Spherical water film injection pipe fitting

A technology of water film and pipe fittings, applied in the direction of spray device, spray device, etc., can solve the problem of inability to spray multi-channel plane water film annular water film spray dead angle, etc., to reduce the spray dead angle and ensure the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Embodiments of the present invention are described in further detail below in conjunction with the accompanying drawings:

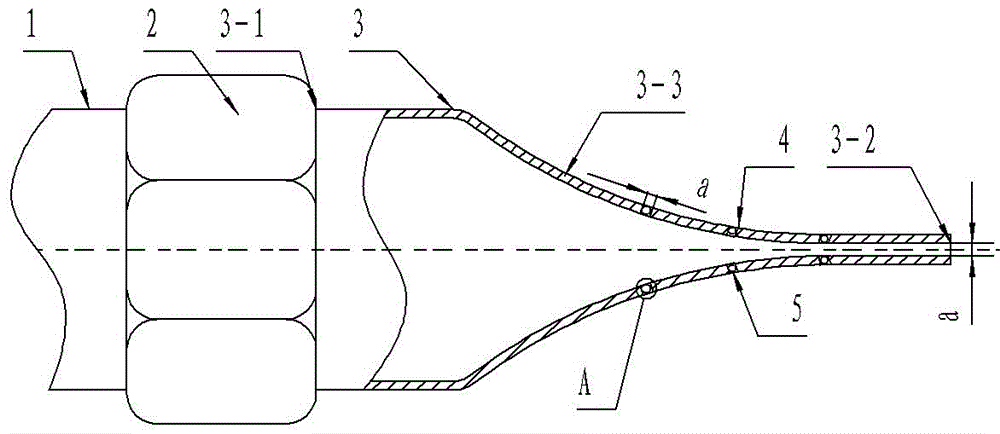

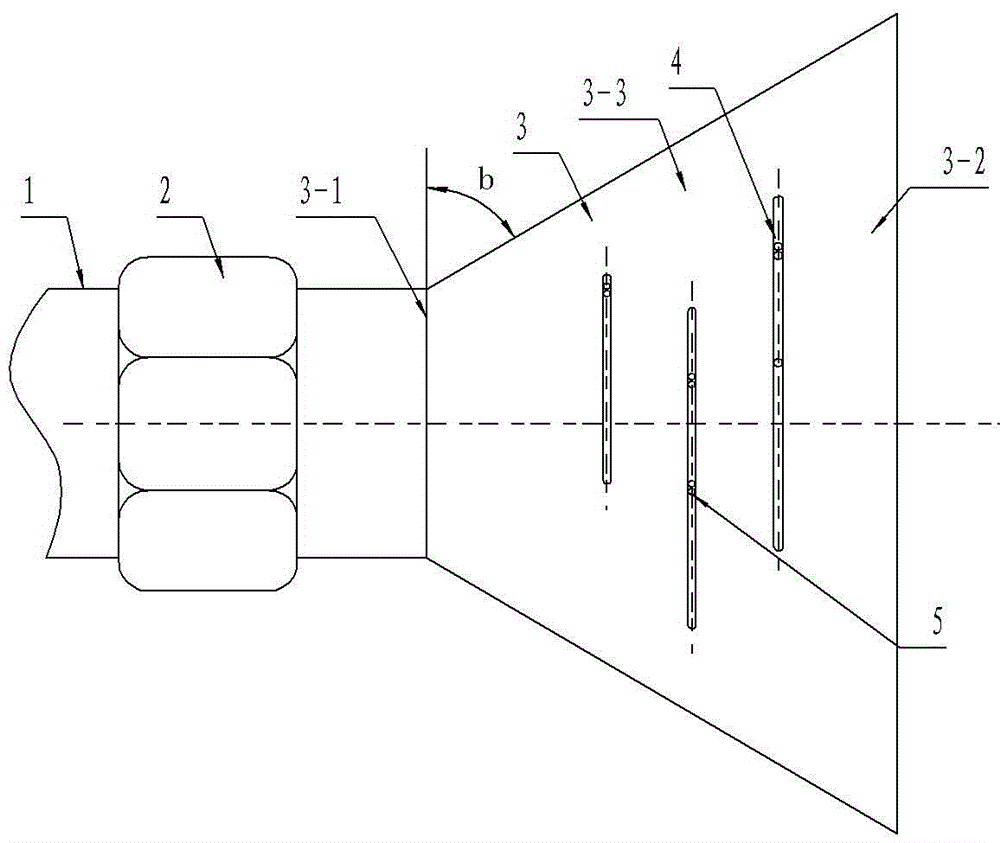

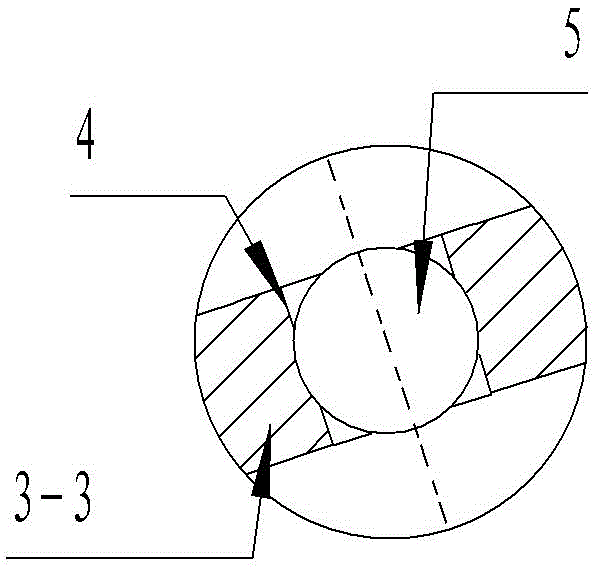

[0013] Such as figure 1 , figure 2 , image 3 The shown spherical water film injection pipe fitting, spherical water film injection pipe fitting, it comprises base pipe 1, base pipe 1 is connected by screw 2 spray head 3, spray head 3 is provided with flat section 3-3, and flat section 3-3 is from Near the water inlet end 3-1 to the water outlet end 3-2, it is gradually flattened, and one side of the spray head 3 is fan-shaped, so that the sprayed water can be flat and thin water film type. The inclination angle b of the spray head 3 sector is 60°. The minimum width a of the flat position of the water outlet end 3-2 of the spray head 3 is a=0.85 mm, which ensures the stability of the water outlet. There are many long holes 4 on the flat section 3-3, and the width of the long holes 4 is a, where a=0.85mm, so that a plurality of plane water film...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com