Automatic textile machine

A technology for textile machines and textile racks, which is applied in textiles, looms, textiles, and papermaking. It can solve problems such as single function, non-adjustable height of textile machines, and inability to realize automation. It achieves single-function, adjustable height, The effect of convenient transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

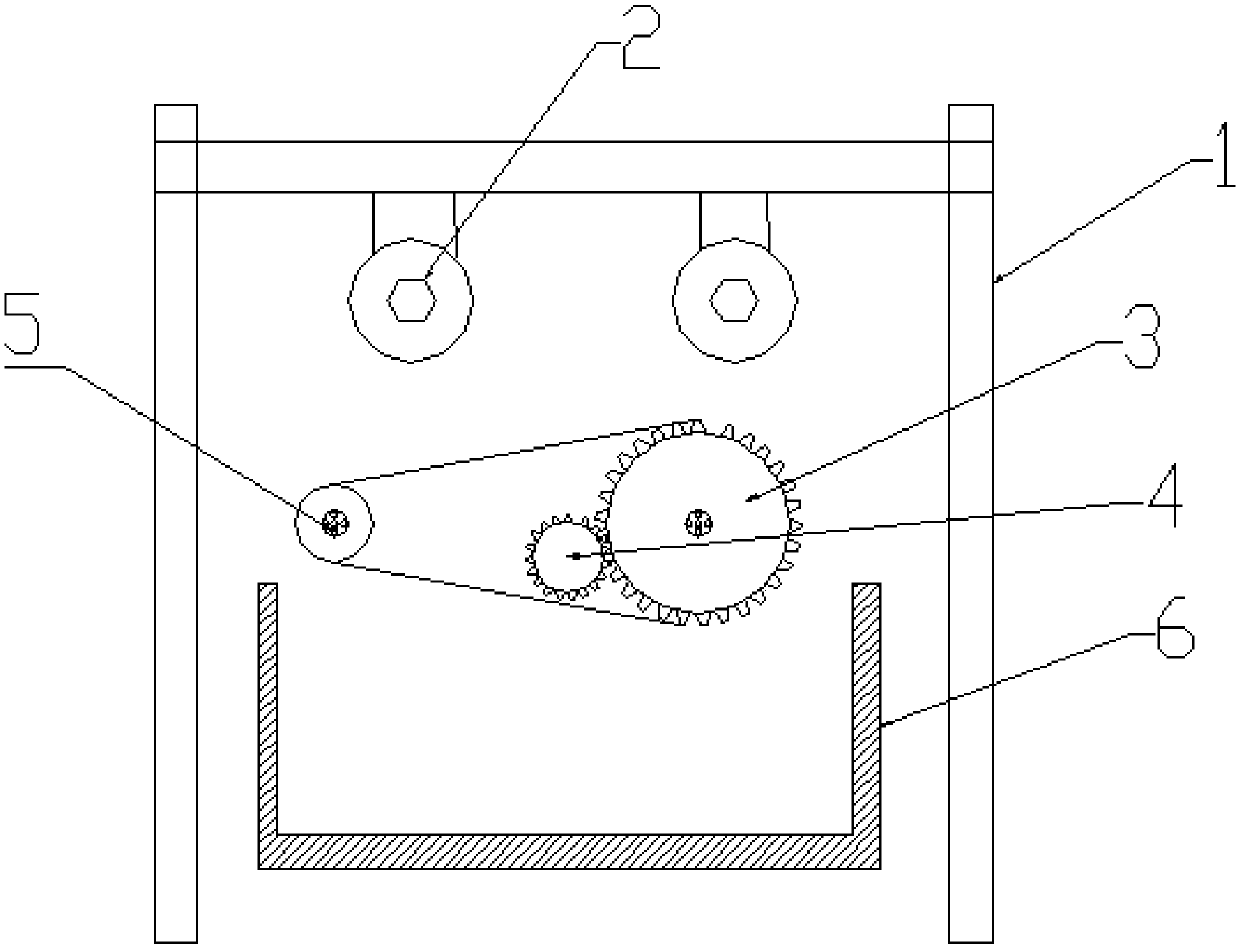

[0022] Embodiment 1: an automatic textile machine, comprising a textile frame 1 with an inverted U-shaped structure, a cloth measuring device 2 is installed on the top of the textile frame 1, and the bottom of the cloth measuring device 2 is a textile mechanism, comprising The driving wheel 3 and the driven wheel 5, the deburring device 4 is close to the driving wheel 3; the lower part of the weaving mechanism is a temperature control device 6. The said textile frame 1 can be provided with a dust cover. The cloth measuring device 2 is detachably connected to the textile frame 1 . The temperature control device 6 has a concave structure. The textile frame 1 is composed of a crossbar and a column, and the two ends of the crossbar and the column are connected by plugging. The temperature control device 6 includes an infrared temperature detector. The diameter of the driving wheel 3 is three times the diameter of the driven wheel 5 . The height of the column of the textile fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com