Reference electrode-free GaN-based pH sensor based on groove structure and manufacturing method thereof

A reference electrode and pH sensor technology, which is applied in the field of GaN-based pH sensor without reference electrode and its preparation, can solve the problems of oxide/aluminum gallium nitrogen interface defects, surface contamination, transfer curve hysteresis, etc., and achieve improvement Long-term reliability, solving slow response speed, and improving detection sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

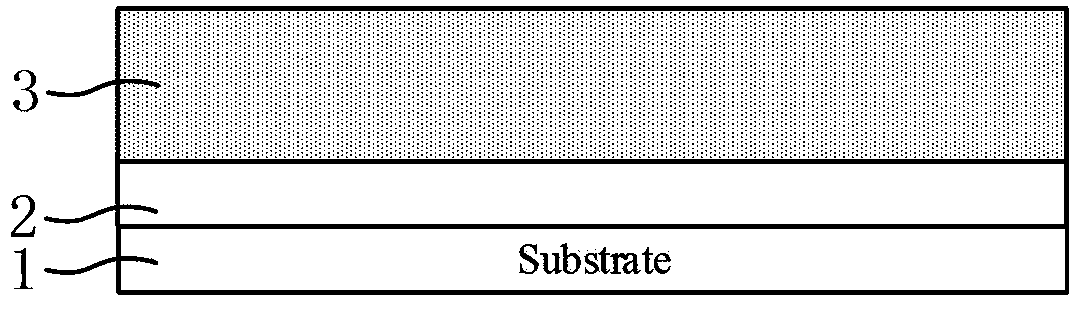

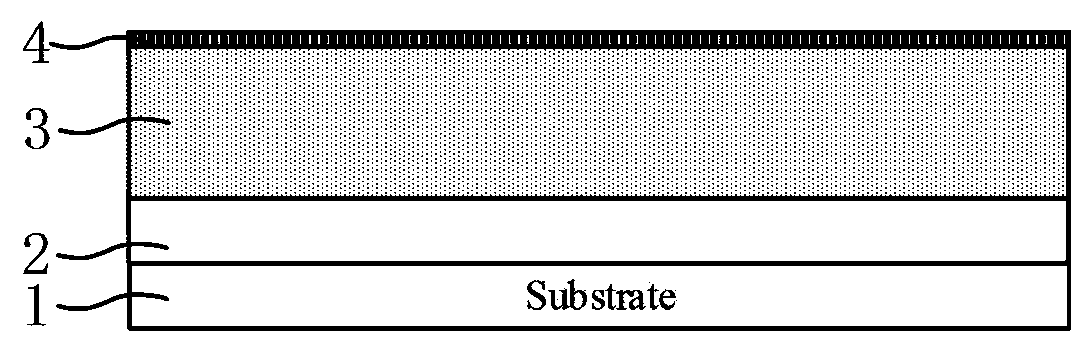

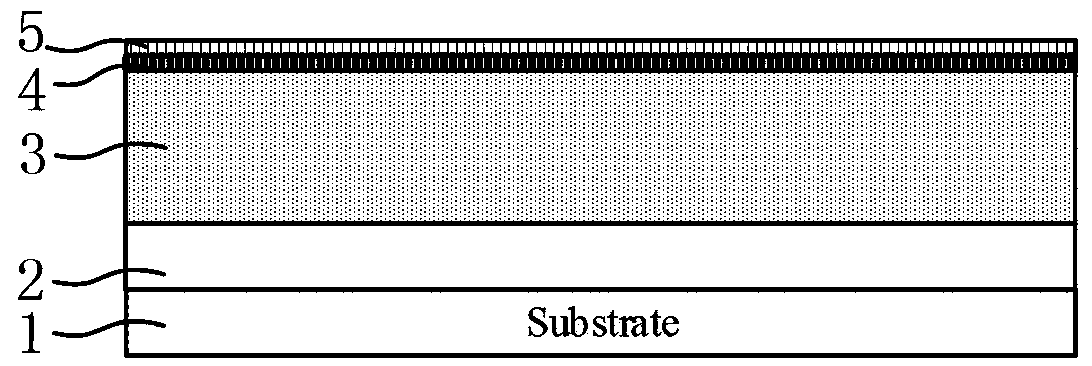

[0043] Such as Figure 7 As shown, a GaN-based pH sensor based on a groove structure without a reference electrode, its structure includes a substrate 1 from bottom to top; a stress buffer layer 2; a GaN epitaxial layer 3; a thin AlGaN barrier layer with low aluminum composition 4; AlN insertion layer 5; secondary growth AlGaN thin barrier layer with high aluminum composition 6: grooves are formed in the middle of thin AlGaN barrier layer 6 with high aluminum composition; high-sensitivity detection material 7: deposited and filled with high aluminum composition In the groove of the AlGaN thin barrier layer 6 ; ohmic contact electrode 8 : ohmic electrodes are formed at both ends of the high-sensitivity detection material 7 ; packaging material 9 .

[0044] Wherein, the substrate 1 is any one of Si substrate 1, sapphire substrate 1, silicon carbide substrate 1, and GaN self-supporting substrate 1; the stress buffer layer 2 is AlN, AlGaN, GaN Any one or a combination of; the thi...

Embodiment 2

[0055] The structural diagram of embodiment 2 is similar to that of embodiment 1, except that the groove structure is not obtained by selective area growth, but by dry or wet etching.

[0056] In addition, it should be noted that the drawings of the above embodiments are only for illustrative purposes, and thus are not necessarily drawn to scale.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap