Device for preventing arc discharge of metal contacts

A technology of metal contacts and thin films, applied in the field of sensors, can solve problems such as difficult application of sensors, and achieve the effects of preventing arcing, simple structure, and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

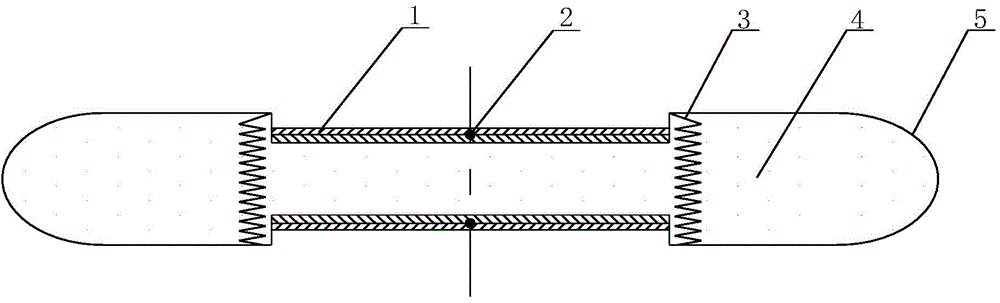

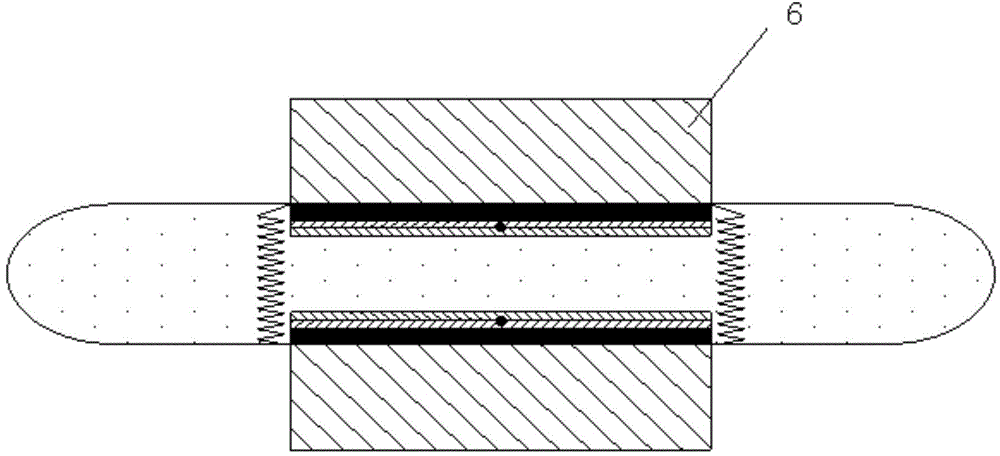

[0012] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0013] A device for preventing metal contacts from arcing, including a copper foil 1, a spring 3, and a film 5 composed of an upper copper foil and a lower copper foil, the upper copper foil and the lower copper foil clamp the film 5, the upper copper foil and the lower copper foil Welding is performed between the copper foils, and after welding, they are closely bonded to the film 5 to ensure the airtightness inside the film 5; the spring 3 is placed on both sides of the lower copper foil in the film 5.

[0014] The inside of the film 5 is filled with nitrogen gas.

[0015] The film 5 is made of a polytetrafluoroethylene film with a thickness of δ0.1.

[0016] The spring 3 is wound from carbon spring steel wire.

[0017] 1) Upper and lower copper foil

[0018] Copper foil 1 is composed of upper copper foil and lower copper foil. The upper and lower copper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com