Municipal bridge guardrail washing device and use method thereof

A cleaning device and guardrail technology, which is applied in cleaning methods, road surface cleaning, construction, etc., can solve problems such as difficult cleaning, dust sticking to guardrails, and affecting the appearance of guardrails

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

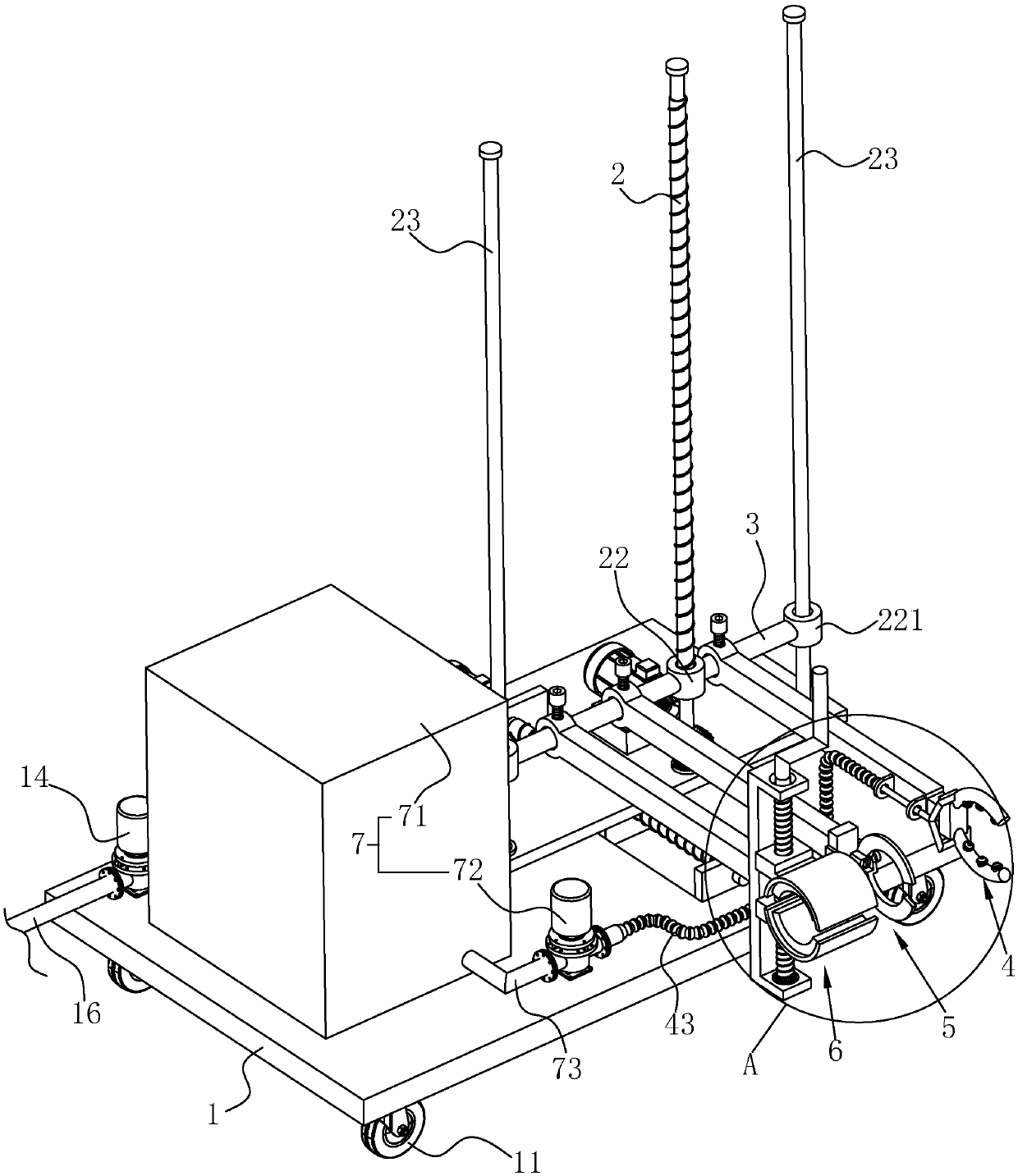

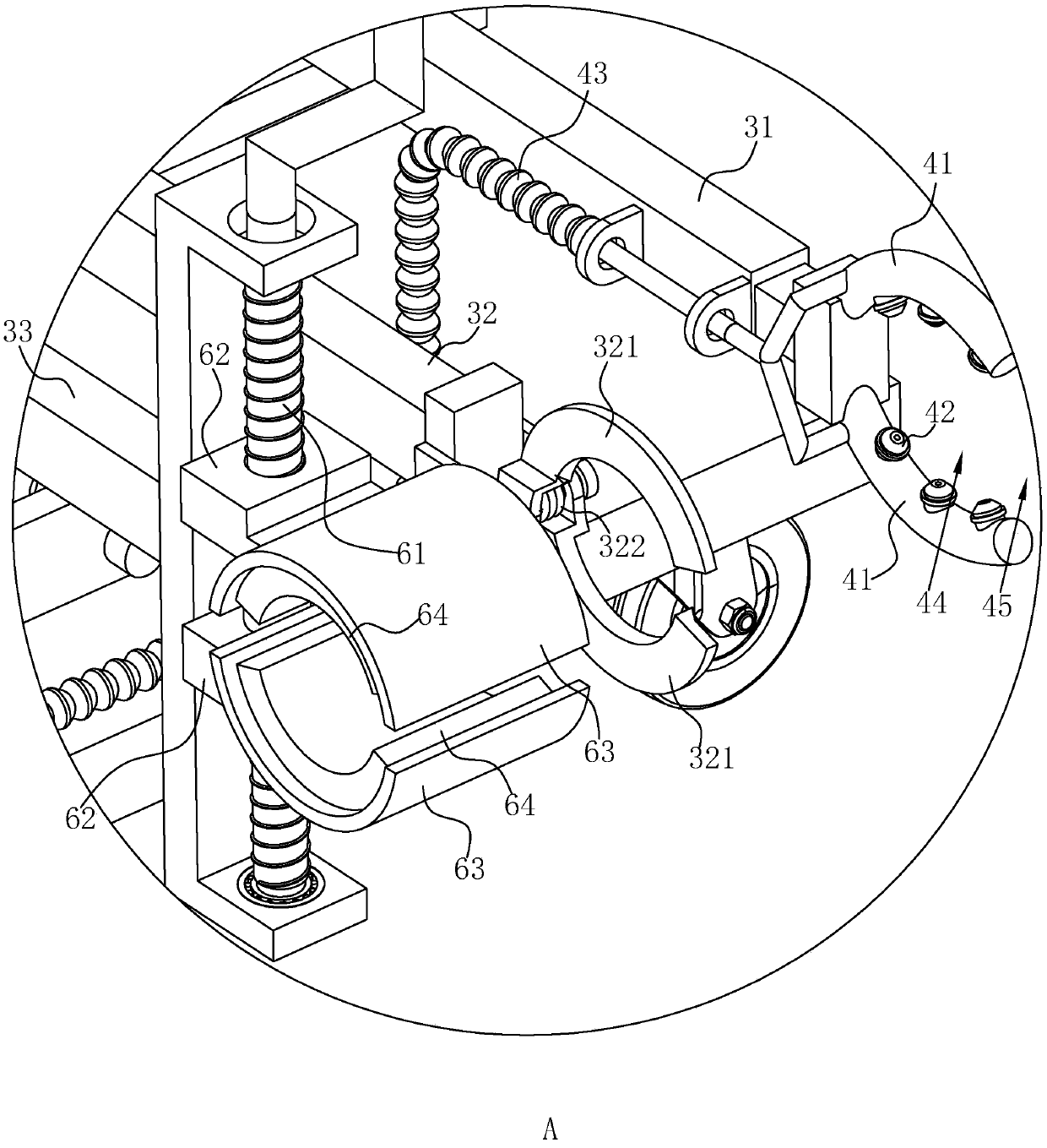

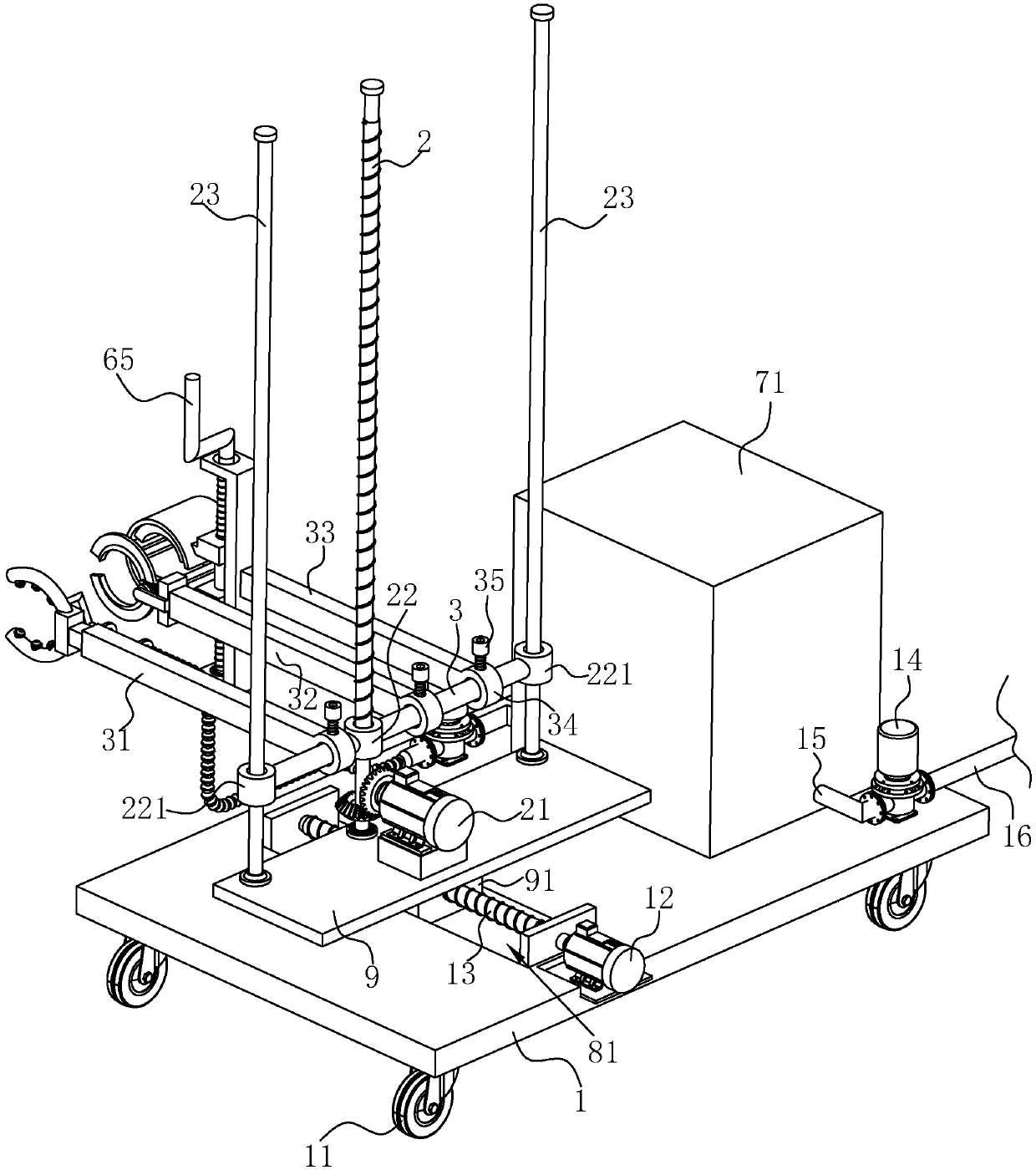

[0042] Such as figure 1 , 3 As shown, a municipal bridge guardrail cleaning device includes a base plate 1 and rollers 11 arranged at four corners of the base plate 1. The shape of the base plate 1 is rectangular, and the base plate 1 is rotated to be provided with a vertically upwardly extending first A threaded screw 2, that is, a rolling bearing is arranged on the bottom plate 1, and the first leading screw 2 passes through the inner ring of the rolling bearing and is in an interference fit with the rolling bearing; the bottom plate 1 is provided with a rotating motor 21 for driving the rotation of the first leading screw 2. In this embodiment, the output shaft of the rotating motor 21 is perpendicular to the length direction of the first leading screw 2, and the end of the output shaft of the rotating motor 21 is coaxially provided with a bevel gear, and the first leading screw 2 is close to the bar on the bottom plate 1 side. Another bevel gear meshed with the bevel gea...

Embodiment 2

[0057] A method for using a municipal bridge guardrail cleaning device, comprising the following steps:

[0058] Step 1, put the nozzle of the water suction pipe 16 into the river, start the second water pump 14, so that the water is transported into the water storage tank 71;

[0059] Step 2, pushing the base plate 1 onto the municipal bridge, so that the length direction of the base plate 1 and the length direction of the railing 101 are parallel to each other;

[0060] Step 3: start the driving motor 12, let the moving plate 9 move towards the side close to the guardrail, let a section of the railing 101 be between the piercing ring 44 formed by the two arc-shaped tubes 41, start the first water pump 72 to pump the water from the high-pressure nozzle 42 places are sprayed onto the railing 101;

[0061] Step 4, move the two scrapers 321 to the railing 101 to surround the guardrail and make the railing 101 fit the scraper 321, and move the bottom plate 1 to allow the two scr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com