Rotary oil spraying device for hardware fittings

A technology of oil spraying device and rotating device, which is applied in the direction of spraying device, etc., which can solve the problems of uneven coating and incomplete coating, and achieve the effects of convenient use, preventing incomplete spraying and reducing dead angle of spraying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

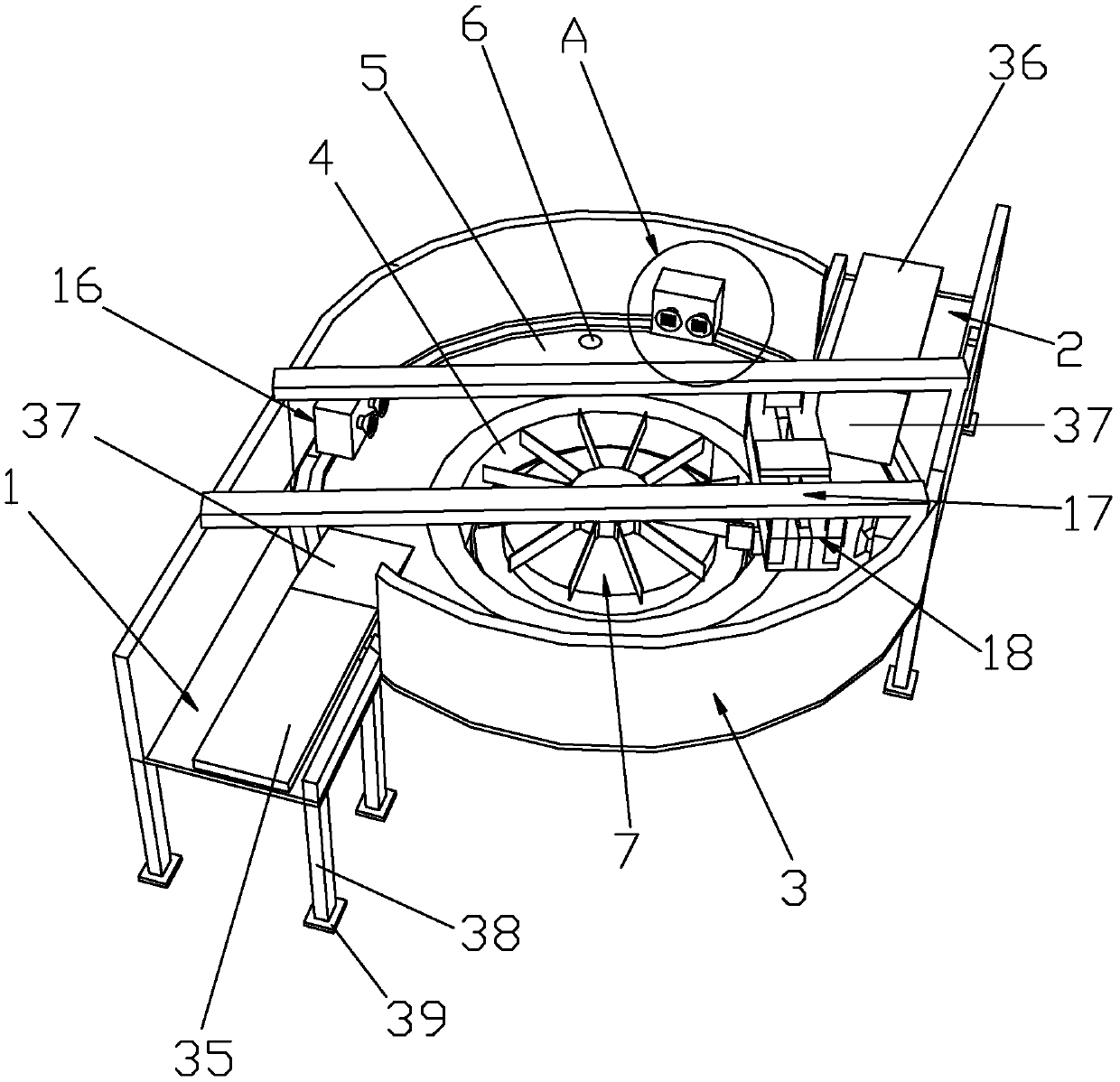

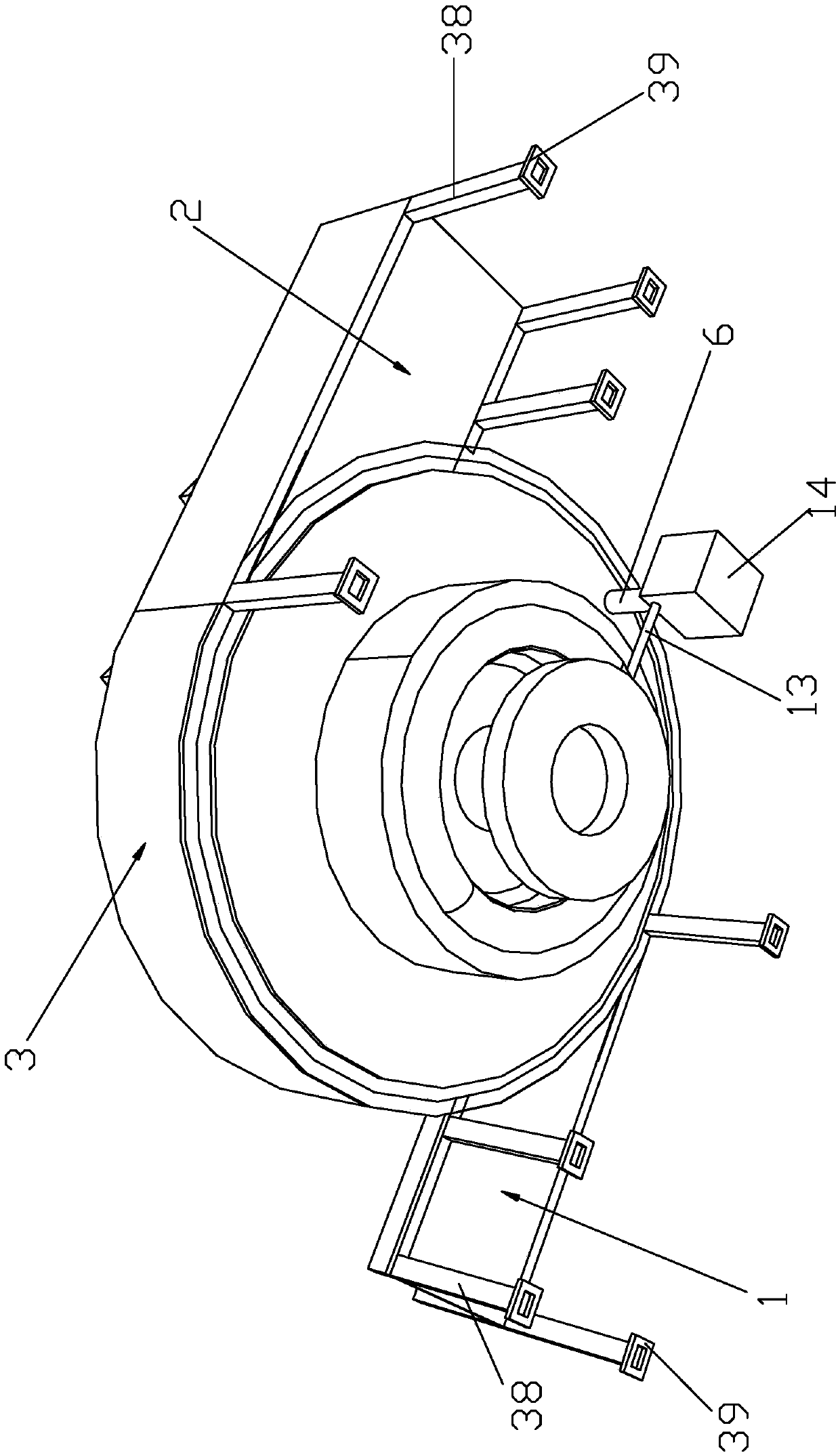

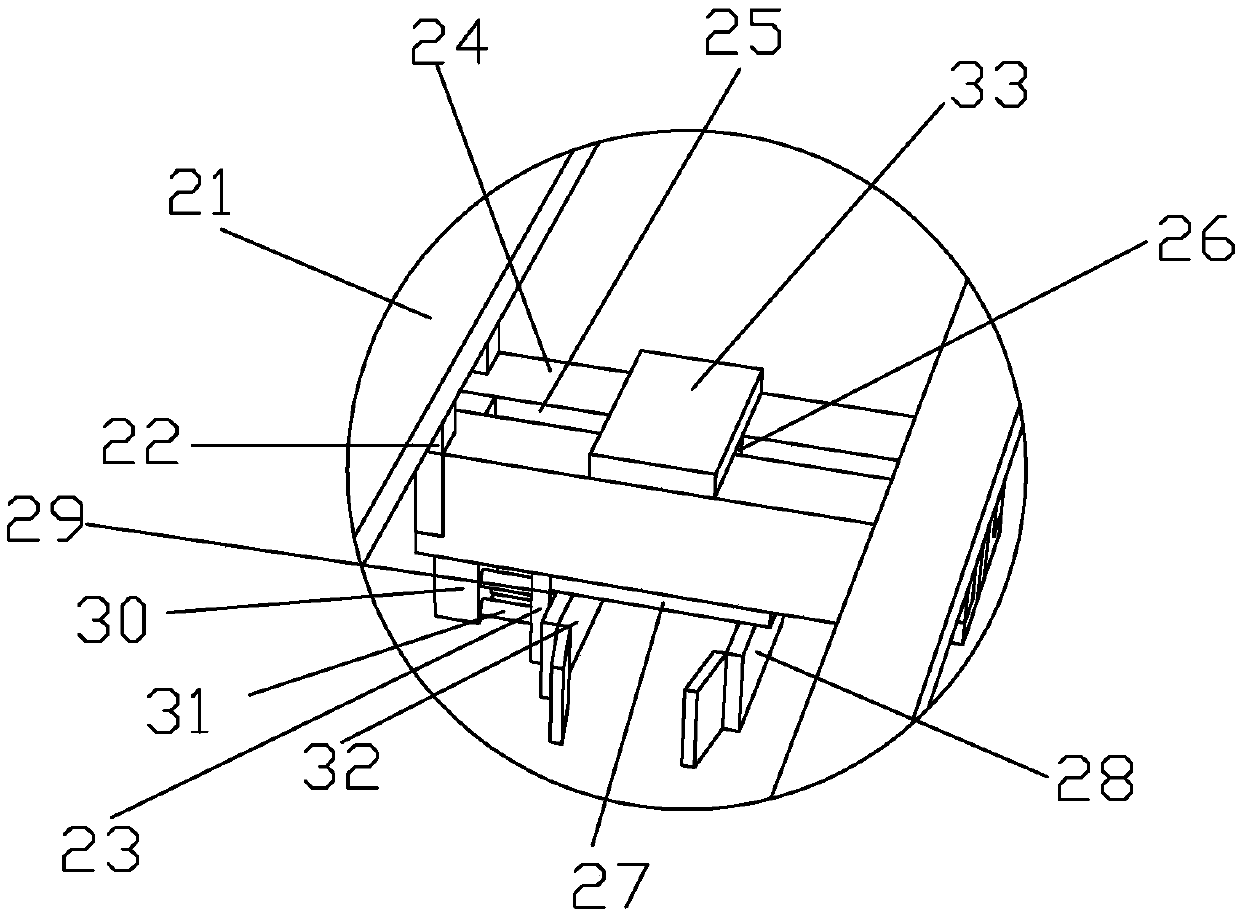

[0027] The specific embodiment of the present invention: open the first transport plate 35 and the second transport plate 36, evenly prevent the hardware accessories on the first transport plate 35, the hardware accessories enter the oil guide plate 5 along the ramp structure 37, open and slide Mechanism 17, and clamping mechanism 18, after clamping the hardware accessories on the oil guide plate 5, move along the sliding frame 21 and only rotate the plate 9, so that the hardware accessories rotate along the rotating plate 9, and open the oil injection mechanism 16 at the same time , the accessories are sprayed evenly, and the rotating blades rotate to prevent a large amount of oil from accumulating on the rotating disk 11 and affecting the rotation of the rotating device 7. After the oil is sprayed evenly, the clamping mechanism 18 clamps the inorganic accessories and continues to move along the sliding mechanism 17 On the second transportation board 36, the device is transpor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com