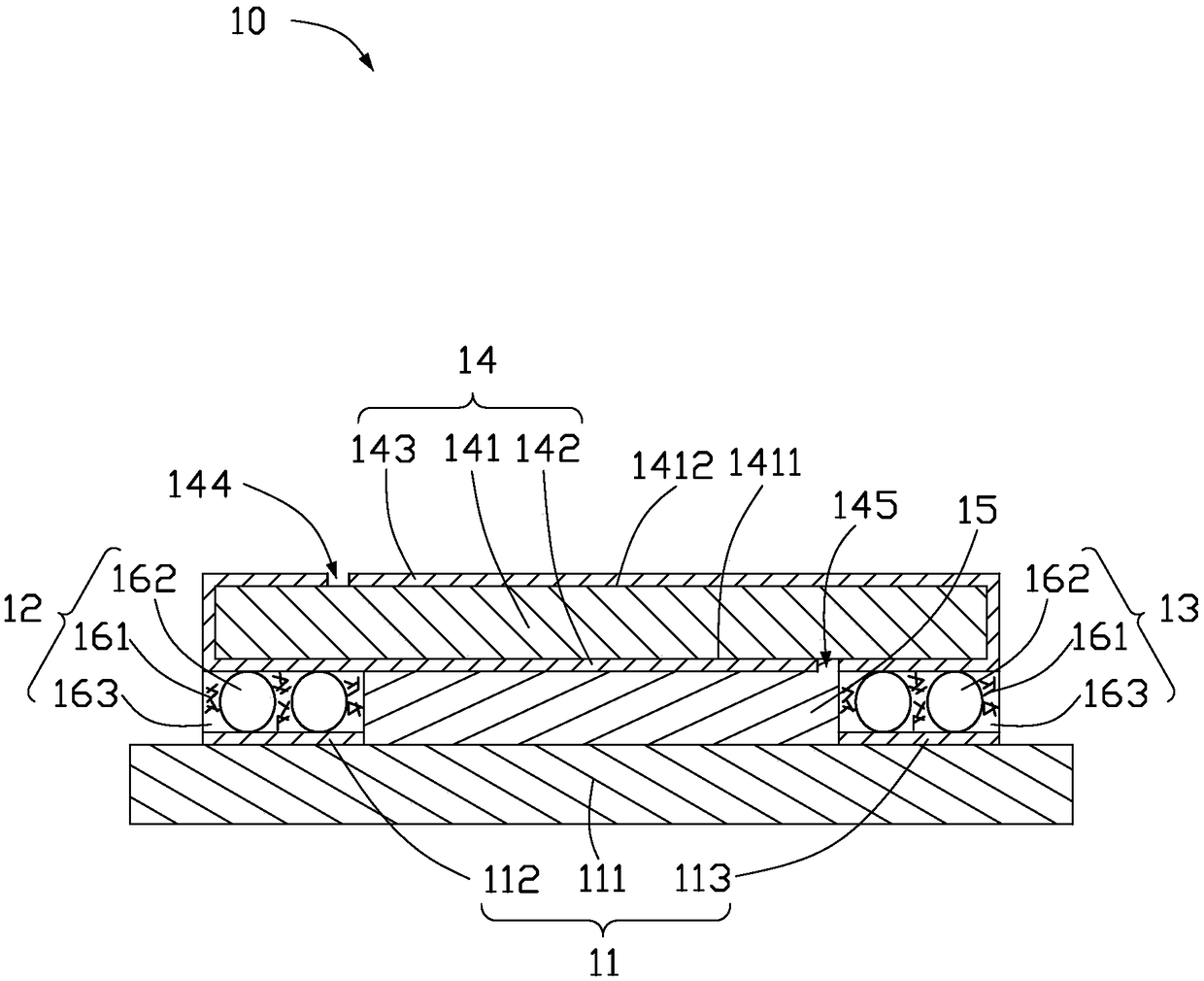

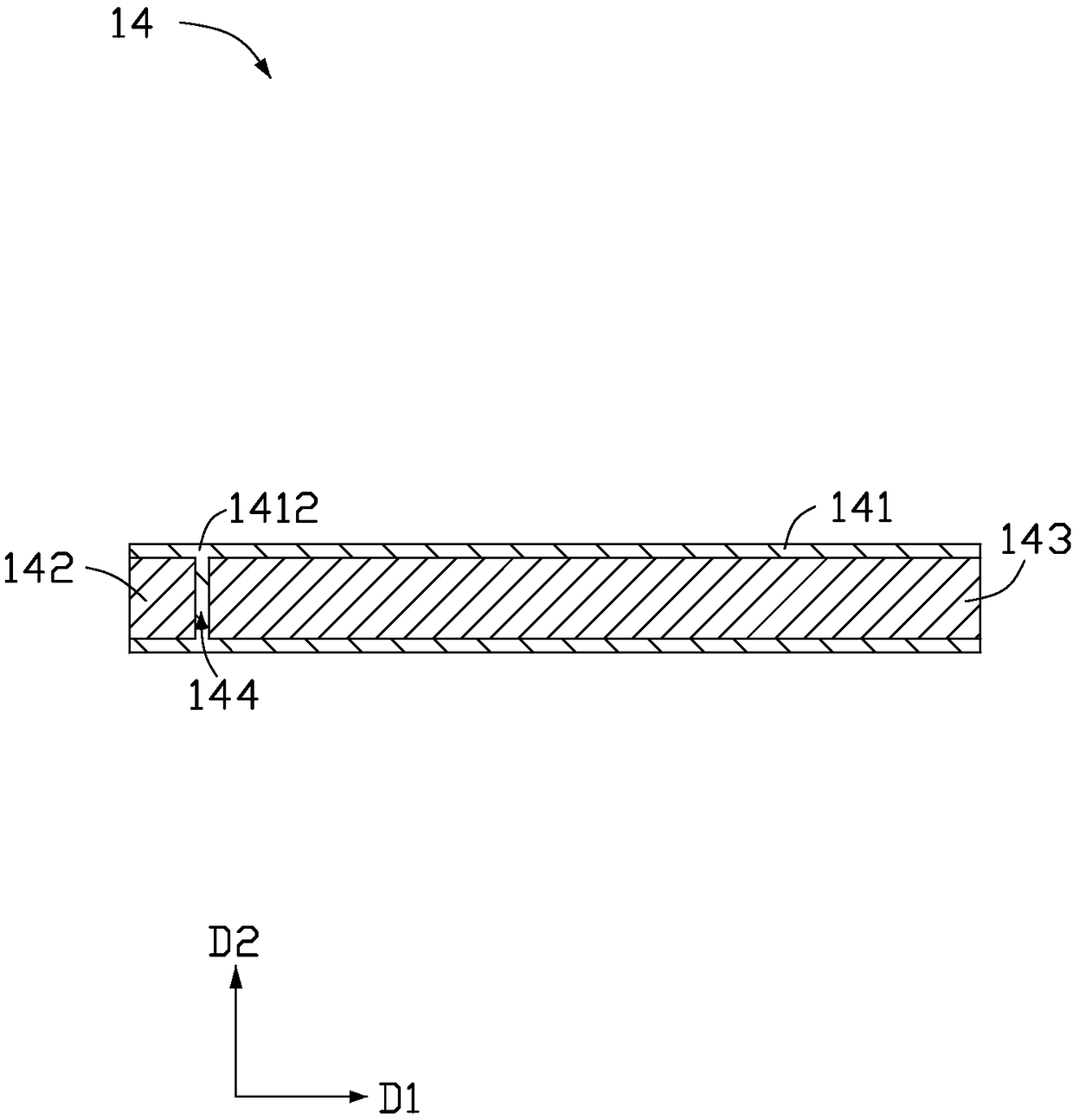

[0032] Such as figure 2 As shown, the tactile feedback module 10 includes a circuit board 11 , a first isotropic conductive film (ICF) 12 , a second isotropic conductive film 13 , a piezoelectric unit 14 and an insulating film 15 .

[0033] Such as figure 2 As shown, the circuit board 11 includes a substrate 111 , a first connection pad 112 and a second connection pad 113 . The first connection pads 112 and the second connection pads 113 are located on the same surface of the substrate 111 , and the first connection pads 112 and the second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com