A tensile performance testing device based on polymer rubber testing

A technology for tensile properties and testing devices, which is applied to measuring devices, applying stable tension/pressure to test material strength, and analyzing materials. Achieve perfect function and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

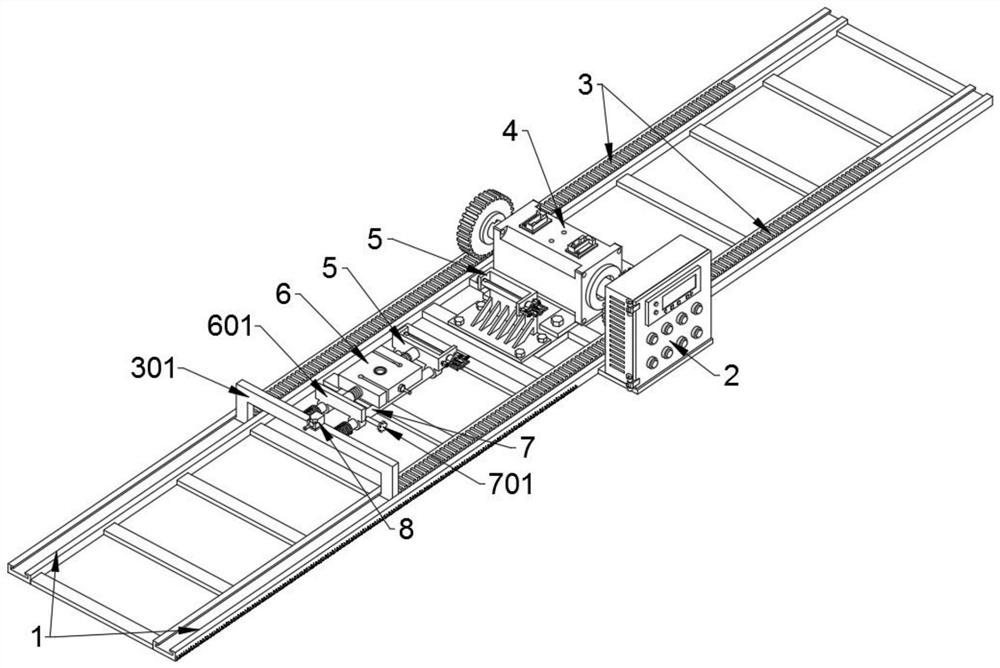

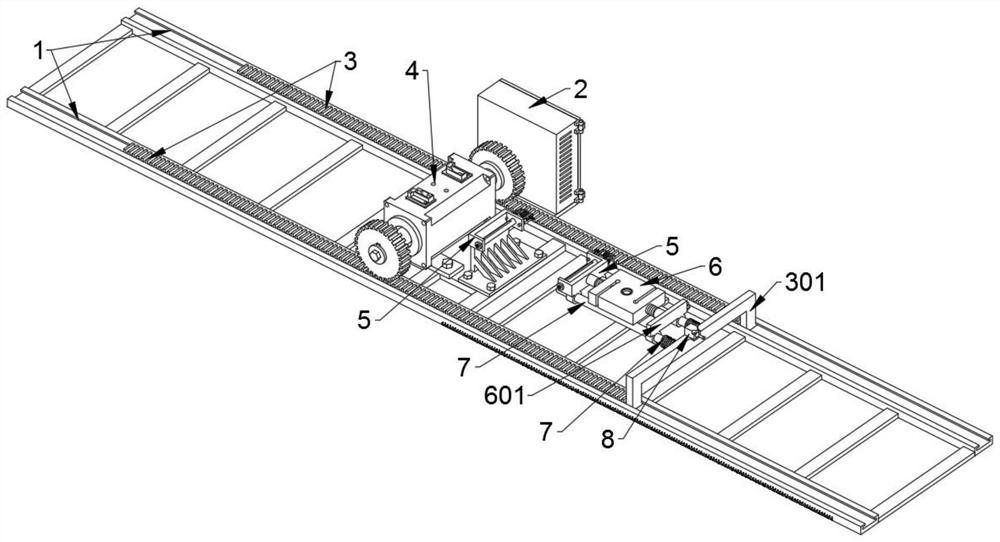

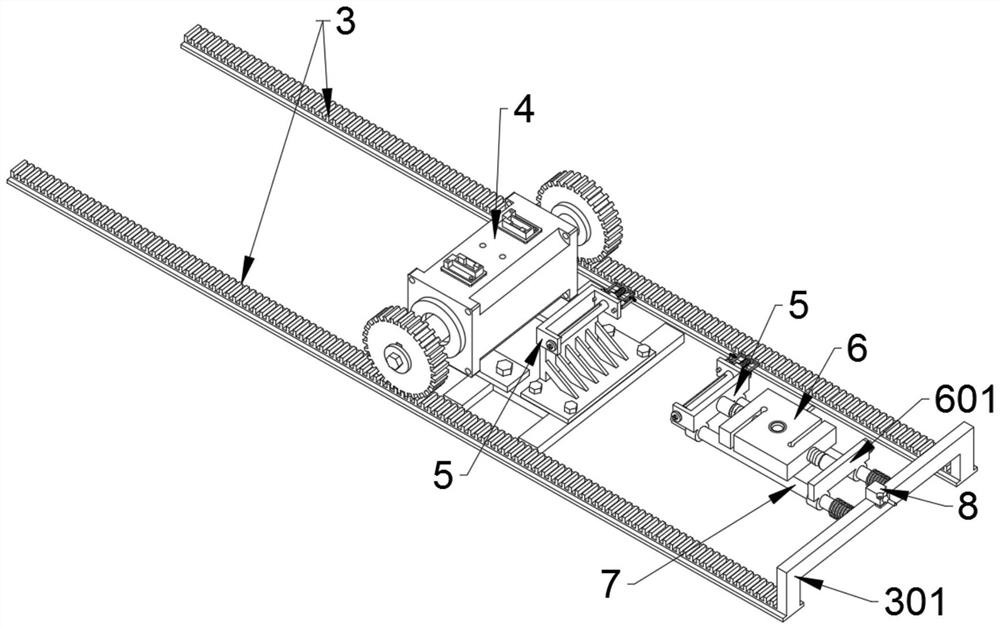

[0033] as attached figure 1 To attach Figure 10 Shown:

[0034] The present invention provides a tensile performance testing device based on polymer rubber testing, which includes a track groove 1, a control electric box 2, a rack 3, an installation frame 301, a double-outlet stepping motor 4, a support frame 5, and an S-type Tension sensor 6, sensor backing plate 601, positioning strut 7, limit rod 701, proximity switch 8, roll rod 9, headgear 901, pulling rod 902, insert frame 903, pull frame 904 and positioning strut 905; two places The track groove 1 is left and right symmetrically supported, and a double-outlet stepping motor 4 is installed in the middle of the space between the two track grooves 1, and the left and right ends of the double-outlet stepping motor 4 shafts are locked. There is a gear connected to the tight socket key; a row of scale marks is arranged on the outer wall of the first half of the track groove 1 at the two places; a proximity switch is instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com