Machining method for spherical water film injection head

A processing method and spray head technology, which are applied to spray devices, spray devices, etc., can solve the problem of inability to spray multiple plane thin water films, and achieve the effect of reducing spray dead angles and meeting process requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

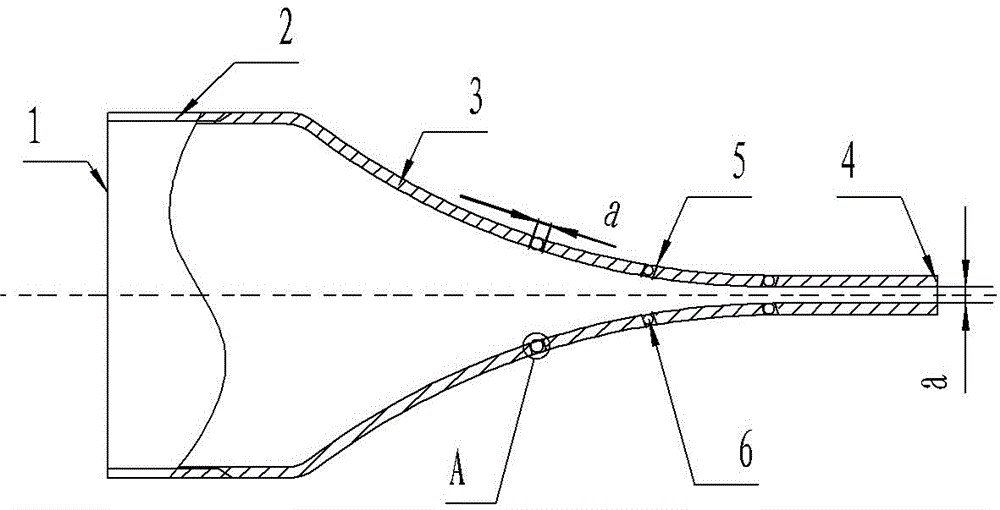

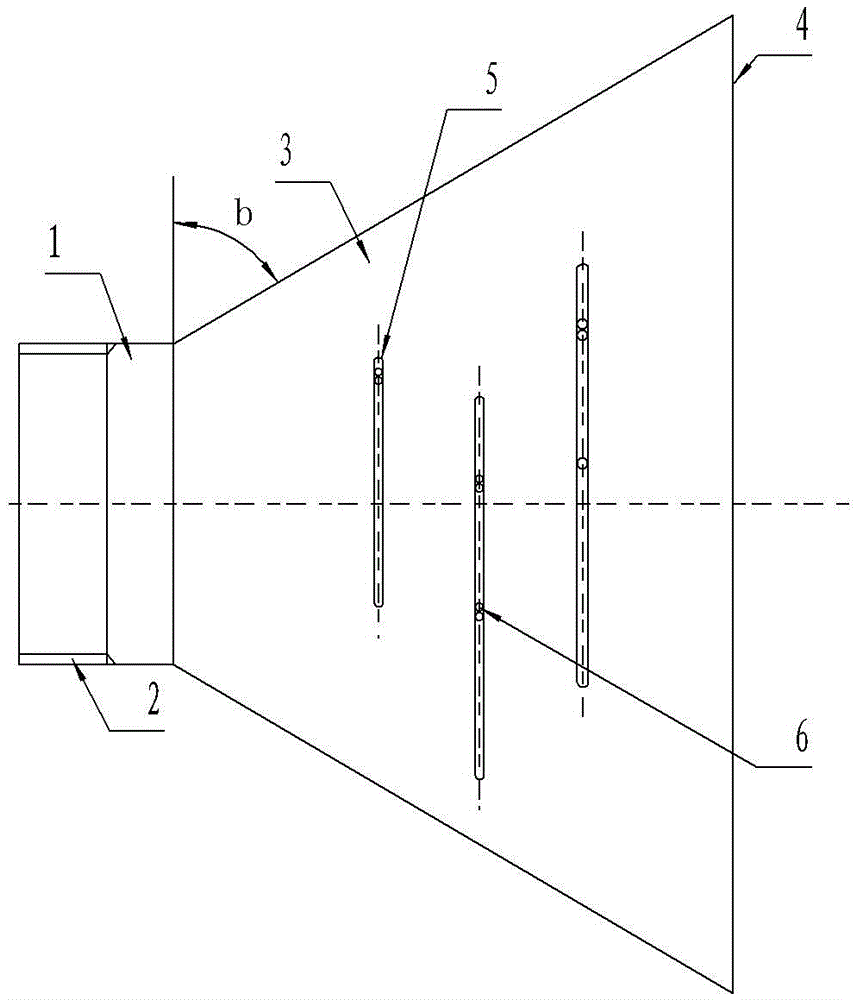

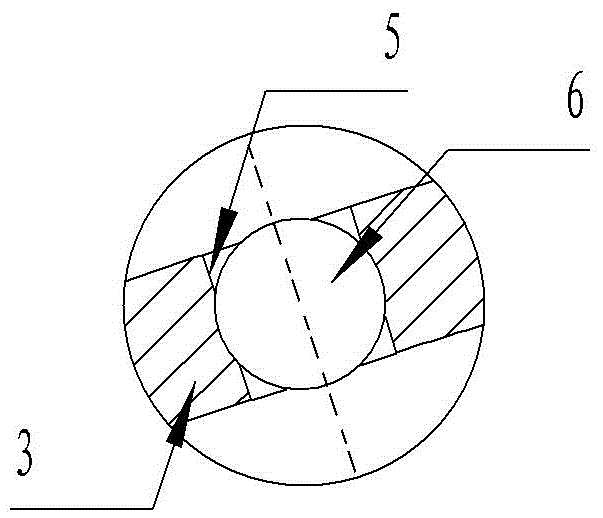

[0015] The processing method of this spherical water film spray head comprises processing a kind of spherical water film spray head, such as figure 1 , figure 2 , image 3 The shown spherical water film spray head includes a spray body, the water outlet end 1 of the spray body is provided with an external thread 2, the spray body is provided with a flat section 3, and the flat section 3 is gradually flattened from near the water inlet end 1 to the water outlet end 4, and the spray One side of the main body is fan-shaped, so that the sprayed water can be flat and thin water film. The inclination angle b of the spray body sector is 60°. The minimum width a of the 4 flat positions of the water outlet end of the jet body, a=0.85 mm, ensures the stability of the water outlet. There are many long holes 5 on the flat section 3, the width of the long holes 5 is a, a=0.85 mm, and multiple plane water films can be sprayed on the flat section 4, so that what the whole spray head spra...

Embodiment 2

[0022] Spherical water film nozzle such as figure 1 , figure 2 , image 3 , as in Example 1. The processing steps include: put cemented carbide powder into the mold for sintering, the mold is equipped with a flat position, a long hole position, and a ball position, and the long hole position is provided with an arc surface partition, and the concave position of the long hole position The groove part is separated from the ball position, and the thickness of the partition plate is 0.15 mm, which is sintered, and then combined with the part with the threaded section for sintering.

[0023] In other embodiments, according to the diameter of the water outlet pipe, the width at the minimum flat position of the water outlet end of the spray head may be any value from 0.6 mm to 1.3 mm. The thickness of the separator in the mold can also be any value between 0.1 mm and 0.2 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com