Solid-liquid separation equipment for accelerating liquid flow

A solid-liquid separation and liquid flow technology, which is applied in the direction of separating sediments by centrifugal force, can solve the problems of accelerated liquid flow and incomplete solid-liquid separation, and achieve the effect of avoiding cross flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

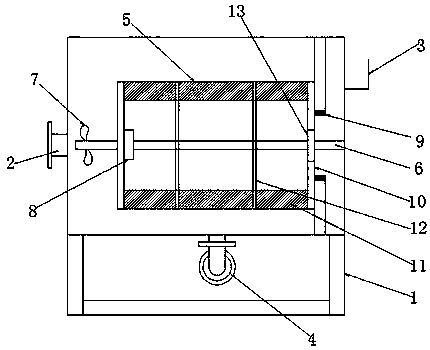

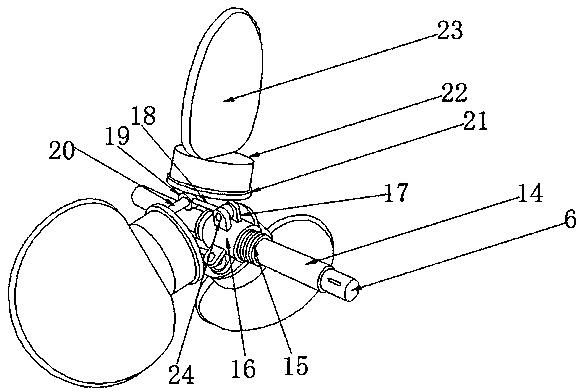

[0024] Embodiment one, such as Figure 1-3 As shown, a solid-liquid separation device for accelerating liquid flow according to an embodiment of the present invention includes a main water tank 1, a water inlet pipe 2 is provided on one side of the main water tank 1, and a water inlet pipe 2 is provided on the other side of the main water tank 1. Outlet weir groove 3, the inner lower end of the main body water tank 1 is provided with a return pipe 4, the inside of the main body water tank 1 is provided with an inertial separation mechanism 5, and the middle position of the inertial separation mechanism 5 is provided with a movable shaft 6, so One end of the movable shaft 6 is provided with a hydraulic drive device 7 , and one end of the inertial separation mechanism 5 close to the hydraulic drive device 7 is provided with a rotating device 8 .

Embodiment 2

[0025] Embodiment two, such as figure 1 As shown, a magnetic sealing device 9 is provided between the inertial separation mechanism 5 and the main water tank 1, and the hydraulic drive device 7 can use impact type, axial flow type and mixed flow structure, which can ensure that all solid-liquid mixtures are uniform Through the inertial separation mechanism 5.

Embodiment 3

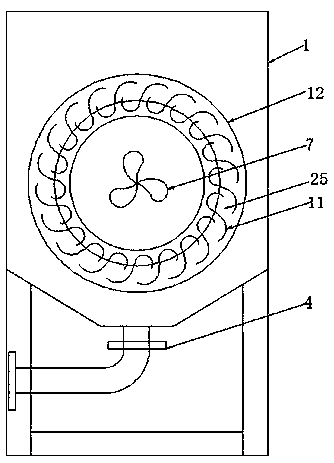

[0026] Embodiment three, such as Figure 1-2 As shown, the inertial separation mechanism 5 includes two sets of end plates 10, a number of arc-shaped guide vanes 11 are uniformly arranged between the two groups of end plates 10, and the arc-shaped guide vanes 11 pass through several fixed rings. 12 connections, the end plate 10 is provided with an outlet channel 13, the arc-shaped guide vanes 11 are in an S-like structure as a whole, and multiple sets of arc-shaped guide vanes 11 are evenly distributed on the circumference, and relying on the The fixing ring 12 forms a cylindrical structure, and the flow channel 25 is formed between the arc-shaped guide vanes 11 .

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap