Anti-icing voltage-sharing plate

An anti-icing and pressure plate technology, applied in the direction of suspension/strain insulators, electrical components, insulators, etc., can solve the problem of the size of the tower window, the increase of the line corridor channel, the difficulty of effectively protecting the safety of the power grid, and the inability of the power grid to be effectively deployed To achieve the effect of delaying the icing package time, increasing the icing flashover voltage, reducing the window size and line corridor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

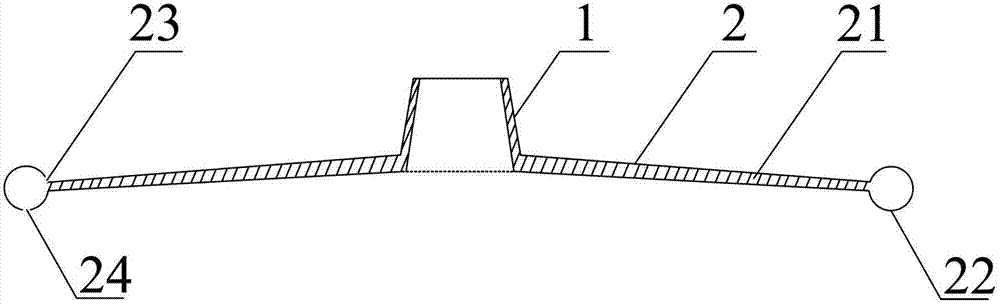

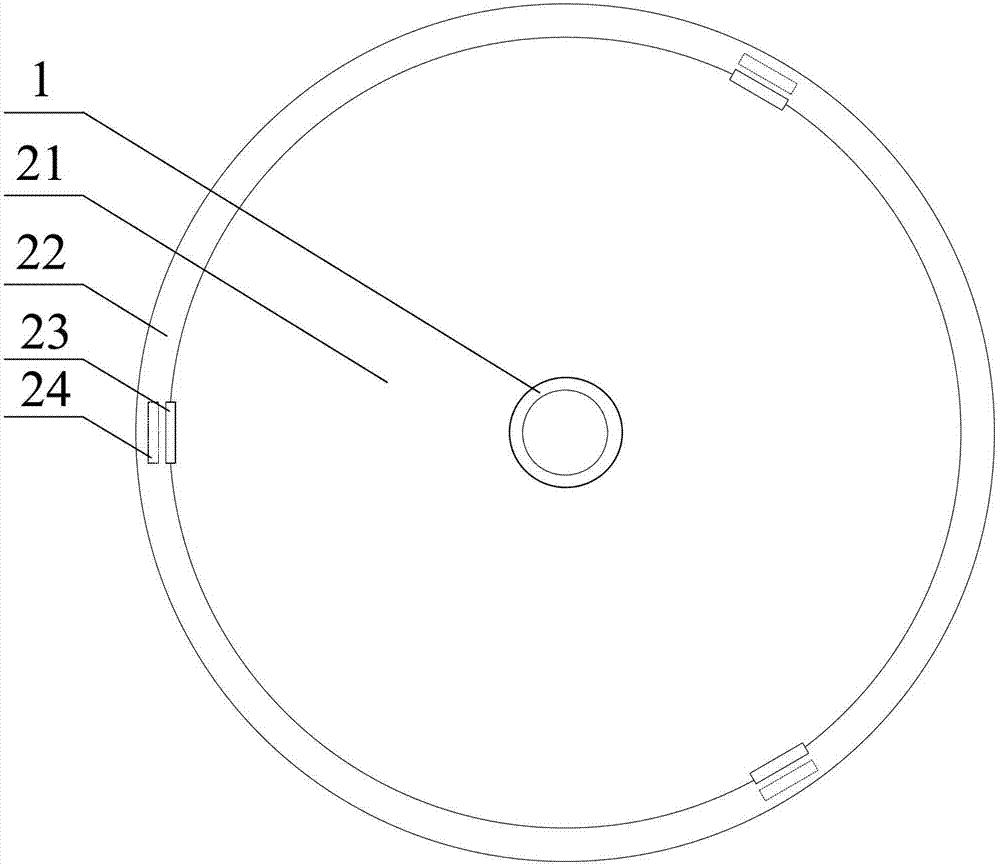

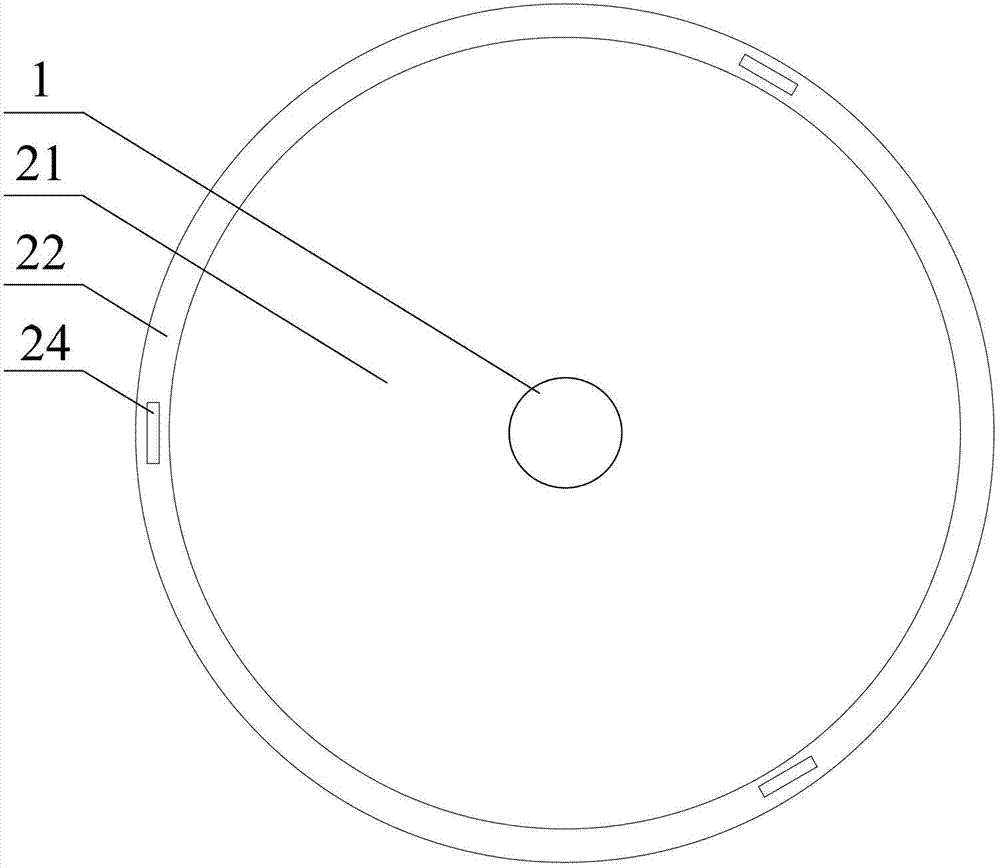

[0022] See Figure 1~3 , figure 1 Shown is a specific embodiment of the present invention. In the anti-icing equalizing plate of this embodiment, one of the components of the cover 1 is in the shape of a bowl, which is cut and welded from a 45# plate. The outer diameter of the upper bottom surface is φ80mm, and the lower bottom surface is the hood caliber φ100mm, and the height is 80mm. Another component disc 2 such as figure 1 As shown, there is an umbrella-shaped disk body 21 with a center hole so that it has a center hole. The outer periphery of the umbrella-shaped disc body 21 is a ring body 22 with a circular cross section. The disc 21 inside the ring 22 is like figure 2 As shown, drainage holes 23 are evenly distributed. The bottom surface of the ring body 22 is like image 3 As shown, the lower edge drainage holes 24 are evenly distributed. The aperture size of the central hole of the disc 2 matches the aperture size of the cover body 1. The cover body 1 is fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com