Inertial solid-liquid separation device powered by water flow

A solid-liquid separation and power technology, applied in the direction of filtration separation, separation methods, chemical instruments and methods, etc., can solve problems affecting separation efficiency, clogging, etc., and achieve the effects of increasing efficiency, avoiding cross-flow, and avoiding clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

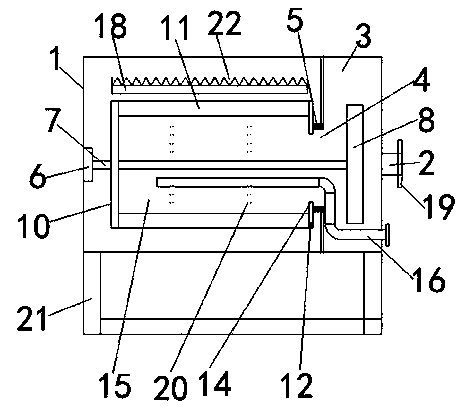

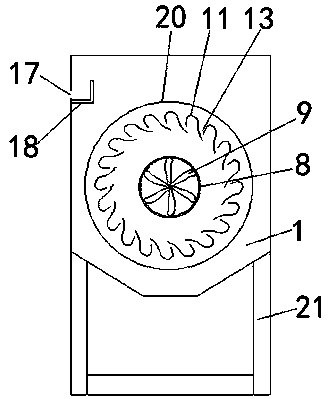

[0026] see Figure 1-4 According to an embodiment of the present invention, an inertial solid-liquid separation device using water flow as power includes a main water tank 1, a water inlet pipe 2 is provided on one side of the main water tank 1, and a cavity 3 is provided in the main water tank 1 , the cavity 3 is provided with a water outlet 4, the water outlet 4 is provided with a magnetic gasket 5, and the main water tank 1 is provided with a bearing 6 at an end far away from the cavity 3, and the bearing 6 is A rotating rod 7 is fixed, one end of the rotating rod 7 runs through the water outlet 4 and extends into the cavity 3, and a water retaining groove is fixed at one end of the rotating rod 7 in the cavity 3 8. A propeller blade 9 is arranged in the water retaining groove 8, a rotating plate 10 is fixed on the rotating rod 7, and a number of arc-shaped guide vanes 11 are uniformly fixed on one side of the rotating plate 10, and the arc A baffle 12 is provided at the e...

Embodiment 2

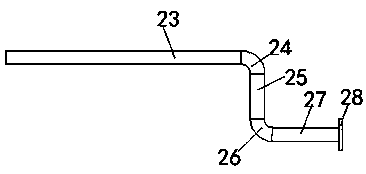

[0029] see Figure 1-3 , for the water inlet pipe 2, the water inlet pipe 2 is provided with a water inlet connection flange 19. It is convenient for the water inlet pipe 2 to be connected to an external water pipe. For the arc-shaped flow guide piece 11 , the outside of the arc-shaped flow guide piece 11 is fixedly connected by several connecting binding rings 20 . This makes the arc guide vane 11 more stable. For the main body water tank 1 , support legs 21 are provided under the main body water tank 1 . Make the main water tank 1 more stable. For the concentration adjustment mechanism 16, the concentration adjustment mechanism 16 includes a first catheter 23, the first catheter 23 is located in the separation chamber 15, and the first catheter 23 passes through the first arc. Shaped pipe 24 is connected with the second liquid guide tube 25, and described second liquid guide tube 25 is connected with the 3rd liquid guide tube 27 by the second arc tube 26 at one end away ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap